What is Rogers RT/duroid 6002 PCBs?

Rogers RT/duroid 6002 PCB Supplier,Rogers RT/duroid 6002 PCB is a high-performance laminate material designed for demanding RF and microwave applications. With a low dielectric constant and loss tangent, it ensures minimal signal loss and superior signal integrity. This substrate offers excellent dimensional stability and thermal conductivity, making it ideal for high-power and high-frequency circuits. Rogers RT/duroid 6002 PCB is widely used in aerospace, defense, and telecommunications industries, where reliability and performance are critical. Its advanced material composition and precise manufacturing processes enable the development of compact, high-density electronic assemblies with enhanced efficiency and durability in challenging environments.

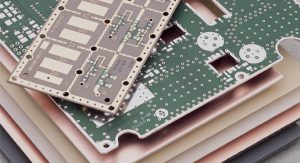

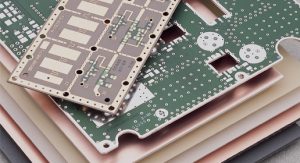

RT/duroid 6002 laminates are low loss materials that provide excellent high frequency performance. With excellent mechanical and electrical properties, these materials are reliable for use in multi-layer board constructions.

Features

- Dielectric constant (Dk) of 2.94 +/- .04

- Low thermal coefficient of Dk at 12 ppm/°C

- Dissipation factor of .0012 at 10GHz

- Low Z-axis coefficient of thermal expansion at 24 ppm/°C

Benefits

- Low loss for excellent high frequency performance

- Tight thickness control

- In-plane expansion coefficient matched to copper

- Low out-gassing; Ideal for space applications

- Excellent dimensional stability

Rogers RT/duroid 6002 is a type of high-frequency circuit board material primarily used for radio frequency (RF) and microwave applications. This material is manufactured by Rogers Corporation and is designed to provide excellent performance and stability in the high-frequency range.

RT/duroid 6002 PCBs are commonly used in electronic devices that operate at higher frequencies, such as radar systems, communication equipment, antenna systems, and other microwave circuits. Some key characteristics of this material include low loss, low leakage, stable dielectric constant, and good mechanical performance.

The features of Rogers RT/duroid 6002 PCBs also include reliability in high-temperature and high-humidity environments, as well as resistance to corrosion from chemical substances. This makes it an ideal choice for many RF and microwave applications with high-performance and stability requirements.

Rogers RT/duroid 6002 PCB Supplier

How Do Rogers RT/duroid 6002 PCBs Function?

Rogers RT/duroid 6002 is a high-performance material used in electronic printed circuit boards (PCBs), primarily for radio frequency (RF) and microwave applications. Manufactured by Rogers Corporation, it boasts superior electrical properties, making it suitable for demanding high-frequency applications such as communication and radar systems.

Here are some key features and functions of Rogers RT/duroid 6002 PCB:

Low Loss: RT/duroid 6002 exhibits low loss characteristics, reducing signal attenuation at high frequencies and helping to maintain signal clarity and strength.

High Dielectric Constant: The material’s high dielectric constant enables high signal propagation speed in the microwave frequency range, contributing to improved system performance.

Stable Dielectric Constant: RT/duroid 6002 maintains a relatively stable dielectric constant over a wide frequency band, crucial for preserving signal phase stability.

Superior Mechanical Performance: PCB materials need to have sufficient mechanical strength and stability to adapt to various environmental conditions, and RT/duroid 6002 excels in this regard.

High-Temperature Performance: The material is engineered to endure elevated temperatures, a critical factor for certain high-power applications.

RF and Microwave Applications: Thanks to its outstanding electrical characteristics, RT/duroid 6002 finds extensive application in crafting RF and microwave circuits. Its uses span antennas, power dividers, couplers, filters, and various other components in these high-frequency designs.

Excellent Chemical Stability: The material exhibits strong resistance to chemical substances, contributing to its reliability in diverse environmental conditions.

In summary, Rogers RT/duroid 6002 PCB is an advanced material designed for high-frequency applications, ensuring excellent performance and reliability in RF and microwave systems.

| Property | Typical Value RT/duroid 6002 | Direction | Units [1] | Conditions | Test Method |

| Dielectric Constant, εr

Process |

2.94 ± 0.04 | Z | – | 10GHz/23°C | IPC-TM-650, 2.5.5.5 |

| Dielectric Constant, εr

Design |

2.94 | 8GHz-40GHz | Differential Phase Length

Method |

||

| Dissipation Factor, TAN δ | 0.0012 | Z | – | 10 GHz/23°C | IPC-TM-650, 2.5.5.5 |

| Thermal Coefficient of εr | +12 | Z | ppm/°C | 10 GHz

0-100°C |

IPC-TM-650, 2.5.5.5 |

| Volume Resistivity | 10⁶ | Z | Mohm cm | A | ASTM D257 |

| Surface Resistivity | 10⁷ | Z | Mohm | A | ASTM D257 |

| Tensile Modulus | 828 (120) | X,Y | MPa (kpsi) | 23°C | ASTM D638 |

| Ultimate Stress | 6.9 (1.0) | X,Y | MPa (kpsi) | ||

| Ultimate Strain | 7.3 | X,Y | % | ||

| Compressive

Modulus |

2482 (360) | Z | MPa (kpsi) | ASTM D638 | |

| Moisture Absorption | 0.02 | – | % | D48/50 | IPC-TM-650, 2.6.2.1

ASTM D570 |

| Thermal Conductivity | 0.60 | – | W/m/K | 80°C | ASTM C518 |

| Coefficient of

Thermal Expansion (-55 to 288 °C) |

16

16 24 |

X

Y Z |

ppm/°C | 23°C/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | °C TGA | ASTM D3850 | ||

| Density | 2.1 | gm/cm3 | ASTM D792 | ||

| Specific Heat | 0.93 (0.22) | – | J/g/K (BTU/lb/°F) | – | Calculated |

| Copper Peel | 8.9 (1.6) | lbs/in (N/mm) | IPC-TM-650 2.4.8 | ||

| Flammability | V-O | UL94 | |||

| Lead-Free Process Compatible | YES |

Which Types of Rogers RT/duroid 6002 PCBs?

There are different types of Rogers RT/duroid 6002 PCBs, primarily distinguished based on their thickness and other specific requirements. Here are some possible types:

RT/duroid 6002 Standard Thickness: This is the standard thickness of RT/duroid 6002, typically chosen based on the specific requirements of the application.

RT/duroid 6002 Special Thickness: In addition to the standard thickness, there may be options for special thicknesses to meet the requirements of specific designs.

RT/duroid 6002 with Copper Foil Cladding: Some RT/duroid 6002 PCBs may come with copper foil cladding to provide enhanced conductivity.

RT/duroid 6002 with Different Surface Finishes: PCBs may have different surface finishes, such as gold plating or other coatings, to meet the specific needs of applications.

RT/duroid 6002 with Special Adhesive Systems: Certain types of RT/duroid 6002 may include special adhesive systems to accommodate different lamination and bonding requirements.

This categorization is a broad overview, and practical variations may exist, contingent upon the precise needs of applications. For comprehensive details, it is advisable to consult the official documentation provided by Rogers Corporation or engage with their engineering team.

How Do Rogers RT/duroid 6002 PCBs Compare to Traditional PCBs?

Rogers RT/duroid 6002 PCBs exhibit several notable differences and advantages compared to traditional PCBs:

High-Frequency Applications: Rogers RT/duroid 6002 is primarily designed for high-frequency RF and microwave applications, where traditional PCBs may perform less effectively. RT/duroid 6002 demonstrates superior electrical performance in high-frequency environments.

Low Loss: RT/duroid 6002 features low-loss characteristics, contributing to reduced signal attenuation at high frequencies. In contrast, traditional PCBs may experience higher signal loss at elevated frequencies.

High Dielectric Constant and Relative Stability: RT/duroid 6002 possesses a higher dielectric constant and maintains relative stability over a wide frequency band. The dielectric constant of traditional PCBs may be lower or less stable.

Mechanical Performance: RT/duroid 6002 excels in mechanical strength and stability, making it suitable for applications with stringent mechanical requirements. Traditional PCBs may exhibit inferior mechanical performance.

High-Temperature Performance: Designed to withstand high-temperature environments, RT/duroid 6002 offers greater reliability in high-temperature applications. Traditional PCBs may perform less effectively under elevated temperatures.

In summary, Rogers RT/duroid 6002 PCBs are more suitable for high-frequency, high-performance applications with stringent electrical requirements compared to traditional PCBs. However, the choice between the two depends on specific application needs and cost considerations.

What Sets Rogers RT/duroid 6002 PCBs Apart?

Rogers RT/duroid 6002 PCBs stand out in several aspects:

High-Frequency Performance: RT/duroid 6002 is renowned for its excellent performance in the high-frequency range.It is recognized for its minimal signal loss, low electrical leakage, and a consistent dielectric constant, rendering it well-suited for applications in radio frequency (RF) and microwave technologies.

Stability: The material demonstrates exceptional stability, even under conditions of elevated temperature and humidity. This makes RT/duroid 6002 PCBs suitable for various complex applications, such as radar systems and communication devices.

Mechanical Performance: In addition to excellent electrical properties, RT/duroid 6002 PCBs demonstrate good mechanical performance. This makes them suitable for applications with high requirements for board strength and stability.

Chemical Stability: The material shows good resistance to corrosion from chemical substances, enhancing its reliability in various environmental conditions.

Customizability: RT/duroid 6002 PCBs offer customization options such as different thicknesses, coatings, and adhesive systems to meet specific design requirements.

Overall, Rogers RT/duroid 6002 PCBs find widespread use in RF and microwave applications due to their outstanding performance in high-frequency, stability, and mechanical aspects. For in-depth information on their specific uses and technical specifications, it is recommended to consult the official documentation from Rogers Corporation or engage with their engineering team.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings |

| 0.010” (0.252mm) +/- 0.0007”

0.020” (0.508mm) +/- 0.0010” 0.030” (0.762mm) +/- 0.0010” 0.060” (1.524mm) +/- 0.0020”*Additional non-standard thicknesses available 0.005” – 0.250” in increments of 0.005” |

18” X 12” (457mm X 305mm)

18” X 24” (457mm X 610mm)*Additional panel sizes available |

Electrodeposited Copper Foil

½ oz. (18µm) HH/HH 1 oz. (35µm) H1/H1Rolled Copper Foil ½ oz. (18µm) AH/AH 1 oz. (35µm) A1/A1*Additional claddings, such as heavy metal, resistive foil and unclad are available |

What Constitutes the Structure and Production Technologies of Rogers RT/duroid 6002 PCBs?

The structure and production technologies of Rogers RT/duroid 6002 PCBs include several aspects:

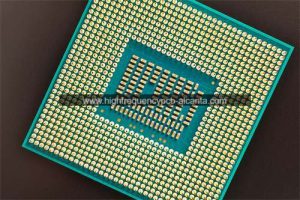

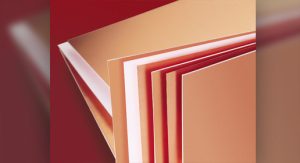

Basic Structure: RT/duroid 6002 typically consists of a substrate made of glass fiber-reinforced polytetrafluoroethylene (PTFE). This type of substrate performs exceptionally well in high-frequency applications. PTFE provides low loss and stable dielectric properties, while the glass fiber reinforcement enhances the material’s mechanical strength.

Conductive Layers: The conductive layers of the PCB usually employ copper foil to ensure good conductivity. These conductive layers can be stacked in multiple layers based on design requirements.

Special Coatings: To meet specific application requirements, RT/duroid 6002 PCBs may undergo special coating treatments, such as corrosion-resistant layers or metal coatings, to provide additional performance or protection.

Adhesive Systems: The production of RT/duroid 6002 PCBs may involve the use of special adhesive systems to ensure strong bonding between layers and to provide the required electrical performance.

Manufacturing Processes: The PCB manufacturing process commonly involves lamination, wherein different material layers are securely bonded at elevated temperatures and pressures. This combination relies on both chemical reactions and physical pressure to guarantee the board’s comprehensive performance and reliability.

The structure and production methods can vary depending on the manufacturing processes adopted by the specific manufacturer. For detailed information on RT/duroid 6002 PCBs, it is recommended to refer to the official documentation from Rogers Corporation or contact their engineering team.

FAQs about Rogers RT/duroid 6002 PCBs: What Do Engineers Need to Know?

What is Rogers RT/duroid 6002 PCB?

Rogers RT/duroid 6002 PCB is a high-performance electronic printed circuit board (PCB) material specifically designed for radio frequency (RF) and microwave applications. Manufactured by Rogers Corporation, it boasts superior electrical properties.

How does RT/duroid 6002 differ from traditional PCBs?

RT/duroid 6002 excels in high-frequency and microwave applications compared to traditional PCBs, featuring low loss, high dielectric constant, relative stability, and excellent mechanical performance.

In which applications is RT/duroid 6002 commonly used?

RT/duroid 6002 is widely used in the design of RF and microwave circuits, including antennas, power dividers, couplers, filters, and other high-frequency applications.

Why choose RT/duroid 6002 PCB?

Engineers choose RT/duroid 6002 PCB primarily for its outstanding performance in high-frequency environments, including low loss, high dielectric constant, and relative stability.

How is the mechanical performance of RT/duroid 6002 PCB?

RT/duroid 6002 exhibits excellent mechanical strength and stability, making it suitable for applications with stringent mechanical requirements.

Is RT/duroid 6002 suitable for high-temperature environments?

Yes, RT/duroid 6002 is designed to withstand high-temperature environments, ensuring reliable performance in high-temperature applications.

What should engineers pay attention to in the design process?

In the design process, engineers need to consider the electrical characteristics of RT/duroid 6002, ensuring the rational utilization of its low loss, high dielectric constant, and relative stability.

What about the cost of RT/duroid 6002?

RT/duroid 6002 is typically a high-performance material and may be more expensive compared to traditional PCBs. When choosing, application requirements and cost factors need to be considered.

Can Rogers RT/duroid 6002 PCBs Revolutionize Electronic Designs?

Rogers RT/duroid 6002 PCBs have the potential to revolutionize electronic designs. Here are some factors that could make them revolutionary in the field of electronic design:

High-Performance RF Design: The exceptional electrical properties of RT/duroid 6002 PCBs make them an ideal choice for high-performance RF design. Their low loss, high dielectric constant, and relative stability contribute to improved performance in RF systems.

Microwave Circuit Applications: Due to their excellent performance in the microwave frequency range, RT/duroid 6002 PCBs are widely used in microwave circuit design. This includes applications such as antennas, filters, power dividers, and other microwave components.

High-Temperature Applications: The design of RT/duroid 6002 PCBs is suitable for high-temperature environments, potentially revolutionizing industries such as aerospace and military systems where high temperatures are a critical factor.

Communication Systems: In communication systems, especially in applications requiring high-frequency stability and reliability, the use of RT/duroid 6002 PCBs could set new standards in design.

Emerging Technology Fields: With the development of emerging technologies such as 5G communication, the Internet of Things (IoT), and high-speed data transfer, RT/duroid 6002 PCBs may provide innovative design solutions for these rapidly evolving fields.

In summary, Rogers RT/duroid 6002 PCBs, due to their outstanding performance in high-frequency, microwave, and high-temperature environments, have the potential to bring about significant changes in the field of electronic design. They provide engineers with a superior tool to meet the increasing demands for circuit performance and reliability.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier