What is Rogers RT/duroid 5880 PCB?

Rogers RT/duroid 5880 PCB Supplier,Rogers RT/duroid 5880 PCB is an advanced laminate material known for its exceptional electrical performance in high-frequency applications. With a low dielectric constant and loss tangent, it ensures minimal signal loss and superior signal integrity. This substrate offers excellent dimensional stability and thermal conductivity, making it suitable for demanding RF and microwave circuits. Rogers RT/duroid 5880 PCB is widely utilized in aerospace, defense, and telecommunications industries, where reliability and performance are paramount. Its precise material properties and robust construction enable the development of compact, high-density electronic assemblies with enhanced efficiency and durability in challenging environments.

RT/duroid 5880 laminates has a low dielectric constant (Dk) and low dielectric loss, making them well suited for high frequency/broadband applications. Helping to maintain the Dk uniformity are the randomly oriented microfibers reinforcing the PTFE composites.

Features

- Dk or 2.20 +/- .02

- Dissipation factor of .0009 at 10GHz

- Low moisture absorption

- Isotropic

Benefits

- Uniform electrical properties over wide frequency range

- Easily cut, shared and machined to shape

- Resistant to solvents and reagents used in etching or plating edges and holes

- Ideal for high moisture environments

- Well-established material

- Lowest electrical loss for reinforced PTFE material

Rogers RT/duroid 5880 is a top-tier printed circuit board (PCB) designed explicitly for radio frequency (RF) and microwave applications. Developed by Rogers Corporation, this specialized composite material is a distinctive blend of organic glass reinforcement and polytetrafluoroethylene (PTFE). Its remarkable performance stands out in high-frequency and microwave environments, typically functioning within the gigahertz (GHz) range. It is widely used in wireless communication, radar systems, satellite communication, microwave RF equipment, and other applications that require high-performance RF characteristics.

RT/duroid 5880 features low loss, low dispersion, excellent dielectric constant, and dielectric loss tangent properties. These characteristics make it an ideal choice in high-frequency RF circuit designs, as they help minimize energy loss and signal distortion during the signal transmission process.

In summary, Rogers RT/duroid 5880 PCB is extensively utilized in fields requiring high-performance RF characteristics, especially in applications that demand high signal quality, bandwidth, and frequency stability.

Rogers RT/duroid 5880 PCB Supplier

What Functions Does RT/duroid 5880 PCB Serve?

RT/duroid 5880 PCB serves primarily in high-performance radio frequency (RF) and microwave applications, with functions including:

RF Communication: RT/duroid 5880 PCB plays a crucial role in wireless communication systems, supporting the transmission of high-frequency signals in applications such as mobile communication base stations and satellite communication systems.

Radar Systems: Due to its excellent high-frequency characteristics, RT/duroid 5880 PCB is widely used in radar systems, aiding in precise radar signal processing and detection.

Microwave RF Equipment: The material excels in the microwave frequency range, making it suitable for various microwave RF devices, including microwave receivers, transmitters, and other radar applications.

Satellite Communication: RT/duroid 5880 PCB is applied in satellite communication systems due to its requirements for high-frequency characteristics, ensuring reliable transmission of satellite signals.

High-Performance RF Circuit Design: The material is an ideal choice in high-frequency RF circuit design and is used to manufacture high-performance components such as antennas, amplifiers, filters, etc., ensuring signal quality and stability.

In summary, RT/duroid 5880 PCB plays a key role in applications that demand high-performance RF characteristics, providing a reliable foundation for various communication and radar systems.

| PROPERTY | TYPICAL VALUES | DIRECTION | UNITS⁽³⁾ | CONDITION | TEST METHOD | |

| [1]Dielectric Constant,εr cess | 2.20

2.20 ± 0.02 spec. |

Z

Z |

N/A | C24/23/50

C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5 |

|

| [4]Dielectric Constant, er Design | 2.20 | Z | N/A | 8 GHz – 40 GHz | Differential Phase Length

Method |

|

| Dissipation Factor, tan δ | 0.0004

0.0009 |

Z

Z |

N/A | C24/23/50

C24/23/50 |

1 MHz IPC-TM-650, 2.5.5.3

10 GHz IPC-TM-2.5.5.5 |

|

| Thermal Coefficient of εr | -125 | Z | ppm/°C | -50 – 150°C | IPC-TM-650, 2.5.5.5 | |

| Volume Resistivity | 2 X 10⁷ | Z | Mohm cm | C96/35/90 | ASTM D257 | |

| Surface Resistivity | 3X 10⁷ | Z | Mohm | C/96/35/90 | ASTM D257 | |

| Specific Heat | 0.96 (0.23) | N/A | J/g/K

(cal/g/C) |

N/A | Calculated | |

| Tensile Modulus | Test at

23 °C |

Test at 100

°C |

N/A | MPa (kpsi) | A | ASTM D638 |

| 1070 (156) | 450 (65) | X | ||||

| 860 (125) | 380 (55) | Y | ||||

| ultimate stress | 29 (4.2) | 20 (2.9) | X | |||

| 27 (3.9) | 18 (2.6) | Y | ||||

| ultimate strain | 6.0 | 7.2 | X | % | ||

| 4.9 | 5.8 | Y | ||||

| Compressive Modulus | 710 (103) | 500 (73) | X | MPa (kpsi) | A | ASTM D695 |

| 710 (103) | 500 (73) | Y | ||||

| 940 (136) | 670 (97) | Z | ||||

| ultimate stress | 27 (3.9 | 22 (3.2) | X | |||

| 29 (5.3) | 21 (3.1) | Y | ||||

| 52 (7.5) | 43 (6.3) | Z | ||||

| ultimate strain | 8.5 | 8.4 | X | % | ||

| 7.7 | 7.8 | Y | ||||

| 12.5 | 17.6 | Z | ||||

| Moisture Absorption | 0.02 | N/A | % | .062” (1.6mm)

D48/50 |

ASTM D570 | |

| Thermal Conductivity | 0.20 | Z | W/m/K | 80°C | ASTM C518 | |

| Coefficient of

Thermal Expansion |

31

48 237 |

X

Y Z |

ppm/°C | 0-100°C | IPC-TM-650, 2.4.41 | |

| Td | 31.2 (5.5) | N/A | °C TGA | N/A | ASTM D3850 | |

| Density | 2.2 | N/A | gm/cm³ | N/A | ASTM D792 | |

| Copper Peel | 31.2 (5.5) | N/A | pli (N/mm) | 1 oz (35mm) EDC

foil after solder float |

IPC-TM-650 2.4.8 | |

| Flammability | V-0 | N/A | N/A | N/A | UL94 | |

| Lead-Free Process

Compatible |

Yes | N/A | N/A | N/A | N | |

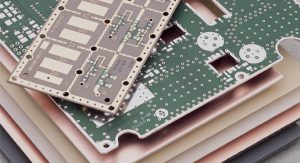

Are There Different Types of Substrates, and Where Does RT/duroid 5880 PCB Fit?

There are various types of printed circuit board (PCB) substrates, and RT/duroid 5880 is a specific high-performance substrate designed for radio frequency (RF) and microwave applications. Here are some common types of PCB substrates:

FR-4: This substrate is frequently employed in general electronic devices and applications operating at lower frequencies, featuring a reinforced epoxy resin with glass fibers.

Aluminum Substrate: By employing aluminum as a thermally conductive substrate, it proves effective in applications that demand efficient heat dissipation, such as in LED lighting.

PTFE Substrate:PTFE substrates are commonly employed in high-frequency and microwave applications owing to their minimal signal loss and outstanding insulation characteristics.

Rogers Series: Products from Rogers Corporation, including RT/duroid 5880, belong to high-performance PTFE substrates designed specifically for high-frequency and microwave applications.

RT/duroid 5880 PCB is primarily used in applications that demand high RF characteristics, such as:

High-Frequency RF Circuit Design: RT/duroid 5880 is suitable for manufacturing high-performance components like antennas, filters, amplifiers, ensuring low signal loss and stability in the high-frequency range.

Microwave Equipment: Due to its superior performance in the microwave frequency range, RT/duroid 5880 PCB is widely used in microwave receivers, transmitters, and other devices.

Radar Systems: In radar systems, high-performance RF materials like RT/duroid 5880 are required to ensure precise signal processing and detection.

In summary, RT/duroid 5880 PCB plays a crucial role in specific applications with stringent requirements for high-frequency and microwave performance.

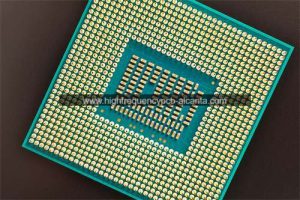

How Does RT/duroid 5880 PCB Relate to IC Packaging?

The relationship between RT/duroid 5880 PCB and integrated circuit (IC) packaging primarily lies in the connection and support for radio frequency (RF) and microwave applications. Here are some aspects of the relevance between RT/duroid 5880 PCB and IC packaging:

RF Modules: RT/duroid 5880 PCB can be used to manufacture RF modules, which typically include RF circuits, antennas, and other related components. These modules can be integrated into IC packaging to support wireless communication, radar systems, and other applications.

Antenna Integration: The high performance of RT/duroid 5880 PCB makes it an ideal choice for antenna manufacturing. In certain IC packaging, especially where compact design and high-performance RF connections are required, RF antennas can be directly integrated into the PCB.

High-Frequency Signal Transmission: The low loss and excellent high-frequency characteristics of RT/duroid 5880 PCB make it suitable for supporting applications within IC packaging that require high-frequency signal transmission. This is crucial for maintaining signal quality in the high-frequency range.

Microwave Connections: For applications requiring signal transmission in the microwave frequency range, RT/duroid 5880 PCB can be used to connect microwave components and IC packaging, ensuring the stability of signal transmission.

In summary, RT/duroid 5880 PCB can be utilized in IC packaging to support high-performance RF and microwave applications, providing critical functions for connection and signal transmission. This integration helps optimize the performance of RF systems and enables the implementation of complex high-frequency circuit designs within compact packaging spaces.

What Sets RT/duroid 5880 PCB Apart from Traditional PCBs?

RT/duroid 5880 PCB stands out from traditional PCBs in several significant ways:

High-Performance RF Characteristics: Designed specifically for high-performance radio frequency (RF) and microwave applications, RT/duroid 5880 PCB exhibits outstanding high-frequency characteristics. In the high-frequency range, RT/duroid 5880 PCB outperforms traditional PCBs, showcasing superior characteristics such as minimal signal loss, low dispersion, and excellent dielectric properties, including dielectric constant and loss tangent.

Special Material Composition: RT/duroid 5880 utilizes a composite material composed of organic glass-reinforced polytetrafluoroethylene (PTFE), endowing it with distinctive characteristics. In contrast to common PCB materials like glass-reinforced epoxy resin (FR-4), the material composition of RT/duroid 5880 is better suited for high-frequency RF environments.

Low Loss: Due to the special design of its material, RT/duroid 5880 PCB demonstrates lower signal loss. This makes it more suitable for applications requiring long-distance high-frequency signal transmission or high signal quality.

Microwave Applications: RT/duroid 5880 PCB excels in the microwave frequency range, making it suitable for microwave RF equipment, radar systems, and other applications. This superior performance in high-frequency microwave environments sets it apart from traditional PCBs.

In summary, the design and performance of RT/duroid 5880 PCB in high-frequency RF and microwave applications make it more prominent and suitable for specific fields compared to traditional PCBs.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings | |

| 0.005” (0.127mm) +/- 0.0005”

0.010” (0.252mm) +/- 0.0007” 0.020” (0.508mm) +/- 0.0015” 0.031” (0.787mm) +/- 0.0020” 0.062” (1.575mm) +/- 0.0030” *Additional thicknesses available from 0.0035” – 0.375” in varying increments |

18” X 12” (457 X 305mm)

18” X 24” (457 X 610mm) *Additional panel sizes available |

Electrodeposited Copper Foil

½ oz. (18µm) HH/HH 1 oz. (35µm) H1/H1 |

Electrodeposited Copper Foil

½ oz. (18µm) HH/HH 1 oz. (35µm) H1/H1 |

| *Additional claddings, such as heavy metal, resistive foil and unclad are available

*Contact Customer Service or Sales Engineering to inquire about additional available product configurations |

|||

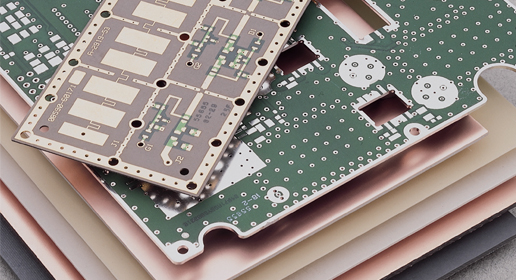

What Comprises the Structure and Production Technologies of RT/duroid 5880 PCB?

The structure and production technologies of RT/duroid 5880 PCB include the following aspects:

Substrate Structure: The substrate of RT/duroid 5880 PCB is made of an organic glass-reinforced polytetrafluoroethylene (PTFE) composite material. This combination provides excellent high-frequency characteristics, including low loss and outstanding insulation properties.

Conductive Layer: A conductive layer, typically made of copper, is coated on the substrate. The pattern of the conductive layer forms the circuit connections, and excess copper is removed through processes like chemical etching or mechanical machining to create the required circuit pattern.

Coating: To protect the conductive layer and provide additional insulation, RT/duroid 5880 PCB is usually coated with a protective layer. This safeguards the circuit against external environmental influences, ensuring both stability and long-term reliability.

Layered Structure: Printed circuit boards (PCBs) commonly adopt a multi-layered configuration achieved through the lamination of multiple layers.This includes the alternating stacking of the substrate, conductive layers, and insulation layers to meet the requirements of circuit design.

Production Technologies: PCB manufacturing involves a series of process steps, including design, photolithography, etching, chemical deposition, lamination, and final processing. The production of RT/duroid 5880 PCB typically requires specialized high-precision equipment and processes to ensure the preservation of high-performance RF characteristics.

In summary, the structure of RT/duroid 5880 PCB consists of a substrate, conductive layer, and protective layer, and its production technologies involve multiple steps requiring high-precision manufacturing processes.

What Are the Frequently Asked Questions (FAQs) about RT/duroid 5880 PCB?

What is RT/duroid 5880 PCB?

RT/duroid 5880 PCB is a high-performance printed circuit board (PCB) material designed specifically for radio frequency (RF) and microwave applications.

What are the applications of RT/duroid 5880 PCB?

The material is primarily used in applications that demand high-performance RF characteristics, including wireless communication, radar systems, satellite communication, etc.

What are the advantages of RT/duroid 5880 PCB compared to traditional PCBs?

Compared to traditional PCBs, RT/duroid 5880 PCB offers excellent high-frequency characteristics, low loss, and outstanding insulation properties, making it stand out in high-performance RF and microwave applications.

How is RT/duroid 5880 PCB manufactured?

The manufacturing process of RT/duroid 5880 PCB involves special material composition and high-precision processes, including substrate preparation, conductive layer coating, pattern formation, lamination, and final processing.

In which application areas is RT/duroid 5880 PCB suitable?

The material is suitable for applications that require high-performance RF characteristics, such as high-frequency RF circuit design, microwave equipment, radar systems, etc.

What are the thermal characteristics of RT/duroid 5880 PCB?

RT/duroid 5880 PCB exhibits excellent thermal performance, making it suitable for applications that require resistance to high-temperature environments.

What is the production cost of RT/duroid 5880 PCB?

Producing RT/duroid 5880 PCB typically involves special materials and manufacturing processes, which may result in some cost differences compared to traditional PCBs.

What are the specific design considerations for RT/duroid 5880 PCB?

When designing RT/duroid 5880 PCB, it is crucial to consider its unique high-frequency characteristics to ensure optimal circuit performance.

Can We Conclude Anything about RT/duroid 5880 PCB?

About RT/duroid 5880 PCB, we can draw the following conclusions:

Designed for High-Performance RF and Microwave Applications: RT/duroid 5880 PCB is a type of printed circuit board (PCB) material specifically engineered for high-performance radio frequency (RF) and microwave applications. Its unique material composition and manufacturing processes make it excel in high-frequency environments.

Outstanding High-Frequency Characteristics: RT/duroid 5880 PCB possesses exceptional high-frequency characteristics, including low loss, low dispersion, excellent dielectric constant, and dielectric loss tangent properties. This makes it an ideal choice for high-performance RF circuit design and microwave applications.

Suitable for Various Application Areas: The material is suitable for various application areas that require high-performance RF characteristics, including wireless communication, radar systems, satellite communication, and microwave RF equipment.

Special Material Composition: RT/duroid 5880 PCB employs an organic glass-reinforced polytetrafluoroethylene (PTFE) composite material. Relative to traditional PCB materials like glass-reinforced epoxy resin (FR-4), its material composition is better suited for high-frequency RF environments.

Requires Specialized Manufacturing Processes: The manufacturing of RT/duroid 5880 PCB involves specialized high-precision equipment and processes to ensure the material’s outstanding performance is maintained throughout the manufacturing process.

In summary, RT/duroid 5880 PCB is a specialized printed circuit board material that excels in high-performance RF and microwave applications. When selecting and applying it, consideration of its unique design characteristics is crucial to ensure optimal performance.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier