Whati s Rogers 4350B PCB?

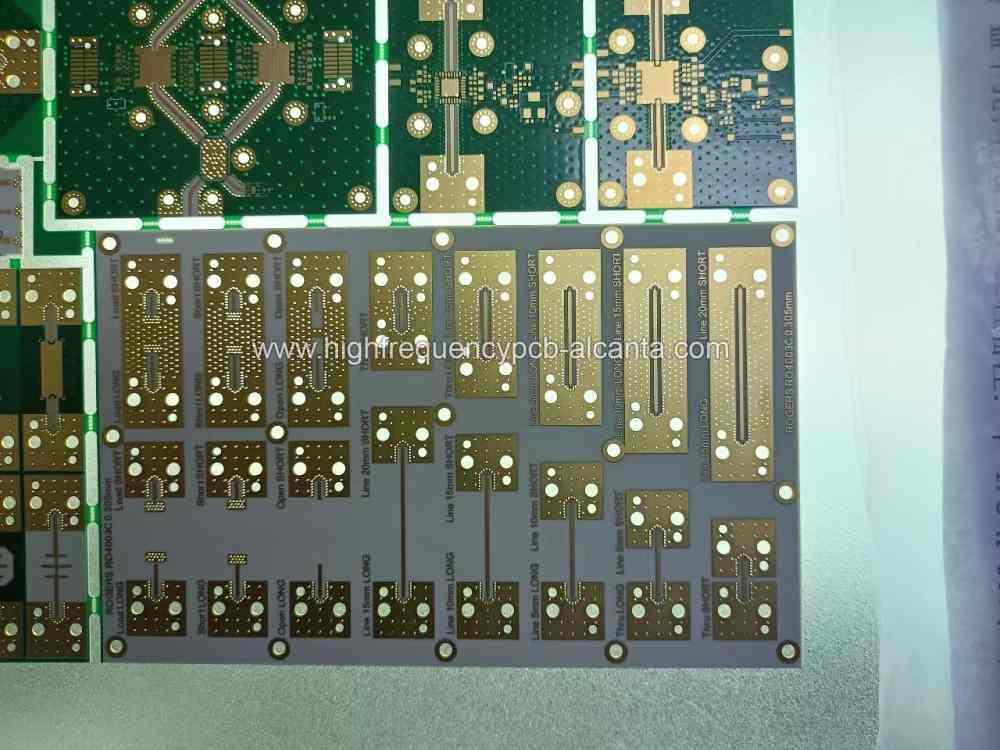

Rogers 4350B PCB Manufacturer,Rogers 4350B PCB is a high-performance laminate material tailored for demanding RF and microwave applications. Known for its exceptional electrical properties, including a low dielectric constant and loss tangent, it ensures efficient signal transmission with minimal loss. This substrate offers excellent dimensional stability and thermal conductivity, making it suitable for high-power and high-frequency circuits. Rogers 4350B PCB is widely used in aerospace, defense, and telecommunications industries, where reliability and performance are critical. Its advanced material composition and precise manufacturing processes enable the development of compact, high-density electronic assemblies with superior signal integrity and thermal management capabilities.

RO4350B laminates provide tight control on dielectric constant (Dk) and maintain low loss while utilizing the same processing method as standard epoxy/glass. Available at a fraction of the cost of conventional microwave laminates, RO4350B laminates do not require the special through-hole treatments or handling procedures as PTFE based materials. These materials are UL 94 V-0 rated for active devices and high power RF designs.

Features

- Dk of 3.48 +/- 0.05

- Dissipation factor of 0.0037 at 10 GHz

- Low Z-axis coefficient of thermal expansion at 32 ppm/°C

Benefits

- Processes like FR-4 at lower fabrication cost

- Competitively priced

- Excellent dimensional stability

Rogers 4350B is a type of high-frequency circuit board material belonging to the RO4350 series produced by Rogers Corporation. The RO4350 series comprises a composite material that incorporates glass-reinforced polytetrafluoroethylene (PTFE), showcasing outstanding high-frequency characteristics. Widely employed in radio frequency (RF) and microwave applications, this material plays a pivotal role in scenarios where superior high-frequency performance and stability are essential.

Rogers 4350B features low loss, stable dielectric constant, excellent dimensional stability, and good processing characteristics. It is suitable for applications with high demands on high-frequency performance, such as communication equipment, radar systems, antenna design, and more. The properties of this material enable the circuit board to deliver stable performance in high-frequency environments, minimizing signal attenuation and distortion.

In summary, Rogers 4350B PCB is a circuit board material designed specifically for high-frequency applications, suitable for communication and RF systems that require high performance and stability.

Rogers 4350B PCB Manufacturer

What Makes Rogers 4350B PCB Exceptional?

What makes Rogers 4350B PCB exceptional lies in its unique characteristics and performance. Here are some aspects that contribute to its outstanding features:

Exceptional High-Frequency Performance: Rogers 4350B PCB is specifically designed for high-frequency applications, showcasing excellent high-frequency performance. This makes it excel in radio frequency (RF) and microwave fields, contributing to stable, low-loss signal transmission.

Stable Dielectric Constant: The dielectric constant of this PCB material is highly stable, crucial for ensuring accurate signal transmission and maintaining circuit performance. A stable dielectric constant helps reduce signal distortion, enhancing system reliability.

Low Loss Characteristics: Rogers 4350B possesses low-loss characteristics, meaning it minimizes energy loss during signal transmission. This is critical for maintaining signal strength and quality, especially in high-frequency environments.

Dimensional Stability: The material exhibits excellent dimensional stability, maintaining the geometric shape of the circuit board even under varying temperature and humidity conditions. This ensures consistency and reliability in design.

Processing Performance: Rogers 4350B performs well during the manufacturing process, allowing manufacturers to relatively easily produce complex circuit boards. This enhances production efficiency and reduces manufacturing costs.

In summary, Rogers 4350B PCB stands out for its exceptional high-frequency performance, stable characteristics, and adaptability to diverse environmental conditions. It is well-suited for applications that demand high circuit performance.

| Surface Resistivity | Typical Value | Direction | Unit | Condition | Test Method |

| Dielectric Constant,e,

Process |

⁽¹⁾3.48 ± 0.05 | Z | — | 10 GHz/23℃ | IPC-TM-650 2.5.5.5

Clamped Stripline |

| ⁽²⁾Dielectric Constant,e,

Design |

3.66 | Z | — | 8 to 40 GHz | Differential Phase Length Method |

| Dissipation Factor,tan,d | 0.0037

0.0031 |

Z | — | 10 GHz/23℃

2.5 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of e, | +50 | Z | ppm/℃ | -50℃to 150C | IPC-TM-650 2.5.17.1 |

| Volume Resistivity | 1.2×10¹º | — | MΩ.cm | COND A | IPCTM-650

2.5.6.2 |

| Surface Resistivity | 5.7×10⁹ | — | MΩ | COND A | IPC 2.5.17.1 |

| Electrical Strength | 31.2

(780) |

Z | KV/mm (V/mil) | 0.51mm

(0.020) |

IPC 2.5.17.1 |

| Tensile Modulus | 16,767 (2,432)

14,153, (2,053) |

X Y | MPa (ksi) | RT | ASTM D638 |

| Tensile Strength | 203 (29.5)

130 (18.9) |

X Y | MPa(ksi) | RT | ASTM D638 |

| Flexural Strength | 255

(37) |

— | MPa (kpsi) | — | IPC-TM-650

2.4.4 |

| Dimensional Stability | <0.5 | X,Y | mm/m

(mils/inch) |

after etch

+E2/150℃ |

IPC-TM-650

2.4.39A |

| Coefficient of Thermal Expansion | 10

12 32 |

X Y Z | ppm/℃ | -55 to 288℃ | IPC-TM-650 2.4.41 |

| Tg | >280 | — | ℃TMA | A | IPC-TM-650

2.4.24.3 |

| Td | 390 | — | ℃TGA | ASTM D3850 | |

| Thermal Conductivity | 0.69 | — | W/m/ºK | 80℃ | ASTM C518 |

| Moisture Absorption | 0.06 | — | % | 48 hrs immersion

0.060″ sample Temperature 50℃ |

ASTM D570 |

| Density | 1.86 | — | 9/cm³ | 23℃ | ASTM D792 |

| Copper Peel Strength | 0.88

(5.0) |

— | N/mm

(pli) |

after solder float

1 oz.EDC Foil |

IPC-TM-650

2.4.8 |

| Flammability | ⁽³⁾V-0 | — | — | UL 94 | |

| Lead-Free ProcessCompatible | Yes | — | — | — |

What Defines Rogers 4350B PCB?

The characteristics that define Rogers 4350B PCB are primarily reflected in the following aspects:

Exceptional High-Frequency Performance: Rogers 4350B PCB is a circuit board material designed specifically for high-frequency applications, featuring outstanding high-frequency performance. In the radio frequency (RF) and microwave domains, it provides stable, low-loss signal transmission.

Stable Dielectric Constant: The dielectric constant of this PCB material is highly stable, critical for ensuring accurate signal transmission and maintaining circuit performance. This stability helps reduce signal distortion, enhancing system reliability.

Low Loss Characteristics: Rogers 4350B possesses low-loss characteristics, meaning it minimizes energy loss during signal transmission. This is crucial for maintaining signal strength and quality, especially in high-frequency environments.

Dimensional Stability: The material exhibits excellent dimensional stability, maintaining the geometric shape of the circuit board even under varying temperature and humidity conditions. This ensures consistency and reliability in design.

Processing Performance: Rogers 4350B performs well during the manufacturing process, allowing manufacturers to relatively easily produce complex circuit boards. This enhances production efficiency and reduces manufacturing costs.

In summary, Rogers 4350B PCB stands out for its exceptional high-frequency performance, stable characteristics, and adaptability to diverse environmental conditions. This makes it an ideal choice for applications that demand high circuit performance.

How Does Rogers 4350B PCB Function?

The functionality of Rogers 4350B PCB is primarily achieved through its material characteristics. Here are some key functions and principles of its operation:

High-Frequency Signal Transmission: Rogers 4350B PCB is specifically designed for high-frequency applications. Its material features low loss and a stable dielectric constant, facilitating the transmission of high-frequency signals in the circuit. This ensures reliable signal transmission in radio frequency (RF) and microwave systems.

Low Loss Characteristics: The material exhibits low-loss characteristics, minimizing energy loss during signal transmission. This is crucial for maintaining the strength and quality of signals, especially in high-frequency environments.

Stable Dielectric Constant: Rogers 4350B PCB has a highly stable dielectric constant, essential for ensuring the consistency and accurate transmission of signals. A stable dielectric constant helps reduce signal distortion and enhances overall system performance.

Dimensional Stability: The material possesses good dimensional stability, maintaining the geometric shape of the circuit board even under varying temperature and humidity conditions. This ensures design consistency and reliability.

Adaptability to Complex Environments: The characteristics of Rogers 4350B PCB enable it to adapt to diverse and complex environmental conditions, including temperature and humidity variations. This makes it well-suited for providing stable performance in a variety of applications.

In summary, Rogers 4350B PCB achieves reliable signal transmission and stable performance in high-frequency environments through its material’s high-frequency properties, low loss, stable dielectric constant, and dimensional stability.

What Are the Different Types of Rogers 4350B PCB?

There are primarily two main types of Rogers 4350B PCB, each with slightly different characteristics for specific applications. Here are the two main types:

Rogers 4350B: This is the standard Rogers 4350B PCB, featuring excellent high-frequency performance, low loss, and stable dielectric constant. It is suitable for various high-frequency applications, including communication devices, radar systems, and microwave equipment.

Rogers 4350B LoPro: This is a variant of the Rogers 4350B PCB series with lower thermal conductivity, designed for applications with stricter requirements on circuit board thickness. Rogers 4350B LoPro achieves lower thermal resistance by reducing the material’s thermal conductivity. Therefore, it is more suitable for scenarios with higher demands on thermal management.

Both types of PCB utilize Rogers 4350B material, providing excellent high-frequency performance and stability. However, the LoPro version optimizes thermal performance, making it more suitable for specific applications where circuit board thickness and thermal management requirements are more critical. The choice between the two types depends on specific design needs and application scenarios.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings |

| RO4350B:

0.004” (0.10mm) +/- 0.0007” 0.0066” (0.17mm) +/- 0.0007” 0.010” (0.25mm) +/- 0.0010” 0.020” (0.51mm) +/- 0.0015” 0.030” (0.76mm) +/- 0.0020” 0.060” (1.52mm) +/- 0.0040” |

24” X 18” (610 X 457 mm)

24” X 21” (610 X 533 mm) 24” X 36” (610 X 915 mm) 48” X 36” (1219 X 915 mm) *Additional panel sizes available |

Electrodeposited Copper Foil

½ oz. (18μm) HH/HH 1 oz. (35μm) H1/H1 *Additional cladding weights are available |

How Does Rogers 4350B PCB Differ from Conventional PCBs?

Rogers 4350B PCB differs significantly from conventional PCBs, primarily in terms of materials and performance:

Material Characteristics: Rogers 4350B PCB uses a composite material of glass-reinforced polytetrafluoroethylene (PTFE), while conventional PCBs often employ glass fiber and epoxy resin. The material of Rogers 4350B exhibits excellent high-frequency performance, stable dielectric constant, and low loss, making it excel in high-frequency applications.

High-Frequency Performance: Rogers 4350B PCB is designed for high-frequency applications, featuring outstanding high-frequency performance that ensures stable signal transmission in radio frequency (RF) and microwave environments. In contrast, conventional PCBs may experience higher signal attenuation and distortion under high-frequency conditions.

Stability: Rogers 4350B PCB possesses a stable dielectric constant and dimensional stability, crucial for ensuring accurate signal transmission and circuit consistency. The performance of conventional PCBs may degrade under different temperature and humidity conditions.

Specialized Applications: Rogers 4350B PCB is primarily used in fields that demand high-frequency performance, such as communication devices, radar systems, and microwave equipment. Conventional PCBs are more commonly used in general electronic devices and applications.

In summary, Rogers 4350B PCB excels in high-frequency performance and stability, making it more suitable for specific high-frequency applications, while conventional PCBs are more commonly found in general circuit board manufacturing. The choice between the two depends on specific design requirements and application scenarios.

What Constitutes the Main Structure and Production Technologies of Rogers 4350B PCB?

The main structure and production technologies of Rogers 4350B PCB include the following aspects:

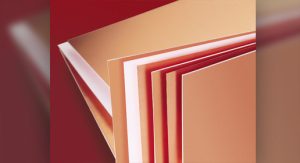

Substrate Material: The primary material of Rogers 4350B PCB is a special composite material, typically glass-reinforced polytetrafluoroethylene (PTFE). This material provides the PCB with excellent high-frequency performance and stability.

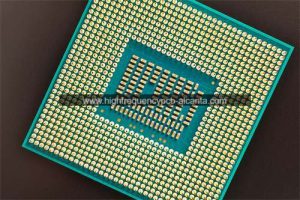

Conductive Layers: The conductive layers of the PCB are usually formed by covering the substrate surface with conductive materials, such as copper, to create circuit paths. These conductive layers constitute the connections between electronic components.

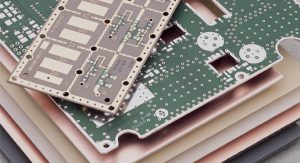

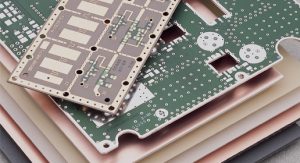

Layered Structure: Rogers 4350B PCB is typically a multilayer board, with each layer containing conductive and insulating layers. These layers are bonded together through a lamination process to form a complete circuit board.

Special Layer Processing: During the PCB manufacturing process, some layers may require special processing, such as microstrip line fabrication and impedance control. Treating these special layers often involves highly precise production techniques.

Cutting and Shaping: After the completion of PCB manufacturing, it is necessary to tailor and sculpt it in accordance with the design specifications. This step may encompass techniques like CNC machining or laser cutting, ensuring that the circuit board aligns precisely with the intended design parameters.

Drilling and Plating: Component installation on the PCB usually requires drilling. In this step, drilled holes are coated to provide conductivity, and an electroplating process is employed to ensure reliable connections.

In summary, the main structure of Rogers 4350B PCB includes substrate material, conductive layers, and a layered structure. During the manufacturing process, a variety of cutting-edge technologies are employed to ensure the PCB’s performance and reliability. These encompass lamination techniques, precision microfabrication processes, and electroplating methods.

What are the FAQs About Rogers 4350B PCB?

What is Rogers 4350B PCB?

Rogers 4350B PCB is a high-frequency circuit board material belonging to the RO4350 series produced by Rogers Corporation. It possesses excellent high-frequency performance and stability, widely used in radio frequency (RF) and microwave applications.

What are the characteristics of Rogers 4350B PCB?

Rogers 4350B PCB features outstanding high-frequency performance, stable dielectric constant, low loss, and good dimensional stability. It is suitable for applications that demand high-frequency performance.

How does Rogers 4350B PCB differ from conventional PCBs?

Rogers 4350B PCB differs significantly from conventional PCBs in terms of materials, performance, especially in high-frequency performance, stability, and the choice of special materials.

What types of Rogers 4350B PCB are there?

Rogers 4350B PCB primarily has two main types, including the standard Rogers 4350B and Rogers 4350B LoPro. They differ in thermal resistance performance and circuit board thickness.

What is the production process of Rogers 4350B PCB?

The production process of Rogers 4350B PCB includes substrate material selection, conductive layer coverage, layered structure formation, special layer processing, cutting and shaping, drilling, and electroplating.

Which applications is Rogers 4350B PCB suitable for?

Rogers 4350B PCB is suitable for applications that require high-frequency performance and stability, such as communication devices, radar systems, and microwave equipment.

What are the advantages of Rogers 4350B PCB?

The advantages of Rogers 4350B PCB include outstanding high-frequency performance, stable characteristics, low loss, and the ability to adapt to diverse environmental conditions.

How Does Rogers 4350B PCB Shape the Future of Electronic Design?

Rogers 4350B PCB has positively shaped the future of electronic design in several key aspects:

Driving Innovation through High-Frequency Performance:

Rogers 4350B PCB, with its outstanding high-frequency performance, plays a crucial role in fields such as communication, radar, and wireless networks. This forms the foundation for innovation in high-frequency electronic devices, driving advancements in communication technology, radar systems, and related domains.

Expansion of Microwave Technology Applications:

Due to its excellent performance in the microwave frequency range, Rogers 4350B PCB extends beyond communication to areas like radar, antenna design, and other microwave technology domains. This expansion has propelled the widespread application of microwave technology in military, aerospace, and other sectors.

Enhanced Flexibility in Circuit Design:

Rogers 4350B PCB provides design flexibility to meet the requirements of complex circuit layouts. Its stable performance and low-loss characteristics empower designers to work more freely on circuit designs, supporting the creation of more intricate and advanced electronic devices.

Market Development Driven by High-Performance RF Devices:

Leveraging the high-frequency capabilities of Rogers 4350B PCB supports the manufacturing of high-performance RF devices. This has a positive impact on market development in areas such as wireless communication, satellite communication, fostering innovation in wireless technology.

Lightweight and Miniaturization of Electronic Products:

The high dimensional stability of Rogers 4350B PCB allows for finer circuit board designs, contributing to the lightweight and miniaturization of electronic products. This meets the ongoing pursuit of modern electronic devices for reduced volume and weight.

In summary, Rogers 4350B PCB, with its exceptional high-frequency performance, stability, and flexibility, has influenced the trajectory of electronic design. It has driven innovation and progress in communication, microwave technology, RF devices, and other related fields.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier