What is Rogers 4450F PCB?

Rogers 4450F PCB Manufacturer,Rogers 4450F PCB is a high-frequency laminate material renowned for its exceptional electrical performance and reliability. With a low dielectric constant and loss tangent, it ensures minimal signal loss and high-speed transmission. This substrate offers excellent dimensional stability and thermal conductivity, making it suitable for demanding RF and microwave applications. Rogers 4450F PCB is widely used in aerospace, defense, and telecommunications industries, where reliability and performance are critical. Its advanced material composition and precise manufacturing processes enable the development of compact, high-density electronic assemblies with superior signal integrity and thermal management capabilities.

Rogers 4450F is a specific type of printed circuit board (PCB) material manufactured by Rogers Corporation. This material possesses special electrical properties suitable for high-frequency and microwave applications. Key features of Rogers 4450F PCB material include low loss, high-frequency performance, dimensional stability, and excellent control of dielectric constant.

This PCB material is typically used in devices that operate in the high-frequency range, such as radio frequency (RF) and microwave circuits, antenna systems, radar systems, and more. Due to its outstanding performance, Rogers 4450F PCB is widely employed in applications where stringent electrical performance requirements are essential.

Rogers 4450F PCB Manufacturer

What Makes Rogers 4450F PCBs Stand Out?

The outstanding features of Rogers 4450F PCB primarily include its excellent high-frequency performance, low loss, dimensional stability, and precise control of the dielectric constant. Here are distinctive features that differentiate it:

Excellent High-Frequency Performance: Rogers 4450F PCB stands out for its superior performance in high-frequency applications, rendering it a preferred option for radio frequency (RF) and microwave circuits.

Low Loss: Low loss is a crucial feature of this material, helping to minimize energy loss during signal transmission, maintaining signal clarity, and strength.

Dimensional Stability: Rogers 4450F PCB exhibits good dimensional stability, meaning that its physical dimensions change minimally under different temperature and environmental conditions. This enhances the stability and dependability of the equipment.

Precise Control of Dielectric Constant: The material offers precise management of the dielectric constant, a critical factor in guaranteeing uniformity and optimal performance in circuit design.

Overall, Rogers 4450F PCB, with its outstanding performance in high-frequency applications, is widely used in various fields that demand high-performance circuit boards.

| Standard Thicknesses | Standard Panel Sizes |

| 0.0040” (0.102 mm) +/- 0.0006”

*Contact Customer Service or Sales Engineering to inquire |

16” X 18” (406 X 457mm)

24” X 18” (610 X 457mm) 24.5” X 18.5” (622 X 470mm) 24” X 36” (610 X 915 mm) *Additional panel sizes available |

What Functions Do Rogers 4450F PCBs Serve?

Rogers 4450F PCBs are primarily used in high-frequency and microwave circuit applications, including but not limited to the following functions:

Radio Frequency (RF) Circuits: Rogers 4450F PCBs find extensive applications in RF circuit designs, including communication devices, RF amplifiers, and receivers, owing to their outstanding high-frequency performance.

Microwave Circuits: Rogers 4450F PCBs find extensive applications in RF circuit designs, including communication devices, RF amplifiers, and receivers, owing to their outstanding high-frequency performance.

Antenna Systems: Used in the design of antenna systems to ensure efficient signal transmission and reception.

High-Performance Radar Systems: In radar technology, Rogers 4450F PCBs can be employed to build high-performance radar systems, meeting high requirements for electrical performance and stability.

Wireless Communication Devices: Applied in the design of wireless communication devices to ensure the reliability and efficiency of signal transmission.

Overall, Rogers 4450F PCBs, with their exceptional electrical performance, primarily serve applications that require high frequency, low loss, and dimensional stability, making them a crucial component in many advanced electronic systems.

What Sets Rogers 4450F Apart in the Spectrum of Package Substrates?

Rogers 4450F stands out in the field of package substrates for several reasons:

Outstanding High-Frequency Performance: Rogers 4450F PCB demonstrates exceptional performance in the high-frequency range, making it particularly suitable for RF and microwave applications. This sets it apart from other package substrates, especially in scenarios that demand high-frequency capabilities.

Low Loss: The 4450F PCB features low-loss characteristics, aiding in minimizing energy loss during signal transmission and ensuring excellent performance at high frequencies.

Dimensional Stability: Rogers 4450F PCB exhibits excellent dimensional stability, meaning that its physical dimensions change relatively little even under varying temperatures and environmental conditions. This ensures the reliability of the package substrate.

Precise Control of Dielectric Constant: The material allows for precise control of the dielectric constant, contributing to design consistency and meeting stringent electrical performance requirements for specific applications.

Overall, Rogers 4450F stands out in the field of package substrates due to its outstanding performance in high-frequency capabilities, low loss, dimensional stability, and control over the dielectric constant.

How Do Rogers 4450F PCBs Compare to Traditional PCBs?

Rogers 4450F PCBs exhibit significant differences from traditional PCBs in several aspects:

High-Frequency Performance: Rogers 4450F PCBs are specifically designed for high-frequency applications with outstanding performance in RF and microwave circuits. In contrast, traditional PCBs may have inferior performance at high frequencies.

Low Loss: Rogers 4450F PCBs feature low-loss characteristics, aiding in minimizing energy loss during signal transmission. Traditional PCBs may not perform as well in this regard.

Dimensional Stability: Rogers 4450F PCBs demonstrate excellent dimensional stability, with minimal physical dimension changes even under varying temperatures and environmental conditions. Traditional PCBs may have more limited performance in this aspect.

Dielectric Constant Control: Rogers 4450F PCBs can precisely control the dielectric constant, crucial for applications with strict electrical performance requirements. Traditional PCBs may not achieve the same level of precision in dielectric constant control.

In summary, the superior performance of Rogers 4450F PCBs in high-frequency capabilities, low loss, dimensional stability, and dielectric constant control allows them to surpass traditional PCBs in specific applications. However, the choice between the two types of PCB depends on the specific requirements and performance standards of the application.

| Properties | RO4450F | Direction | Units | Test Conditions | Test Method | |

| Electrical Properties | ||||||

| Dielectric Constant | 3.52 ± 0.05 | Z | – | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Dissipation Factor | 0.004 | Z | – | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Volume Resistivity | 8.93 X10⁸ | – | Mohm-cm | C-96/35/90 | – | IPC TM-650 2.5.17.1 |

| Surface Resistivity | 1.03 X10⁷ | X,Y | Mohm | C-96/35/90 | – | IPC TM-650 2.5.17.1 |

| Electrical Strength (dielectric

strength) |

1000 | Z | V/mil | D-48/50 | – | IPC TM-650 2.5.6.2 |

| Thermal Properties | ||||||

| Decomposition Temperature (Td) | 390 | – | ˚C | 2hrs @ 105˚C | 5% Weight

Loss |

IPC TM-650 2.3.40 |

| Glass Transition (Tg) | >280 | – | ˚C TMA | A | – | IPC-TM-650 2.4.24.5 |

| Coefficient of Thermal Expansion | 19 | X | ppm/˚C | – | 55˚C to

288˚C |

IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion | 17 | Y | ppm/˚C | – | 55˚C to

288˚C |

IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion | 50 | Y | ppm/˚C | – | 55˚C to

288˚C |

IPC TM-650 2.4.41 |

| Thermal Conductivity | 0.65 | Z | W/(m.K) | 80˚C | z direction | ASTM D5470 |

| Mechanical Properties | ||||||

| Copper Peel Strength after Thermal

Stress |

0.70

(4.0) |

Z | N/mm

(lbs/in) |

10s @288˚C | 35 μm foil | IPC TM-650 2.4.8 |

| Physical Properties | ||||||

| Glass Transition (Tg) | 1080 | – | – | – | – | – |

| Resin-Content | 80 | – | – | – | – | – |

| Color | White | – | – | – | – | – |

| Flammability | V-0 | – | – | – | C48/23/50

& C168/70 |

UL 94 |

| Moisture Absorption | 0.04 | – | % | D24/23 | – | IPC TM-650 2.6.2.1 |

| Lead Free Process Compatible | Yes | – | – | – | – | – |

What Lies Within the Structure of Rogers 4450F PCBs, and How Are They Produced?

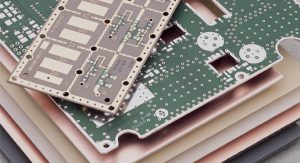

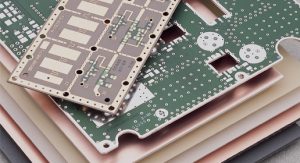

Rogers 4450F PCBs adopt a multilayer structure, consisting of the following main components:

Substrate Layer: Rogers 4450F PCBs use Rogers Corporation’s proprietary high-performance substrate, typically a glass-reinforced composite material with excellent high-frequency performance and electrical characteristics.

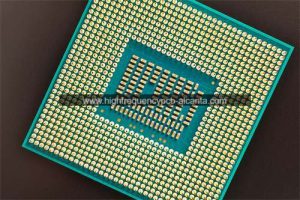

Copper Foil Layer: Multiple layers of copper foil are usually applied to the surface of the substrate. These copper foil layers serve as electrical conductors, forming circuitry and signal transmission paths.

Dielectric Layer: The dielectric layer is inserted between the copper foil layers and is typically made of a material with specific electrical properties. In Rogers 4450F, this layer is precisely designed to control the dielectric constant, influencing signal transmission speed and performance.

Cover Copper Layer: The top and bottom layers of the PCB are typically coated with a cover copper layer, serving to protect and reinforce the structure.

The manufacturing process of Rogers 4450F PCBs generally involves the following steps:

Material Preparation: Select and prepare the Rogers 4450F substrate and other necessary layer materials.

Lamination: Laminate the substrate, copper foil, and dielectric layers together according to the design requirements, forming a multilayer structure.

Chemical Processing: Use chemical processing methods to create circuit patterns by removing unwanted portions, exposing the required conductive paths.

Surface Treatment: Treat the exposed copper foil surfaces to enhance corrosion resistance and solderability.

Final Processing: Perform final cutting, drilling, and other processing steps according to design requirements to create the final PCB structure.

In summary, the structure and manufacturing process of Rogers 4450F PCBs are designed to meet the specific requirements of high-frequency and microwave applications, demanding precise design and manufacturing technologies.

What Are the Frequently Asked Questions (FAQs) about Rogers 4450F PCBs?

What is Rogers 4450F PCB?

Rogers 4450F PCB is a printed circuit board (PCB) material manufactured by Rogers Corporation, primarily used in high-frequency and microwave applications.

What are the key features of Rogers 4450F PCB?

Rogers 4450F PCB features excellent high-frequency performance, low loss, dimensional stability, and precise control of the dielectric constant.

Which applications is Rogers 4450F PCB suitable for?

Primarily employed in applications demanding superior high-frequency performance, Rogers 4450F PCB finds widespread use in radio frequency (RF) circuits, microwave circuits, antenna systems, radar systems, and similar contexts.

How does Rogers 4450F PCB differ from traditional PCBs?

Rogers 4450F PCB has advantages over traditional PCBs in terms of high-frequency performance, low loss, dimensional stability, and control of the dielectric constant.

How is Rogers 4450F PCB manufactured?

The manufacturing process typically involves material preparation, lamination, chemical processing, surface treatment, and final processing steps.

What is the cost of Rogers 4450F PCB?

The cost is determined by a range of factors, such as material expenses, manufacturing intricacies, and production scale. Precise costs must be assessed in accordance with particular requirements and manufacturing circumstances.

What are the temperature characteristics of Rogers 4450F PCB?

The material generally exhibits good temperature characteristics, but the specific temperature performance depends on application requirements and environmental conditions.

Can Rogers 4450F PCB be customized?

Yes, Rogers 4450F PCB can be customized according to specific requirements to meet the needs of different applications.

Why Are Rogers 4450F PCBs the Cornerstone in Electronics Packaging?

Rogers 4450F PCBs play a foundational role in the field of electronics packaging for the following reasons:

Outstanding High-Frequency Performance: Rogers 4450F PCBs exhibit exceptional high-frequency performance, making them excel in radio frequency (RF) and microwave applications, providing an ideal solution for high-frequency electronic packaging.

Low Loss: 4450F PCBs feature low-loss characteristics, aiding in minimizing energy loss during signal transmission, thereby maintaining signal clarity and strength.

Dimensional Stability: Rogers 4450F PCBs demonstrate excellent dimensional stability, with minimal physical dimension changes even under different temperatures and environmental conditions, ensuring the reliability of electronics packaging.

Precise Control of Dielectric Constant: The material allows for precise control of the dielectric constant, contributing to design consistency and performance.

Suitability for Multilayer Designs: Rogers 4450F PCBs are suitable for multilayer designs, meeting the requirements for multilayer circuits in complex electronic packaging.

Overall, with its outstanding performance in high-frequency capabilities, low loss, dimensional stability, and precise control of the dielectric constant, Rogers 4450F PCBs have become the cornerstone in electronics packaging, supporting the reliable operation of various advanced electronic devices and systems.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier