Top 10 Package Substrate Manufacturer

Top 10 Package Substrate Manufacturer,The Top 10 Package Substrate list comprises cutting-edge substrates recognized for their innovation and impact in semiconductor packaging. These substrates excel in various aspects, including high-density interconnections, efficient thermal management, and reliability. They support diverse applications across industries such as telecommunications, automotive, and consumer electronics. Key features include advanced materials, precise manufacturing processes, and optimized designs for performance and miniaturization. The Top 10 Package Substrates drive advancements in semiconductor packaging, enabling the development of smaller, faster, and more reliable electronic devices to meet the demands of modern technology.

Absolutely, let’s take a different approach:

Imagine the “Top 10 Package Substrate” as a playlist of the coolest materials in the world of semiconductor packaging. Each material has its own vibe and role in the electronics scene. Check it out:

FR-4: The Classic Groove – It’s like the evergreen rockstar, a glass-reinforced epoxy resin that you find rocking out in almost every multilayer circuit board.

High-Speed Laminate: The Sonic Speedster – When your signals need to break the sound barrier, these substrates step up to make sure your data stays in the fast lane.

Flex PCBs: The Dancefloor Darlings – For those circuits that need to move and groove, flex PCBs are the flexible dancers, ready to bend and flex as the music changes.

Rigid-Flex PCBs: The Fusion Maestros – Imagine a band that seamlessly blends rock and jazz. That’s what these substrates do – rigid when you need structure, flexible when you need versatility.

Metal Core PCBs: The Cool Cats of Heat – They handle heat like it’s a breeze, perfect for the hotspots in electronics, like LED setups and power electronics.

Ceramic Substrates: The Heat Defenders – These substrates are like the knights in shining armor for high-temperature, high-frequency, and high-power quests.

BT Epoxy: The Heat-Resistant Hero – Joining the party with resistance to high temperatures, BT Epoxy is the go-to for high-performance packaging.

PPO (Polyphenylene Oxide): The Steady Eddies – Stability and low distortion are their trademarks, perfect for applications that demand a steady hand.

Teflon (PTFE): The Microwavable Marvel – If your project involves high frequencies or microwaves, Teflon is the superhero with low loss and top-notch insulation.

Rogers: The VIPs of Wireless Wonderland – Straight from Rogers Corporation, these substrates are like the VIPs in the world of wireless communication and high-frequency electronics.

Choosing the right material is like curating the perfect playlist for your project. Whether it’s speed, flexibility, or heat resistance, each material brings its own unique flavor to the PCB design party!

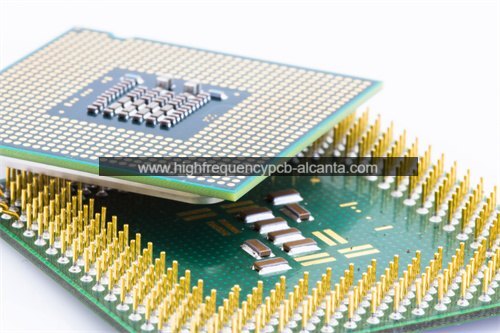

Top 10 package Substrate Manufacturer

What is the Function of Top 10 Package Substrate?

Consider the “Top 10 Package Substrate” as the unsung MVPs (Most Valuable Players) in the realm of electronic devices. These substrates are like versatile team players, taking on various roles to ensure the flawless operation of your gadgets:

Structural Cornerstones: Picture substrates as the unsung heroes forming the structural backbone, providing a robust foundation for electronic components like chips, resistors, and capacitors.

Electric Information Highways: Acting as information highways, substrates create efficient pathways that allow the smooth flow of electrical signals between different components within an integrated circuit.

Signal Guardians: In high-speed scenarios, these substrates play the role of vigilant guardians, safeguarding signal integrity and preventing any unwanted disturbances or noise.

Heat Management Pros: Some substrates, like Metal Core PCBs and Ceramic Substrates, are the pros in managing heat, preventing devices from overheating and ensuring a cool performance.

Reliable Support System: Beyond mere connections, substrates act as a reliable support system, ensuring electronic components stay securely in place, resilient against vibrations or mechanical stresses.

Flexibility Champions: Enter the flexibility champions – flexible and rigid-flex PCB substrates, allowing the circuit board to flex and adapt, adding a touch of flexibility to electronic designs.

Dielectric Maestros: Substrates with unique dielectric properties, such as Teflon (PTFE), master the art of insulation, minimizing signal loss and proving ideal for high-frequency and microwave applications.

Tailored Design Elements: The choice of substrate is like selecting tailored design elements, customizing solutions to meet the specific demands of the electronic device or circuit.

Manufacturing Allies: Substrates are trusted allies in the manufacturing process, seamlessly integrating with procedures like soldering, assembly, and testing.

Application Specialists: Each substrate serves as a specialist in its own right. Take Rogers substrates, for instance – specialists in the field of wireless communication, thanks to their exceptional high-frequency performance.

In essence, the Top 10 Package Substrates are the MVPs working behind the scenes, adapting and playing different roles to ensure the stellar performance of electronic devices, just like a winning team on the field.

What Are the Different Types of Top 10 Package Substrate?

Certainly! Let’s explore a diverse range of substrate types often considered in the realm of semiconductor packaging, each playing a distinctive role in the electronic symphony:

Versatile FR-4 (Flame Retardant 4): Think of it as the workhorse, a glass-reinforced epoxy substrate commonly found in multilayer PCBs, bringing reliability to various applications.

High-Speed Laminate Heroes: These substrates are the superheroes of high-frequency applications, ensuring signal integrity at lightning speeds, essential for data transmission in the fast lane.

Flex PCB Mavericks: Imagine substrates that can groove and sway – flexible PCBs designed to bend and flex, perfect for applications demanding adaptability and space efficiency.

Rigid-Flex Virtuosos: The fusion artists of the substrate world, combining the best of rigid and flexible substrates to handle the complexities of intricate electronic designs.

Metal Core PCB Maestros: With a metal core, typically aluminum or copper, these substrates conduct not just electricity but also excel in dissipating heat, making them stars in LED and power electronics.

Ceramic Wizards: Crafted from ceramics, these substrates boast high thermal conductivity, ideal for applications where temperatures, frequencies, and power levels reach challenging heights.

BT Epoxy Trailblazers: Known for their ability to handle high temperatures, BT epoxy substrates carve a path in high-performance packaging, navigating the heat with finesse.

PPO Precision Players: PPO-based substrates enter the stage with stability and low distortion, bringing precision to applications that demand a steady hand.

Teflon (PTFE) Pioneers: The pioneers in low loss and insulation, PTFE substrates take the lead in high-frequency and microwave applications, minimizing signal loss with expertise.

Rogers Innovators: Hailing from Rogers Corporation, these substrates are the innovators, often chosen for their outstanding electrical properties, making them key players in wireless communication and high-frequency realms.

In essence, the diverse array of substrate types caters to the unique needs of electronic designs, each bringing its own flair and capabilities to the electronic orchestra. The selection of a substrate becomes a nuanced decision, akin to assembling a skilled ensemble for a symphony of electronic performance.

What is the Relationship Between Top 10 Package Substrate and IC Packaging?

Imagine the partnership between the “Top 10 Package Substrate” and IC packaging as a choreography in the intricate dance of semiconductor technology. The package substrate takes on the role of a backstage maestro, orchestrating key elements for the flawless performance of the star attraction – the Integrated Circuit (IC) chip.

Foundation Craftsmanship: Much like the set designer builds a sturdy stage, the package substrate provides an unwavering foundation for the IC chip. It’s the unseen architect ensuring the chip stands firmly on the electronic stage.

Connective Choreography: Think of the substrate as a skilled choreographer, coordinating the dance of electrons. Its conductive pathways weave a complex routine, connecting the intricate moves of the IC chip with the external world, ensuring a seamless performance.

Cooling Choreographer: In certain acts that demand cool composure, the package substrate steps into the role of a cooling choreographer. Materials like metal core PCBs or ceramics become the cool breeze, preventing the IC from breaking into a technological sweat.

Signal Symphony Conductor: The package substrate transforms into a symphony conductor, directing the flow of electrical signals with precision. In the realm of high-speed and high-frequency performances, it ensures that the signal harmony remains pitch-perfect.

In the grand theater of semiconductor technology, the package substrate is not merely a backdrop; it’s a backstage virtuoso, meticulously arranging the elements for the IC’s spotlight moment. The selection of substrate materials and design becomes an art of crafting the perfect stage – a stage where the IC can shine in its electronic performance.

How Does Top 10 Package Substrate Differ from Regular PCBs?

Let’s embark on a journey through the realms of substrate diversity, comparing what is colloquially termed “Top 10 Package Substrate” with the steadfast regular Printed Circuit Boards (PCBs). In this exploration, we’ll delve into their unique attributes, considering material composition, performance nuances, application specialization, cost dynamics, manufacturing intricacies, and the dance of flexibility:

Material Symphony:

Top 10 Package Substrate: Picture a palette of refined materials – advanced laminates, ceramics, and even metal cores like aluminum or copper, each chosen for its specialized prowess.

Regular PCBs: Enter the reliable FR-4, the unsung hero of commonality, a glass-reinforced epoxy laminate standing strong in the world of circuitry.

Performance Ballet:

Top 10 Package Substrate: Crafted for the spotlight – tailored for high-frequency communication, power-intensive performances, and scenarios where thermal control takes center stage.

Regular PCBs: The versatile workhorse, adept at supporting a myriad of electronic applications without the need for extravagant features.

Application Choreography:

Top 10 Package Substrate: Handpicked for specific roles – the leading actors in wireless communication, the maestros of high-speed data transmission.

Regular PCBs: The ensemble cast, found in everyday devices without the need for grandiose specifications.

Cost Waltz:

Top 10 Package Substrate: Quality comes at a price – the use of specialized materials and intricate manufacturing processes often raises the curtain on a higher cost.

Regular PCBs: Wallet-friendly performers, accessible to a broad audience and fitting seamlessly into projects with modest requirements.

Manufacturing Ballet:

Top 10 Package Substrate: These substrates demand a dedicated stage – specialized processes and facilities are part of their backstage magic.

Regular PCBs: The familiar faces on the production floor, gracefully navigating standard processes to meet the demands of everyday electronics.

Flexibility Waltz:

Top 10 Package Substrate: The flexible virtuosos – offering options for both flexibility and rigidity, adapting to the twists and turns of electronic narratives.

Regular PCBs: Sturdy and adaptable, dancing to various form factors but without the extravagant twists of their flexible counterparts.

In the grand theater of electronics, each substrate type takes on a unique role, from the specialized performances of the “Top 10 Package Substrate” to the versatile acts of regular PCBs. The script dictates the choice, and the stage is set for electronic performances of all kinds.

What are the Main Structures and Production Technologies of Top 10 Package Substrate?

Let’s embark on a captivating exploration of high-performance substrates, where each type unveils its distinct blend of materials and manufacturing techniques, enriching the vibrant tapestry of advanced semiconductor packaging:

High-Speed Laminates:

Architectural Harmony: Layers thoughtfully orchestrated to embrace precise dielectric constants, crafting a symphony that propels high-speed signals with finesse.

Production Choreography: A meticulous manufacturing ballet unfolds, featuring the precision of layer alignment, the artistry of high-resolution imaging, and the rigorous testing of controlled impedance.

Ceramic Substrates:

Ceramic Elegance: Crafted from the graceful alumina, these substrates channel heat with poise.

Production Artistry: An artistic journey unfolds, weaving through tape casting, green machining, and the transformative firing process within a carefully orchestrated atmosphere.

Metal Core PCBs (MCPCBs):

Core Brilliance: Boasting a resilient metal core, whether it’s the versatile aluminum or the conductive copper, adding a touch of thermal brilliance.

Production Rhythm: A rhythmic dance of thermal clad lamination, drilling, and etching ensues, carving a circuit with precision.

Rogers Substrates:

Wireless Sonata: Laminates tuned for the eloquence of high-frequency performances, gracefully dancing within the realms of wireless communication.

Precision Ensemble: A symphony unfolds, involving controlled impedance testing and the nuanced artistry of laser drilling for vias.

Flex PCBs (Flexible Printed Circuit Boards):

Flexibility Flourish: Composed of materials like the resilient polyimide, enabling an electronic dance of bends and twists.

Roll-to-Roll Rhapsody: A graceful roll-to-roll manufacturing waltz ensues, complemented by the precision of laser cutting and the harmonious assembly of flexible circuits.

Rigid-Flex PCBs (Rigid-Flexible Printed Circuit Boards):

Versatile Fusion: A composition that seamlessly blends the rigidity of tradition with the flexibility of the avant-garde.

Specialized Symphony: An orchestra of specialized manufacturing processes unfolds, featuring the delicate lamination of rigid and flexible layers and the precise notes of laser processing.

BT Epoxy (Bismaleimide Triazine Epoxy) Substrates:

Thermal Poise: Harnessing the resilience of BT epoxy for its remarkable resistance to high temperatures.

Production Alchemy: A magical alchemy takes center stage, involving resin impregnation, layer stacking, and the controlled curing of materials.

PPO (Polyphenylene Oxide) Substrates:

Stability Sonata: Utilizing PPO-based materials for their stability, steering clear of the dissonance of distortion.

Precision Craftsmanship: Precision manufacturing unfolds, akin to crafting a delicate masterpiece, maintaining the integrity and stability of the material.

Teflon (PTFE – Polytetrafluoroethylene) Substrates:

Insulation Poetry: Embracing the insulating poetry of PTFE, celebrated for its low loss and electrical insulation properties.

Specialized Handling: Specialized processes unveil, involving the lyrical dance of chemical etching and the artful grace of controlled lamination harmonizing with PTFE.

High-Frequency LCP (Liquid Crystal Polymer) Substrates:

Frequency Flourish: Elevated by LCP, these substrates reach the zenith of high-frequency performance.

Craftsmanship Mastery: Specialized production processes unfold, featuring the artful mastery of injection molding and the precision dance of laser processing.

In this symphony of substrates, each type takes center stage, contributing its own melody to the intricate composition of advanced semiconductor packaging.

Frequently Asked Questions (FAQs)

What is the “Top 10 Package Substrate”?

The “Top 10 Package Substrate” refers to a distinguished lineup of high-performance substrates often recognized for their excellence in advanced semiconductor packaging.

How Are These Substrates Selected?

The selection process involves considering materials with superior electrical, thermal, and mechanical properties, placing them in the elite league of high-performance substrates.

What Sets Top 10 Substrates Apart?

These substrates stand out due to their exceptional characteristics, tailored for applications demanding top-notch performance, such as high-speed data transmission or thermal management.

Where Can I Encounter Top 10 Substrates?

These substrates make appearances in cutting-edge electronic designs, particularly in applications like wireless communication, high-frequency scenarios, or power electronics.

Are Top 10 Substrates Costlier?

Quality often comes at a price. The use of specialized materials and manufacturing processes can contribute to a higher cost compared to conventional substrates.

Can Regular PCBs Be Upgraded to Top 10 Substrates?

While possible, it’s not a simple swap. Upgrading may involve redesigning the circuitry and accommodating the specific requirements of high-performance substrates.

Do Top 10 Substrates Require Specialized Manufacturing?

Yes, they do. The production journey involves advanced processes, precision manufacturing, and often requires specialized facilities to ensure the substrates meet stringent standards.

Are Flexibility and Rigidity Both Present in Top 10 Substrates?

Indeed! Some top substrates offer flexibility options, adapting to the narrative of the electronic design, while others may maintain a rigid composure, depending on the application.

How Do Top 10 Substrates Contribute to Signal Integrity?

These substrates are crafted to be virtuosos in maintaining signal integrity. Their material composition and design are tailored to minimize signal loss and distortion, especially in high-frequency applications.

Can I Use Top 10 Substrates for Everyday Electronics?

While these substrates shine in specialized applications, they may be overqualified for everyday electronics. Regular PCBs are often more cost-effective and suitable for common electronic needs.

Conclusion

To encapsulate, the journey through the realm of “Top 10 Package Substrate” beckons us into the intricate tapestry of high-performance materials in semiconductor packaging. This handpicked selection of substrates, celebrated for their extraordinary attributes, caters to the intricacies of cutting-edge electronic applications.

Inquisitive exploration into the fundamentals of these substrates unravels a narrative rich in precision engineering, innovative materials, and multifaceted applications. From their distinct material compositions to their pivotal roles in high-speed communication, thermal regulation, and signal integrity, these substrates emerge as linchpins in shaping the trajectory of electronic design.

As we traverse the landscape of “Top 10 Package Substrate,” we delve into the craftsmanship behind their curation, the ingenuity embedded in their manufacturing intricacies, and the nuanced considerations essential for their deployment. While these substrates bring unparalleled capabilities to specialized contexts, it’s imperative to acknowledge their unique contributions and potential higher costs in comparison to regular PCBs.

This exploration transcends mere question-and-answer dynamics; it invites us into a journey of discovery where each query unfurls layers of insights about these premier substrates. Whether encountering them in the realms of wireless communication, high-speed data transmission, or power electronics, the “Top 10 Package Substrate” lineup underscores versatility and prowess.

In the grand symphony of electronics, these substrates serenade a distinctive melody, harmonizing seamlessly with intricate electronic designs. As technology evolves, so does the landscape of high-performance substrates, urging us to remain inquisitive, adaptable, and engaged in the perpetual evolution of electronic innovation.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier