SHDBU Substrates Manufacturer

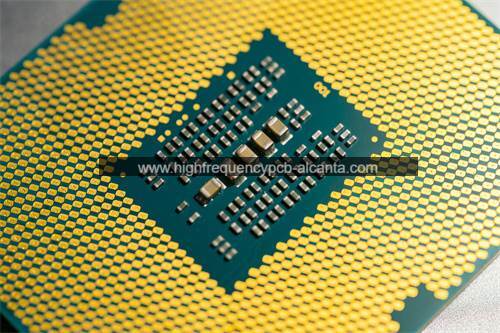

SHDBU Substrates Manufacturer,SHDBU (Super High Density Build Up) Substrates are advanced circuit boards designed for high-density electronic packaging. These substrates feature multiple layers of thin films and advanced manufacturing techniques to accommodate complex circuitry in a compact space. SHDBU Substrates offer superior electrical performance, reliability, and thermal management. With ultra-thin traces and dense vias, they support miniaturization while maintaining signal integrity. These substrates are crucial for high-performance applications in telecommunications, computing, and automotive industries, where space optimization and reliability are paramount. SHDBU Substrates drive innovation in electronic packaging, enabling the development of smaller, more powerful, and efficient electronic devices.

Substrate packages, also known as packaging substrates, serve as vital elements within semiconductor packaging procedures. including integrated circuits (ICs).microprocessors, and memory chips. Here are their primary roles:

Package substrates feature conductive pathways and through-holes, enabling seamless electrical connections between the chip’s internal circuitry and external pins or balls. This promotes efficient integration with external electronic systems, thereby enhancing overall performance.

Package substrates are specifically designed to efficiently dissipate heat, effectively maintaining optimal temperatures for semiconductor devices during operation. This critical function prevents the occurrence of overheating, thereby guaranteeing consistent performance and reliability over time.

Package substrates are specifically designed to efficiently dissipate heat, effectively maintaining optimal temperatures for semiconductor devices during operation. This critical function prevents the occurrence of overheating, thereby guaranteeing consistent performance and reliability over time.

Tailoring package substrates to suit particular application needs enables the creation of more streamlined and efficient electronic devices. This flexibility in design and sizing plays a crucial role in enhancing compactness and optimizing device performance.

Package substrates are crucial elements in semiconductor packaging, enabling the smooth integration and dependable functioning of semiconductor devices in electronic systems. The choice of material depends on factors such as cost-effectiveness, performance requirements, and environmental considerations.

SHDBU Substrates Manufacturer

What is the function of SHDBU Package Substrates?

SHDBU (Super High Density Build-Up) package substrates are vital elements in contemporary semiconductor packaging, serving a variety of essential functions:

Increased Interconnect Density: SHDBU substrates excel in accommodating a dense network of interconnects, allowing multiple semiconductor devices and components to be connected within a limited space. This capability enables the creation of compact electronic packages with enhanced functionality.

Facilitating Miniaturization: SHDBU substrates play a key role in driving the ongoing trend of miniaturization in electronic devices by accommodating a higher density of interconnects and routing channels. This is especially advantageous in applications where optimizing space is paramount, such as in mobile devices and wearables.

Preservation of Signal Integrity: SHDBU substrates are engineered to maintain signal integrity by minimizing signal loss and reducing interference, such as crosstalk. This ensures reliable communication between semiconductor devices, enhancing overall system performance.

Efficient Thermal Management: Despite their high-density design, SHDBU substrates efficiently dissipate heat generated by semiconductor devices during operation. This effective thermal management helps regulate operating temperatures, ensuring the reliability and longevity of electronic packages.

Integration of Advanced Technologies: SHDBU substrates facilitate the integration of advanced technologies, including embedded passive components and high-speed signal routing. They also support innovative packaging techniques like system-in-package (SiP) and fan-out wafer-level packaging (FOWLP), enabling the development of highly integrated electronic systems.

In summary, SHDBU package substrates are essential for meeting the demanding requirements of modern semiconductor packaging. They provide high-density interconnects, support miniaturization, preserve signal integrity, manage heat effectively, and enable the integration of advanced technologies.

What are the different types of SHDBU Package Substrates?

SHDBU (Super High Density Build-Up) package substrates are available in diverse types, each crafted to suit distinct application requirements:

Standard SHDBU Substrates: These substrates boast a high-density build-up structure, housing multiple layers of interconnects to enable efficient signal and power routing within a compact framework.

Embedded Passive SHDBU Substrates: This variant integrates passive components like resistors, capacitors, and inductors directly into the substrate material. Such integration conserves space, diminishes parasitic effects, and heightens overall system performance.

High-Speed SHDBU Substrates: Engineered for applications necessitating high-speed signal transmission, these substrates employ advanced materials and design methodologies to curtail signal loss and uphold signal integrity, especially at elevated frequencies.

RF/Microwave SHDBU Substrates: Optimized for utilization in radio frequency (RF) and microwave applications, these substrates leverage specialized materials and geometries to achieve minimal signal loss, high isolation, and low impedance mismatch, vital for RF and microwave circuits.

Flexible SHDBU Substrates: Fabricated using flexible materials like polyimide or liquid crystal polymer (LCP), these substrates possess the capability to bend or flex. They are well-suited for applications requiring flexibility or conformability, such as wearable electronics or bendable displays.

Advanced Packaging SHDBU Substrates: These substrates leverage cutting-edge packaging techniques such as system-in-package (SiP) or fan-out wafer-level packaging (FOWLP). This facilitates the integration of multiple semiconductor devices and components within a single package, augmenting system integration and performance.

Each variant of SHDBU package substrate presents distinct attributes and merits tailored to specific application requisites. These span from conventional interconnect density to specialized functionalities like high-speed transmission or flexibility.

How do SHDBU Package Substrates differ from PCBs?

SHDBU Package Substrates differ from PCBs in several key aspects:

Functionality:

SHDBU substrates primarily serve as platforms for mounting semiconductor chips, enabling electrical connections and signal transmission between the chip and the package.

PCBs, on the other hand, act as the structural and electrical foundation for various electronic components, facilitating connections between them and supporting overall circuit functionality.

Design Complexity:

SHDBU substrates are intricately designed to accommodate densely packed semiconductor chips and advanced packaging techniques like SiP and FOWLP, emphasizing high-density interconnects and optimized signal paths.

PCBs have a broader design scope, considering factors such as component placement, signal routing, thermal management, and mechanical support across different layers and sections of the board.

Materials and Manufacturing:

SHDBU substrates utilize specialized materials like high-performance laminates and metal layers, tailored for high-speed signal transmission and thermal dissipation.

PCBs can be made from various materials such as FR-4, flexible substrates, and metal core boards, with manufacturing processes like etching, drilling, and soldering.

Integration and Packaging Techniques:

SHDBU substrates are often integrated into advanced packaging methods, allowing for the consolidation of multiple chips and components within a single package.

PCBs are commonly used in traditional packaging approaches like SMT and THT, where individual components are mounted and soldered onto the board.

Applications:

SHDBU substrates find applications in high-performance electronic systems such as mobile devices, automotive electronics, and high-speed communication systems.

PCBs are employed in a wide array of electronic devices and industries, spanning consumer electronics, industrial equipment, medical devices, and aerospace technology.

In essence, while both SHDBU substrates and PCBs are vital in electronics, they serve distinct roles, employ different design strategies, and cater to diverse applications within the field.

What are the main structure and production technologies of SHDBU Package Substrates?

SHDBU Package Substrates are characterized by their multilayered structure and utilize advanced production technologies for high-density interconnections. Here’s a breakdown of their main structure and manufacturing processes:

Base Material Choice:

SHDBU substrates begin with a base material, often a high-performance laminate like BT resin or PTFE, renowned for their electrical properties and thermal stability.

Layer Build-Up:

The substrate undergoes a build-up process to create multiple layers of interconnects and routing channels. This involves depositing dielectric layers and then patterning and metallizing them.

Conductive Path Formation:

Sophisticated lithography techniques, such as photolithography or laser ablation, define conductive patterns on the substrate layers. These patterns establish the electrical pathways connecting semiconductor chips to external components.

Via Creation:

Vias are essential for establishing vertical connections between different substrate layers. Various methods like laser drilling or chemical etching are employed for via formation.

Metallization:

Conductive materials, typically copper, are deposited onto the substrate surface and within the vias. This ensures electrical conductivity and reliable signal transmission.

Surface Treatment:

Surface finishing techniques, like electroplating, enhance solderability and corrosion resistance of the substrate’s external surfaces, facilitating smooth assembly and durability.

Quality Assurance:

Stringent quality control measures are implemented throughout production. This includes inspections for defects, dimensional accuracy, and electrical integrity, ensuring reliable performance in diverse operating conditions.

In essence, SHDBU Package Substrates employ advanced manufacturing processes to achieve intricate interconnects and robust performance, making them vital components in modern electronic packaging.

Frequently Asked Questions (FAQs)

What does SHDBU stand for?

SHDBU stands for Substrate High Density Build-Up.

What are SHDBU Package Substrates used for?

SHDBU Package Substrates are used as carriers for semiconductor chips in advanced packaging technologies. They facilitate electrical connections and signal transmission between the chip and the package.

What production technologies are involved in manufacturing SHDBU Package Substrates?

Production technologies include sequential build-up (SBU) or semi-additive processes (SAP) for layer build-up, advanced lithography for conductive pattern formation, via formation techniques like laser drilling or chemical etching, metallization processes, and surface finishing techniques.

What applications are SHDBU Package Substrates suitable for?

SHDBU Package Substrates find applications in various high-performance electronic systems such as mobile devices, automotive electronics, high-speed communication systems, and advanced computing devices.

How do SHDBU Package Substrates differ from traditional PCBs?

SHDBU Package Substrates differ from traditional PCBs in terms of their design complexity, materials used, manufacturing processes, and intended applications. While PCBs serve as the backbone for electronic devices, SHDBU substrates focus on high-density interconnects and optimized signal transmission for semiconductor chips in advanced packaging technologies.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier