What is Rogers 4360G2 PCB?

Rogers 4360G2 PCB Manufacturer,Rogers 4360G2 PCB is an advanced laminate material designed for high-frequency applications, offering exceptional electrical performance and reliability. With a low dielectric constant and dissipation factor, it ensures minimal signal loss and superior signal integrity. This substrate features excellent thermal conductivity and dimensional stability, making it suitable for harsh operating conditions. Rogers 4360G2 PCB is widely utilized in aerospace, defense, and telecommunications industries, where high-speed data transmission is crucial. Its robust construction and precise material properties enable the development of compact and efficient electronic circuits, ensuring optimal performance and durability in demanding environments.

RO4360G2 laminates are the first high dielectric constant (Dk) thermoset laminate that can be processed similar to FR-4. These materials are lead-free process capable and offer better rigidity for improved processability in multi-layer board constructions, while reducing material and fabrication costs. RO4360G2 laminates can be paired with RO4400™ series prepreg and lower-Dk RO4000® laminate in multi-layer designs.

Features

- Dk of 6.15 +/- 0.15

- Low dissipation factor of 0.0038 at 10 GHz

- High thermal conductivity of 0.75 W/(m-K)

- Low Z-axis coefficient of thermal expansion at 28 ppm/°C

- High Tg greater than 280 °C TMA

Benefits

- Automated assembly compatible

- Plated through-hole reliability

- Environmentally friendly – lead free process compatible

- Efficient supply chain and short lead times makes for cost effective material option

Rogers 4360G2 is a high-frequency printed circuit board (PCB) material extensively utilized in the production of radio frequency (RF) and microwave circuits. Tailored for exceptional high-frequency performance, it excels in applications requiring minimal loss, superior signal fidelity, and stability. As a glass-reinforced polytetrafluoroethylene (PTFE) composite material, Rogers 4360G2 is specifically engineered to deliver excellent results in the high-frequency spectrum. Its widespread adoption in RF and microwave engineering underscores its efficacy in meeting the demands of advanced electronic applications.

This PCB material is typically employed in the fabrication of antennas, filters, amplifiers, mixers, and other high-frequency circuits. Due to its low loss, outstanding dielectric constant stability, and mechanical properties, Rogers 4360G2 is considered a high-performance material for RF/microwave PCB applications.

In summary, Rogers 4360G2 is a circuit board material specifically designed for high-frequency applications, offering superior performance to meet the stringent requirements of applications demanding high-frequency signal performance and stability.

Rogers 4360G2 PCB Manufacturer

What Functions Does Rogers 4360G2 PCB Serve?

The Rogers 4360G2 PCB is primarily utilized in the manufacturing of high-frequency electronic circuits, serving the following functions:

High-Frequency Signal Transmission: Due to the low dielectric constant and low loss characteristics of Rogers 4360G2, it efficiently transmits high-frequency signals, making it suitable for radio frequency (RF) and microwave circuits.

Low Signal Loss: The design of the 4360G2 PCB material aims to minimize signal loss, ensuring minimal energy loss during the transmission of signals at high frequencies.

Stability: The material exhibits stability across a wide frequency range, contributing to consistent circuit performance at different frequencies.

RF and Microwave Applications: The 4360G2 PCB finds extensive use in RF and microwave engineering, including applications in communication systems, radar systems, and satellite communication. It fulfills the requirements for superior high-frequency performance and stability in these specialized fields.

Glass Reinforcement: Being composed of a composite material reinforced with glass fibers and polytetrafluoroethylene (PTFE), it exhibits robust physical strength and durability, making it well-suited for the fabrication of intricate electronic devices.

In summary, the Rogers 4360G2 PCB plays a crucial role in high-frequency electronic applications, providing reliable electrical performance and meeting the requirements for signal quality and stability in demanding scenarios.

| Surface Resistivity | Typical Value | Direction | Unit | Condition | Test Method |

| Dielectric Constant,e,

(Process Specification) |

6.15 ± 0.15 | Z | 10 GHz/23°C | IPC-TM-650

2.5.5.5Clamped Stripline |

|

| 2.5 GHz/23°C | |||||

| Dissipation Factor | 0.0038 | Z | 10 GHz/23°C | IPC-TM-650, 2.5.5.5 | |

| Thermal Conductivity | 0.75 | W/m/K | 50°C | ASTM D-5470 | |

| Volume Resistivity | 4.0 x 10¹³ | Ω•cm | Elevated T | IPC-TM-650, 2.5.17.1 | |

| Surface Resistivity | 9.0 x 10¹² | Ω | Elevated T | IPC-TM-650, 2.5.17.1 | |

| Electrical Strength | 784 | Z | V/mil | IPC-TM-650, 2.5.6.2 | |

| Tensile Strength | 131 (19)

97 (14) |

X

Y |

MPa (kpsi) | 40 hrs 50%RH/23°C | ASTM D638 |

| Flexural Strength | 213 (31)

145 (21) |

X

Y |

MPa (kpsi) | 40 hrs 50%RH/23°C | IPC-TM-650, 2.4.4 |

| Coefficient of Thermal

Expansion |

13 | X | ppm/°C | -50°C to 288°C

After Replicated Heat Cycle |

IPC-TM-650, 2.1.41 |

| 14 | Y | ||||

| 28 | Z | ||||

| Tg | >280 | °C TMA | N/A | IPC-TM-650 2.4.24.3 | |

| Td | 407°C | °C | N/A | ASTM D3850 using TGA | |

| T288 | >30 | Z | min | 30 min / 125°C

Prebake |

IPC-TM-650

2.4.24.1 |

| Moisture Absorption | 0.08 | % | 50°C/48hr | IPC-TM-650 2.6.2.1 ASTM D570 | |

| Thermal Coefficient of e | -131 @ 10 GHz | ppm/°C | 50°C to 150°C | IPC-TM-650, 2.5.5.5 | |

| Density | 2.16 | gm/cm3 | RT | ASTM D792 | |

| [4] Copper Peel Strength | 5.2 (0.91) | pli (N/mm) | Condition B | IPC-TM-650 2.4.8 | |

| Flammability | V-0 | UL94 File

QMTS2.E102763 |

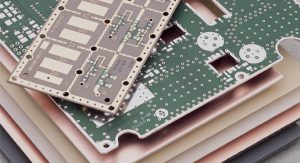

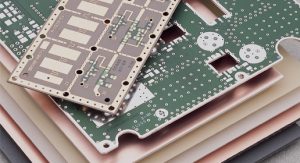

What Are the Different Types of Rogers 4360G2 PCB?

Rogers 4360G2 PCB comes in various types

Single-layer board: The simplest type of Rogers 4360G2 PCB, consisting of a single layer of substrate, suitable for basic high-frequency applications.

Double-layer board: Involves two layers of substrate, allowing for more complex circuit designs and providing additional layout and connectivity options.

Multi-layer board: Incorporates multiple layers of substrate, often used in more intricate electronic devices, accommodating more circuit components and offering higher integration.

Rigid and flexible boards: Depending on the application requirements, Rogers 4360G2 PCB can be designed as a rigid board (Rigid PCB) or a flexible board (Flexible PCB) to meet different mechanical demands and shapes.

Specialized boards for high-frequency applications: Designed specifically for particular high-frequency applications, these boards may include customized electrical characteristics to meet specific requirements.

These types of Rogers 4360G2 PCB can be customized according to project requirements to meet the diverse needs of different applications. When selecting the appropriate type, factors such as circuit complexity, frequency requirements, mechanical design, among others, are typically taken into consideration.

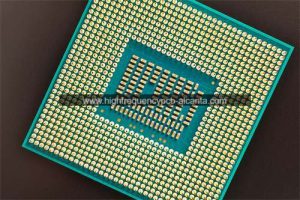

How Does Rogers 4360G2 PCB Interact with IC Packages?

The interaction between Rogers 4360G2 PCB and integrated circuit (IC) packages involves several aspects:

Thermal Performance: Rogers 4360G2 PCB typically exhibits good thermal conductivity, which is crucial when used with IC packages. Efficient thermal conductivity facilitates the transfer of heat generated by the integrated circuit to the PCB surface, enabling effective dissipation to the surrounding environment, typically accomplished through the use of a heat sink.

Electrical Connection: Connections between the PCB circuit and the IC package are formed using soldering or alternative connection methods.. Rogers 4360G2 PCB provides reliable electrical performance, ensuring the stability and reliability of signal transmission.

High-Frequency Characteristics: Due to its design for high-frequency applications, Rogers 4360G2 PCB can support high-frequency signal transmission, which is essential for wireless communication and other high-frequency electronic devices that may be present in IC packages.

Package Layout: Rogers 4360G2 PCB can be customized to accommodate different package layouts and sizes. This flexibility allows it to match various types and sizes of IC packages.

Noise and Interference Control: Through proper design and layout, Rogers 4360G2 PCB helps control noise and interference that may occur during signal transmission, ensuring the performance of the IC package.

Overall, Rogers 4360G2 PCB collaborates with IC packages by providing good thermal performance, reliable electrical connections, high-frequency characteristics, and flexible design, ensuring the stability and performance of electronic devices.

What Sets Rogers 4360G2 PCB Apart from Traditional PCBs?

Rogers 4360G2 PCB stands out from traditional PCBs due to the following features:

High-Frequency Performance: Specifically designed for high-frequency applications, Rogers 4360G2 PCB excels in high-frequency performance. Its low dielectric constant and low loss characteristics make it well-suited for radio frequency (RF) and microwave circuits, making it more suitable than traditional PCBs for applications that demand precise signal transmission.

Thermal Conductivity: Thanks to its unique material properties, Rogers 4360G2 PCB exhibits excellent thermal conductivity. Efficient heat transfer and dissipation are advantageous in the context of integrated circuits, actively promoting the stability of electronic devices.

Material Composition: Rogers 4360G2 employs a composite material composed of polytetrafluoroethylene (PTFE) reinforced with glass fibers.This material combination provides the PCB with robust physical strength, making it more durable and suitable for complex electronic devices compared to traditional PCBs.

Specific Application Requirements: 4360G2 PCBs are often customized to meet the specific requirements of applications such as high-frequency communication, radar systems, and satellite communication. This customization allows it to flexibly adapt to various high-demand electronic applications.

Manufacturing Complexity: Due to its focus on high performance and specific applications, Rogers 4360G2 PCB may involve greater manufacturing and processing complexity compared to traditional PCBs, requiring a higher level of manufacturing expertise.

In summary, Rogers 4360G2 PCB distinguishes itself through superior high-frequency and thermal performance, unique material composition, customization for specific applications, and potential manufacturing intricacies, making it a standout choice for certain electronic engineering applications.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings |

| 0.008” (0.203mm) +/- 0.0007”

0.016” (0.406mm) +/- 0.0015” 0.020” (0.508mm) +/- 0.0015” 0.024” (0.610mm) +/- 0.0015” 0.032” (0.813mm) +/- 0.0020” 0.060” (1.524mm) +/- 0.0040” *Additional non-standard thicknesses available from 0.008” – 0.060” in increments of 0.004” |

24” X 18” (610 X 457mm)

24” X 21” (610 X 533mm) 24” X 36” (610 X 915 mm) 48” X 36” (1219 X 915 mm) *Additional panel size available |

Electrodeposited Copper Foil

½ oz. (18µm) HH/HH 1 oz. (35µm) H1/H1 *Additional claddings, such as heavy metal, resistive foil and unclad are available |

What Constitutes the Main Structure and Production Technologies of Rogers 4360G2 PCB?

The main structure and production technologies of Rogers 4360G2 PCB include the following aspects:

Substrate: The primary substrate of Rogers 4360G2 PCB is composed of a composite material reinforced with glass fibers and polytetrafluoroethylene (PTFE). This material provides the PCB with good physical strength and heat resistance.

Conductive Layers: Copper foil is commonly used for the conductive layers of the PCB. The copper foil is patterned through processes like chemical etching or mechanical machining to form the circuit pattern for current and signal transmission.

Lamination Structure: Rogers 4360G2 PCBs are typically multi-layered, consisting of multiple substrate layers and conductive layers. These layers are laminated together through a lamination process to form a complete circuit board.

Solder Mask and Plating Layers: The PCB may include solder mask layers to cover the circuits, preventing short circuits and corrosion. Additionally, plating layers may be added to areas requiring soldering to enhance soldering performance.

Printing: Circuit patterns on the PCB are usually created through printing techniques, where conductive materials are applied to the substrate surface through methods like screen printing or other printing processes.

In the manufacturing journey of Rogers 4360G2 PCB, various components undergo a sequence of production steps, encompassing chemical treatments, lamination, cutting, and soldering, culminating in the creation of the ultimate circuit board. Each stage demands meticulous precision and stringent control to guarantee that the end product aligns with the standards of high performance and quality.

FAQs

What is Rogers 4360G2 PCB?

Rogers 4360G2 PCB is a type of high-frequency printed circuit board (PCB) material, mainly used in radio frequency (RF) and microwave circuits, boasting excellent high-frequency performance.

How does Rogers 4360G2 PCB differ from traditional PCBs?

Compared to traditional PCBs, Rogers 4360G2 PCB offers superior high-frequency and thermal performance, along with a unique glass-reinforced polytetrafluoroethylene (PTFE) composite material, making it stand out in specific applications.

What applications is Rogers 4360G2 PCB suitable for?

4360G2 PCB is suitable for high-frequency electronic applications, including but not limited to communication systems, radar systems, satellite communication, and other areas requiring stable signal transmission.

What are the manufacturing steps for Rogers 4360G2 PCB?

The manufacturing process of Rogers 4360G2 PCB involves multiple steps, including chemical treatments, lamination, cutting, and soldering, ensuring the final product meets high-performance and quality standards.

How many layers does Rogers 4360G2 PCB have?

Rogers 4360G2 PCB is typically a multi-layered structure, and the specific number of layers can be customized based on project requirements.

What are the advantages of Rogers 4360G2 PCB?

The advantages of 4360G2 PCB include outstanding high-frequency and thermal performance, special composite materials, and customization for specific applications.

Conclusion

Rogers 4360G2 PCB, as a high-frequency printed circuit board material, demonstrates outstanding performance and flexibility in the field of electronics. Its special composition of glass-reinforced polytetrafluoroethylene (PTFE) composite material, superior high-frequency characteristics, and customization for specific applications have led to its widespread use in high-frequency electronic devices such as communication systems, radar systems, and satellite communication.

The complex manufacturing process of Rogers 4360G2 PCB, involving steps like chemical treatments, lamination, cutting, and soldering, demands high precision and control to ensure that the final product meets the standards of high performance and quality. In comparison to traditional PCBs, Rogers 4360G2 PCB expands possibilities in electronic engineering applications for high-frequency devices by offering exceptional high-frequency performance and unique material composition.

In summary, Rogers 4360G2 PCB provides a reliable and innovative solution for the high-frequency electronics field through its distinctive design and superior performance.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier