What is Ultrathin High Frequency PCB?

Ultrathin High Frequency PCB Supplier,Ultrathin high-frequency PCBs are specialized substrates designed for compact and high-performance electronic applications. With thicknesses typically ranging from fractions of a millimeter to a few millimeters, these PCBs offer reduced size and weight while maintaining excellent electrical performance in high-frequency circuits. They feature advanced materials with low dielectric constants and minimal signal loss, ensuring efficient signal transmission. Ultrathin high-frequency PCBs are favored in industries such as telecommunications, aerospace, and medical devices, where space constraints and high-speed data transmission are critical. Their compact design and superior electrical properties make them indispensable for modern electronic systems requiring miniaturization and high-frequency operation.

“Ultrathin High Frequency PCBs” represent an exceptionally slim class of printed circuit boards meticulously designed for high-frequency and microwave applications. These applications span various sectors, including communication devices, radar systems, and RF modules. Engineered to operate within the frequency range of hundreds of megahertz (MHz) to several gigahertz (GHz), these PCBs provide advanced solutions for contemporary electronic needs.

Highlighted features and applications include:

Sleek Design: Noteworthy for their slender profile, these PCBs significantly minimize both the size and weight of the circuit board—particularly advantageous for devices uce energy losses during signal transmission at high frequencies.

Material Precision: Leveraging specialized materials such as with stringent space and weight constraints.

High-Frequency Expertise: Tailored to efficiently handle high-frequency signals, Ultrathin High Frequency PCBs find extensive application across industries, especially in communication and radar systems.

Efficient Signal Handling: Crafted with low-loss materials, these PCBs effectively redpolytetrafluoroethylene (PTFE), Ultrathin High Frequency PCBs precisely cater to the specific demands of high-frequency applications.

Effective RF Shielding: Equipped with robust RF shielding capabilities, these PCBs excel in minimizing electromagnetic interference, ensuring stable signal transmission.

In essence, Ultrathin High Frequency PCBs offer a tailored and efficient solution for high-frequency signal processing in diverse electronic applications. This slim and precise option addresses the modern technological demands across various industries, providing a reliable foundation for advanced electronic systems.

Ultrathin High Frequency PCB Supplier

Can You Grasp the Complexity of Ultrathin High-Frequency PCBs?

These specialized printed circuit boards are intricately crafted to manage high-frequency signals within the microwave frequency range. The complexity of their design arises from the need to balance various critical factors:

Ultra-Thin Design: Achieving an exceptionally slim profile while maintaining structural integrity presents a significant challenge. The design must consider both the mechanical stability and heat dissipation requirements of the PCB.

High-Frequency Performance: Ensuring efficient transmission of high-frequency signals demands low signal loss and minimal impedance mismatch. This requires precise material selection and optimization of the PCB’s electrical properties.

RF Shielding: Effective shielding to minimize electromagnetic interference is crucial. This involves incorporating shielding layers and techniques to uphold signal integrity in high-frequency environments.

Manufacturing Processes: The fabrication of Ultrathin High-Frequency PCBs involves advanced techniques like precise etching, drilling, and lamination. Achieving uniformity and consistency in these processes is essential for reliable performance.

Application Specifics: Addressing the unique requirements of diverse applications, such as communication devices, radar systems, and RF modules, adds an extra layer of complexity. Each application may have specific demands that must be carefully considered in the PCB design.

Understanding and navigating these complexities demands expertise in high-frequency electronics, materials science, and PCB manufacturing. Engineers and designers working on Ultrathin High-Frequency PCBs must skillfully manage the intricate interplay of these factors to meet the stringent demands of modern electronic applications.

Do Ultrathin High-Frequency PCBs Truly Enhance Signal Transmission?

Ultrathin high-frequency PCBs are intricately engineered to improve signal transmission, particularly in applications involving high-frequency and microwave frequencies. Their effectiveness is derived from several key features:

Low Signal Loss:

These PCBs utilize low-loss dielectric materials, reducing signal loss significantly, a crucial factor at higher frequencies.

Lower Dielectric Constant:

Utilizing materials with reduced dielectric constants accelerates signal propagation, mitigating both delays and distortion.

Precise Impedance Control:

Ultrathin high-frequency PCBs enable precise control of impedance, crucial for preventing signal reflections and ensuring efficient power transfer.

Minimized Crosstalk:

Careful design and shielding techniques minimize crosstalk between adjacent signal traces, enhancing overall signal quality.

Compact Design and Size Reduction:

The use of thinner materials facilitates compact designs, essential in applications where space is limited, while also reducing parasitic capacitance and inductance.

Enhanced Thermal Management:

These PCBs often exhibit improved thermal conductivity, aiding in efficient heat dissipation, vital in high-frequency applications with increased power density.

In summary, ultrathin high-frequency PCBs excel in optimizing signal transmission by addressing challenges associated with higher frequencies. Their intricate design, featuring low-loss materials, controlled impedance, and minimized crosstalk, contributes to their effectiveness in demanding applications. Additionally, their ability to support compact designs and manage heat efficiently further enhances their suitability for high-frequency and microwave applications.

Are There Different Types of Ultrathin High-Frequency PCBs to Explore?

Ultrathin high-frequency PCBs exhibit a wide variety of types, each finely tuned for specific applications and industries. These PCBs, crafted to ensure optimal signal performance at high frequencies, present a rich array of options. Let’s explore the unique attributes of ultrathin high-frequency PCBs, encompassing flexible options ideal for wearables and rigid configurations specifically designed for aerospace and telecommunications.

Flexible Ultrathin High-Frequency PCBs:

These PCBs stand out for their adaptability, employing thin and flexible substrates. Well-suited for applications with spatial constraints, like wearables, they seamlessly integrate into various materials, enabling use in smart clothing, fitness trackers, and medical wearables.

Rigid Ultrathin High-Frequency PCBs:

Contrastingly, rigid ultrathin high-frequency PCBs maintain a fixed form, making them ideal for industries demanding stability and durability. Aerospace, telecommunications, and other sectors that prioritize rigid structures leverage these PCBs for maintaining signal integrity in high-frequency communication equipment.

Multilayer Ultrathin High-Frequency PCBs:

Versatile and applicable across various industries, multilayer PCBs consist of multiple copper traces and thin insulating layers. They find use in telecommunications infrastructure, high-speed data transfer, and networking equipment, offering increased routing density and enhanced signal integrity.

Hybrid Ultrathin High-Frequency PCBs:

Hybrid PCBs seamlessly combine attributes from both flexible and rigid designs, offering an optimal equilibrium between flexibility and stability. Particularly valued in aerospace applications, where weight and space concerns take precedence, these hybrid PCBs deliver essential adaptability to meet precise requirements.

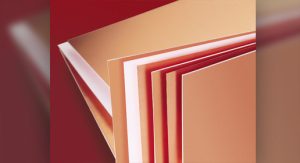

High-Frequency Materials:

Beyond structure, the choice of materials is pivotal. Specialized high-frequency materials, like PTFE or ceramic-filled materials, contribute to low dielectric loss and consistent signal transmission at elevated frequencies.

Low-Loss Ultrathin High-Frequency PCBs:

Specifically crafted for scenarios where signal preservation is paramount, low-loss ultrathin PCBs utilize materials with exceptionally low dissipation factors. These specialized PCBs hold a critical position in telecommunications, high-frequency RF devices, and the development of 5G infrastructure by facilitating highly efficient signal transmission. Their design focuses on minimizing any potential signal loss, making them instrumental in applications requiring pristine signal integrity and high-frequency performance.

In summary, the diverse landscape of ultrathin high-frequency PCBs offers finely tuned solutions for a spectrum of industries. From flexible options catering to wearables to rigid designs serving aerospace and telecommunications, these PCBs showcase versatility and specialized features, meeting the distinctive needs of contemporary technology applications. Ongoing innovations in materials and design techniques continue to broaden the horizons for optimizing signal transmission in diverse and demanding environments.

How Do Ultrathin High-Frequency PCBs Compare to Traditional PCBs?

The contrast between ultrathin high-frequency PCBs and traditional PCBs is pronounced, encompassing variations in design, materials, and performance characteristics. This divergence gains heightened significance in situations where the interplay of space limitations and high-frequency demands becomes pivotal.

Thickness and Flexibility:

Ultrathin High-Frequency PCBs: Known for their streamlined thickness and potential flexibility, especially in designs attuned to applications constrained by limited space.

Traditional PCBs: Offer a spectrum of thicknesses, typically adhering to rigidity, though flexible options exist.

Materials:

Ultrathin High-Frequency PCBs: Employ specialized materials with low dielectric constants and minimal dissipation factors to optimize signal integrity at higher frequencies.

Traditional PCBs: Leverage a diverse material range, with commonly used FR-4 being prevalent but potentially falling short in high-frequency performance compared to ultrathin counterparts.

Signal Integrity and Loss:

Ultrathin High-Frequency PCBs: Excel in preserving signal integrity, minimizing signal loss, making them ideal for high-frequency applications.

Traditional PCBs: While suitable for various applications, they may experience higher signal loss at elevated frequencies.

Applications:

Ultrathin High-Frequency PCBs: Tailored for applications demanding both high-frequency performance and compact designs, such as wireless communications, radar systems, and 5G infrastructure. Their prowess lies in meeting the challenges posed by limited space while delivering enhanced signal capabilities.

Traditional PCBs: Ubiquitous across diverse electronic applications, they may not match the high-frequency performance or compact design capabilities inherent in ultrathin PCBs.

Cost Considerations:

Ultrathin High-Frequency PCBs: Often involve higher manufacturing costs due to specialized materials and precision requirements.

Traditional PCBs: Tend to be more cost-effective for general electronic applications.

In summary, ultrathin high-frequency PCBs excel in scenarios where space constraints and high-frequency demands are crucial. Their specialized materials and focus on signal integrity make them optimal for applications requiring top-notch performance at higher frequencies and in compact electronic devices.The decision between ultrathin high-frequency PCBs and traditional PCBs is contingent upon the unique requirements of the application, taking into account variables like cost, performance expectations, and design flexibility. This choice hinges on a nuanced evaluation of factors that cater to the specific demands of the project at hand, ensuring a judicious balance between economic considerations, desired performance levels, and the adaptability of the PCB design.

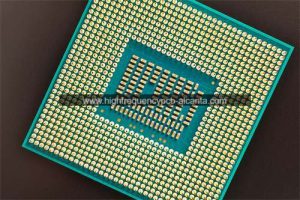

Are Ultrathin High-Frequency PCBs Essential in Motherboards and Advanced Electronics?

Ultrathin high-frequency PCBs emerge as indispensable components in the intricate landscape of motherboards and advanced electronic devices. Their incorporation is crucial for meeting the escalating demands for heightened performance, faster data transmission, and unwavering reliability in contemporary electronics.

High-Frequency Signal Transmission:

Tailored for elevated frequencies, ultrathin high-frequency PCBs are engineered to facilitate the efficient transfer of signals within motherboards and advanced electronic devices. This is particularly crucial for components like processors, memory modules, and interfaces requiring rapid data transmission.

Compact Design and Miniaturization:

The slim and flexible nature of ultrathin PCBs permits a more compact and space-efficient design. In motherboards and advanced electronics, where spatial constraints are prominent, the capacity to minimize PCB size contributes to streamlined and smaller form factors, especially beneficial for portable devices.

Improved Signal Integrity:

With a focus on minimizing signal loss, ultrathin high-frequency PCBs contribute to enhanced signal integrity. This is vital in motherboards where reliable communication among various components is paramount, fostering stable data transmission and reducing electromagnetic interference.

High-Speed Data Interfaces:

Addressing the needs of high-speed data interfaces like USB 3.1, PCIe, and advanced memory interfaces, ultrathin high-frequency PCBs ensure optimal performance without signal degradation.

5G and Wireless Connectivity:

The surge in 5G technology amplifies the importance of high-frequency PCBs. Motherboards and electronic devices with wireless connectivity benefit from these PCBs, enabling efficient signal transmission in the high-frequency bands associated with 5G and other wireless standards.

Thermal Management:

Beyond signal transmission, ultrathin high-frequency PCBs often incorporate materials with enhanced thermal conductivity. This is crucial for advanced electronics, where efficient thermal management is vital to maintain reliability and prevent performance degradation due to heat.

Future-Proofing for Emerging Technologies:

The adaptability of ultrathin high-frequency PCBs positions electronic devices for future technologies. Their capacity to handle high frequencies ensures that hardware remains relevant and capable as technological advancements unfold.

In essence, ultrathin high-frequency PCBs serve as indispensable elements in the intricate architecture of motherboards and advanced electronic devices. Their role spans from facilitating high-speed signal transmission to enabling compact designs, preserving signal integrity, and contributing to efficient thermal management. As electronic systems advance, the importance of ultrathin high-frequency PCBs grows, ensuring that modern applications meet the ever-evolving standards of performance and reliability.

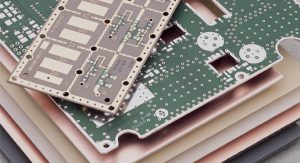

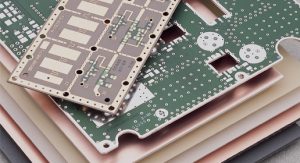

What Makes the Structure and Production Technologies of Ultrathin High-Frequency PCBs Marvelous?

The structure and production technologies employed in ultrathin high-frequency PCBs are truly remarkable, showcasing several noteworthy features:

Compact Design: These PCBs are characterized by an exceptionally slim structure, achieved through advancements in material technology and manufacturing processes. This slim profile caters to applications with stringent size and weight constraints, such as aerospace components and portable electronic devices.

Dielectric Enhancements: The utilization of cutting-edge dielectric materials with low dissipation factors and excellent thermal stability is a standout feature. These materials significantly improve signal integrity, minimize signal loss, and contribute to the overall high-frequency performance of the PCB.

Specialized Substrates: Ultrathin high-frequency PCBs often incorporate specialized substrates like polytetrafluoroethylene (PTFE) to meet the specific demands of high-frequency applications.

Signal Efficiency: These PCBs are designed to minimize signal loss, ensuring efficient signal transmission at higher frequencies. Precise impedance control is achieved through advanced manufacturing techniques, maintaining consistent electrical characteristics throughout the circuit.

Layer Optimization: Ultrathin high-frequency PCBs commonly feature a multilayer design with closely stacked layers. This design enhances routing density, facilitating the integration of complex circuits for high-frequency applications.

Microvia Integration: The incorporation of microvias, small plated-through holes, enhances interconnect densities and contributes to the overall miniaturization of the PCB. Advanced production processes enable the creation of fine lines and spaces, crucial for intricate circuit patterns.

Adaptability: Ultrathin high-frequency PCBs can be flexibly designed or configured as rigid-flex boards. This adaptability allows them to conform to the specific shape of the device, making them suitable for applications with diverse and complex form factors.

5G Integration: These PCBs play a pivotal role in advancing 5G technology, catering to the demands of high-frequency bands crucial for optimal performance.

Microwave and Millimeter-Wave Devices: Ultrathin high-frequency PCBs find applications in microwave and millimeter-wave devices, including radar systems, satellite communications, and high-frequency test equipment.

The amalgamation of ultrathin structures, advanced materials, high-frequency capabilities, specialized production methods, and adaptability to flexible designs positions these PCBs as marvels in electronic engineering. They effectively meet the evolving requirements of high-frequency applications, pushing the boundaries of electronic design possibilities.

Are There Common Questions about Ultrathin High-Frequency PCBs?

Which materials are commonly utilized in Ultrathin High-Frequency PCBs?

Commonly employed materials include advanced dielectrics and specialized substrates like polytetrafluoroethylene (PTFE). These materials contribute to low signal loss, high thermal stability, and superior high-frequency performance.

What advantages do Ultrathin High-Frequency PCBs provide?

Key advantages encompass compact and lightweight designs, efficient signal transmission at high frequencies, and the ability to meet strict space constraints. These features are particularly valuable in aerospace components and portable electronic devices.

Can Ultrathin High-Frequency PCBs be adapted for flexible designs?

Certainly, Ultrathin High-Frequency PCBs are versatile and can be designed in flexible or rigid-flex configurations. This adaptability makes them suitable for applications requiring flexibility or complex form factors.

In what way do manufacturing technologies enhance Ultrathin High-Frequency PCB performance?

Advanced manufacturing technologies, including microvia technology and precision fabrication processes, play a crucial role in achieving high interconnect densities, fine lines, and spaces for intricate circuit patterns.

Is the Future of Electronics Embracing Ultrathin High-Frequency PCBs?

In the ever-changing field of electronic design, characterized by a continuous quest for innovation, Ultrathin High-Frequency PCBs stand ready to assume a crucial role in driving advancement. The focus on both miniaturization and heightened performance is particularly pronounced in today’s dynamic electronic landscape.Recognized for their slender profiles and outstanding high-frequency capabilities, Ultrathin High-Frequency PCBs emerge as central contributors shaping the next generation of electronic devices.

The evolving requirements for electronic devices, spanning from portable gadgets to aerospace systems, seamlessly align with the strengths of Ultrathin High-Frequency PCBs. Their compact designs not only cater to the shrinking dimensions of modern electronics but also amplify overall system efficiency.

The importance of Ultrathin High-Frequency PCBs becomes prominent in the era of 5G technology. As high-frequency bands become more prevalent, these PCBs are crucial for achieving optimal signal integrity and transmission. They play a pivotal role in the smooth integration of advanced communication systems by minimizing signal loss and ensuring precise control of impedance.

With the electronics industry embracing transformative shifts such as the Internet of Things (IoT) and wearable technology, there is an expected surge in the need for Ultrathin High-Frequency PCBs. The versatility of these PCBs, accommodating both flexible and rigid-flex designs, creates opportunities for innovative form factors, enabling electronic devices to adapt to a wide range of shapes and sizes.This flexibility positions Ultrathin High-Frequency PCBs as crucial elements in addressing the evolving requirements of electronic design during the IoT and wearable device era.

In summary, the upcoming phase of electronics is intricately linked to the widespread adoption of Ultrathin High-Frequency PCBs. Their unique fusion of slender profiles and outstanding high-frequency capabilities effortlessly meets the demands of future electronic devices. As technology continues to advance, these PCBs stand ready to play a pivotal role in propelling progress, offering significant contributions to the ongoing evolution of electronic design and manufacturing.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier