What Is Rogers RT/duroid 5870 PCB?

Rogers RT/duroid 5870 PCB Supplier,Rogers RT/duroid 5870 PCB is a high-performance material renowned for its exceptional electrical properties in RF and microwave applications. With a low dielectric constant and loss tangent, it ensures minimal signal loss and high-speed transmission. This substrate offers excellent dimensional stability and thermal conductivity, making it ideal for demanding environments. Rogers RT/duroid 5870 PCB is widely used in aerospace, defense, and telecommunications industries, where reliability and performance are crucial. Its advanced material composition and precise manufacturing processes enable the development of compact, high-density electronic assemblies with superior signal integrity and thermal management capabilities.

Professional Rogers RT/duroid 5870 PCB manufacturer. high frequency packaging substrates with ultra-small trace width and pitch, we produce high quality substrates (PCB) from 2 to 50 layers.

RT/duroid 5870 laminates offer high frequency with low dielectric constant (Dk). The randomly oriented microfibers in the PTFE composites result in exceptional Dk uniformity. With its low Dk loss, RT/duroid 5870 laminates are well suited for high frequency/broadband applications where dispersion and losses need to be minimized.

Features

- Dk of 2.33 +/- .02

- Dissipation factor of .0012 at 10GHz

- Low moisture absorption

- Isotropic

Benefits

- Lowest electrical loss for reinforced PTFE material

- Easily cut, shared and machined to shape

- Resistant to solvents and reagents used in etching or plating edges and holes

- Ideal for high moisture environments

- Well-established material

- Uniform electrical properties over wide frequency range

Rogers RT/duroid 5870 is a high-frequency PCB material primarily used in wireless communication, microwave, and radio frequency applications. It is an organic glass-reinforced polyimide composite material manufactured by the American company Rogers Corporation. RT/duroid 5870 exhibits excellent electrical properties, including low loss, low dielectric constant, and stability at high frequencies.

This material is commonly used in the fabrication of high-frequency circuit boards, such as antennas, microwave frequency amplifiers, radio frequency filters, and more. Due to its outstanding performance, RT/duroid 5870 finds widespread application in the field of communications, especially in applications that demand high-frequency stability and low signal loss.

In summary, Rogers RT/duroid 5870 PCB is an advanced PCB material designed specifically for high-frequency, microwave, and radio frequency circuit applications.

Rogers RT/duroid 5870 PCB Supplier

What Function Does Rogers RT/duroid 5870 PCB Serve?

Rogers RT/duroid 5870 PCB is primarily used for high-frequency microwave, and radio frequency circuit applications. Its main functions include:

Low Signal Loss: RT/duroid 5870 exhibits low loss characteristics, suitable for applications that require minimal signal attenuation, ensuring effective transmission of high-frequency signals.

High-Frequency Stability: The material maintains stable performance at high frequencies, making it an ideal choice for manufacturing wireless communication devices, radar systems, and other high-frequency electronic equipment.

Low Dielectric Constant: The low dielectric constant of RT/duroid 5870 helps reduce signal propagation delay, improving circuit performance, especially in applications that require precise timing.

Microwave Frequency Applications: Due to its outstanding performance, RT/duroid 5870 is frequently used in the fabrication of microwave frequency amplifiers, radio frequency filters, antennas, and other microwave circuits.

In summary, Rogers RT/duroid 5870 PCB is primarily employed to ensure the stability of high-frequency circuits, reduce signal loss, and provide excellent performance in the microwave frequency range.

| PROPERTY | TYPICAL VALUES | DIRECTION | UNITS⁽³⁾ | CONDITION | TEST METHOD | |

| [1]Dielectric Constant,εr cess | 2.33

2.33 ± 0.02 spec. |

Z

Z |

N/A | C24/23/50

C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5 |

|

| [4]Dielectric Constant, er Design | 2.33 | Z | N/A | 8 GHz – 40 GHz | Differential Phase Length

Method |

|

| Dissipation Factor, tan δ | 0.0005

0.0012 |

Z

Z |

N/A | C24/23/50

C24/23/50 |

1 MHz IPC-TM-650, 2.5.5.3

10 GHz IPC-TM-2.5.5.5 |

|

| Thermal Coefficient of εr | -115 | Z | ppm/°C | -50 – 150°C | IPC-TM-650, 2.5.5.5 | |

| Volume Resistivity | 2 X 10⁷ | Z | Mohm cm | C96/35/90 | ASTM D257 | |

| Surface Resistivity | 2 X 10⁷ | Z | Mohm | C/96/35/90 | ASTM D257 | |

| Specific Heat | 0.96 (0.23) | N/A | J/g/K

(cal/g/C) |

N/A | Calculated | |

| Tensile Modulus | Test at

23 °C |

Test at 100

°C |

N/A | MPa (kpsi) | A | ASTM D638 |

| 1300 (189) | 490 (71) | X | ||||

| 1280 (185) | 430 (63) | Y | ||||

| ultimate stress | 50 (7.3) | 34 (4.8) | X | |||

| 42 (6.1) | 34 (4.8) | Y | ||||

| ultimate strain | 9.8 | 8.7 | X | % | ||

| 9.8 | 8.6 | Y | ||||

| Compressive Modulus | 1210 (176) | 680 (99) | X | MPa (kpsi) | A | ASTM D695 |

| 1360 (198) | 860 (125) | Y | ||||

| 803 (120) | 520 (76) | Z | ||||

| ultimate stress | 30 (4.4) | 23 (3.4) | X | |||

| 37 (5.3) | 25 (3.7) | Y | ||||

| 54 (7.8) | 37 (5.3) | Z | ||||

| ultimate strain | 4 | 4.3 | X | % | ||

| 3.3 | 3.3 | Y | ||||

| 8.7 | 8.5 | Z | ||||

| Moisture Absorption | 0.02 | N/A | % | .062” (1.6mm)

D48/50 |

ASTM D570 | |

| Thermal Conductivity | 0.22 | Z | W/m/K | 80°C | ASTM C518 | |

| Coefficient of

Thermal Expansion |

22

28 173 |

X

Y Z |

ppm/°C | 0-100°C | IPC-TM-650, 2.4.41 | |

| Td | 500 | N/A | °C TGA | N/A | ASTM D3850 | |

| Density | 2.2 | N/A | gm/cm³ | N/A | ASTM D792 | |

| Copper Peel | 27.2 (4.8) | N/A | pli (N/mm) | 1 oz (35mm) EDC

foil after solder float |

IPC-TM-650 2.4.8 | |

| Flammability | V-0 | N/A | N/A | N/A | UL94 | |

| Lead-Free Process

Compatible |

Yes | N/A | N/A | N/A | N/A | |

What Are the Types of Package Substrate, and How Does Rogers RT/duroid 5870 Fit In?

Package substrates come in various types, with some key categories being:

FR-4 (Flame Retardant 4): FR-4 is a widely used substrate made from glass-reinforced epoxy resin, commonly employed in the production of general electronic devices. However, its performance may be limited in high-frequency and microwave applications.

RO4350B: RO4350B is a specialized composite material comprising PTFE (Polytetrafluoroethylene) and glass fiber. It is designed for high-frequency and microwave circuits, offering low loss and stable performance.

Rogers RT/duroid 5870: As mentioned earlier, RT/duroid 5870 is an organic glass-reinforced polyimide composite material manufactured by Rogers Corporation. It is designed specifically for high-frequency, microwave, and radio frequency circuits, featuring low loss, high-frequency stability, and a low dielectric constant.

Rogers RT/duroid 5870 excels in high-frequency and microwave applications, particularly in scenarios that demand higher performance, such as radar systems, communication devices, and satellite communication. Compared to general-purpose FR-4 substrates, RT/duroid 5870 is better suited to meet stringent requirements for signal transmission quality and circuit performance. Therefore, for applications that require high-frequency stability and low signal loss, Rogers RT/duroid 5870 is an ideal choice.

How Does Rogers RT/duroid 5870 PCB Compare to Traditional PCBs?

Rogers RT/duroid 5870 PCB has several advantages over traditional Printed Circuit Boards (PCBs):

High-Frequency Performance: RT/duroid 5870 PCB excels at high frequencies, exhibiting lower signal loss and high-frequency stability. In contrast, traditional PCBs, especially those using common FR-4 materials, may experience significant signal attenuation in high-frequency applications.

Low Dielectric Constant: RT/duroid 5870 has a lower dielectric constant, contributing to reduced signal propagation delay and improved circuit performance. Traditional PCB materials tend to have higher dielectric constants, potentially leading to slower signal transmission.

Stability: Due to the material characteristics of RT/duroid 5870, it demonstrates stability in varying environmental conditions, including temperature and humidity changes. Traditional PCBs may experience performance fluctuations in extreme environmental conditions.

Microwave Applications: RT/duroid 5870 PCB is suitable for microwave frequency applications, such as radar, communication devices, and satellite communication. This makes it more suitable for high-performance and complex applications.

In summary, Rogers RT/duroid 5870 PCB excels in high-frequency and microwave circuit applications, providing superior performance and stability compared to traditional PCBs. However, due to its higher cost, the choice between these types of PCBs depends on the specific requirements of the application and budget considerations.

What Is the Main Structure and Production Technologies of Rogers RT/duroid 5870 PCB?

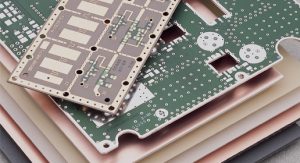

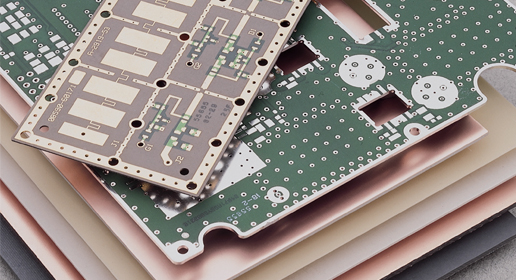

The main structure of Rogers RT/duroid 5870 PCB includes substrate and metal foil, and the production process involves the following key technologies:

Substrate: The substrate of RT/duroid 5870 is an organic glass-reinforced polyimide composite material. This substrate has excellent high-frequency performance, low dielectric constant, and stability, making it suitable for high-frequency, microwave, and radio frequency circuits.

Metal Foil: PCB manufacturing typically involves covering the substrate with a layer of metal foil, usually copper foil. The metal foil is used to form circuit patterns, conductive paths, and connectors.

Layer Stacking: RT/duroid 5870 PCB is typically a multilayer structure, consisting of multiple stacked layers of substrate and metal foil. This multilayer structure allows for signal transmission between different layers and provides higher integration.

Chemical Processing: During the manufacturing process, chemical procedures may be employed, including acid etching or chemical deposition, to eliminate undesired materials, cleanse the metal surfaces, and uphold the circuit board’s quality.

Silk Screen and Coating: During the concluding phases of the manufacturing process, silk screen printing and coating are commonly employed. These steps serve to mark component locations, identify the circuit board, and apply a protective coating.

In summary, the production process of Rogers RT/duroid 5870 PCB involves selecting high-performance substrate, preparing metal foil, multilayer stacking, chemical processing, and final printing and coating steps to ensure the circuit board meets the requirements of high-frequency, microwave, and radio frequency applications.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings | |

| 0.005” (0.127mm) +/- 0.0005”

0.010” (0.252mm) +/- 0.0007” 0.020” (0.508mm) +/- 0.0015” 0.031” (0.787mm) +/- 0.0020” 0.062” (1.575mm) +/- 0.0030” *Additional thicknesses available from 0.0035” – 0.375” in varying increments |

18” X 12” (457 X 305mm)

18” X 24” (457 X 610mm) *Additional panel sizes available |

Electrodeposited Copper Foil

½ oz. (18µm) HH/HH 1 oz. (35µm) H1/H1 |

Electrodeposited Copper Foil

½ oz. (18µm) HH/HH 1 oz. (35µm) H1/H1 |

| *Additional claddings, such as heavy metal, resistive foil and unclad are available

*Contact Customer Service or Sales Engineering to inquire about additional available product configurations |

|||

What Are Frequently Asked Questions About Rogers RT/duroid 5870 PCB?

What is RT/duroid 5870 made of?

RT/duroid 5870 is an organic glass-reinforced polyimide composite material manufactured by Rogers Corporation, designed specifically for high-frequency, microwave, and radio frequency circuits.

What are the main features of RT/duroid 5870 PCB?

RT/duroid 5870 PCB has excellent high-frequency performance, low dielectric constant, low signal loss, and stability at high frequencies.

In which applications is RT/duroid 5870 commonly used?

RT/duroid 5870 is widely used in the manufacturing of high-frequency circuits, such as antennas, microwave frequency amplifiers, radio frequency filters, especially in communication and radar systems.

How does RT/duroid 5870 differ from regular FR-4 materials?

Compared to regular FR-4 materials, RT/duroid 5870 performs better in high-frequency and microwave applications, with lower signal loss and higher performance stability.

What is the manufacturing process of RT/duroid 5870 PCB?

The manufacturing process of RT/duroid 5870 PCB involves selecting high-performance substrates, preparing metal foils, multilayer stacking, chemical processing, and final printing and coating steps.

What is the cost of RT/duroid 5870 PCB?

The cost of RT/duroid 5870 PCB is relatively high, mainly dependent on material costs and manufacturing complexity. In high-performance and specific applications, its superior characteristics may justify the cost.

How is the temperature and humidity stability of RT/duroid 5870 PCB?

RT/duroid 5870 PCB exhibits good temperature and humidity stability, making it suitable for high-performance applications in different environmental conditions.

In Conclusion, How Does Rogers RT/duroid 5870 PCB Shape the Future of Electronics?

In shaping the future of electronics, Rogers RT/duroid 5870 PCB plays a crucial role, manifested in several key aspects:

Advancing Wireless Communication Technology with High-Frequency Performance: The outstanding high-frequency performance, low signal loss, and high stability of RT/duroid 5870 PCB contribute to the progress of wireless communication technology. With the increasing demand for high-frequency circuits in 5G and future communication standards, RT/duroid 5870 provides a reliable solution for these applications.

Critical Material for Microwave and Radio Frequency Applications: In applications such as radar systems, satellite communication, and microwave frequencies, RT/duroid 5870 PCB’s superior performance makes it a critical material. This contributes to driving innovation and technological development in these fields.

Enhancing Circuit Performance and Integration: The multilayer structure and excellent electrical performance of RT/duroid 5870 PCB improve circuit performance and integration. This aligns with the trend in modern electronic devices requiring smaller, lighter, and more powerful circuit boards.

Supporting High-Performance Computing and Data Transmission: With the development of big data, artificial intelligence, and cloud computing, there is a growing demand for high-performance computing and data transmission. RT/duroid 5870 PCB can meet the requirements for high-frequency and high-speed circuit boards in these fields.

In summary, Rogers RT/duroid 5870 PCB, through its exceptional performance, provides support for innovation in the electronics industry. In the future, as wireless communication, microwave technology, and high-performance computing continue to evolve, RT/duroid 5870 PCB is poised to play an increasingly vital role in driving advancements at the forefront of electronic technology.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier