What is Rogers 4003C PCB?

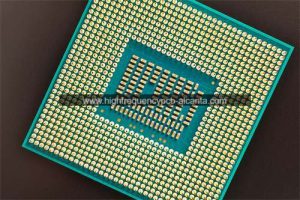

Rogers 4003C PCB Manufacturer,Rogers 4003C PCB is a high-frequency laminate material renowned for its exceptional electrical performance and reliability. With a low dielectric constant and loss tangent, it ensures minimal signal loss and high-speed transmission. This substrate offers excellent dimensional stability and thermal conductivity, making it ideal for demanding applications in aerospace, telecommunications, and automotive industries. Rogers 4003C PCB is engineered for precise impedance control and consistent performance over a wide frequency range. Its robust construction and superior material properties enable the development of advanced electronic circuits with enhanced efficiency and reliability, meeting the stringent requirements of modern electronic systems.

Offered in various configurations, RO4003C laminates utilize both 1080 and 1674 glass fabric styles with all configurations meeting the same laminate electrical performance specification. RO4003C laminates provide tight control on dielectric constant (Dk) and low loss while utilizing the same processing method as standard epoxy/glass but at a fraction of the cost of conventional microwave laminates. Unlike PTFE based microwave materials, no special through-hole treatments or handling procedures are required.

RO4003C materials are non-brominated and are not UL 94 V-0 rated. For applications or designs requiring a UL 94 V-0 flame rating, RO4835™ and RO4350B™ laminates do meet this requirement.

Features

- Dk of 3.38 +/- 0.05

- Dissipation factor of 0.0027 at 10 GHz

- Low Z-axis coefficient of thermal expansion at 46 ppm/°C

Benefits

- Ideal for multi-layer board (MLB) constructions

- Processes like FR-4 at lower fabrication cost

- Designed for performance sensitive, high volume applications

- Competitively priced

Rogers 4003C PCB is a special type of Printed Circuit Board (PCB) manufactured by Rogers Corporation. Rogers Corporation is a company specialized in producing high-performance materials, and they offer various advanced material solutions in the electronics industry, including those used in PCBs.

Rogers 4003C is a glass-reinforced Polyvinyl Chloride (FR-4) substrate, commonly employed in high-frequency applications such as Radio Frequency (RF) and microwave circuits. This PCB material exhibits low loss, stable dielectric constant, and low leakage characteristics, making it well-suited for circuit designs that require precise signal transmission and high-frequency performance.

In summary, Rogers 4003C PCB finds extensive use in wireless communication, satellite communication, radar systems, microwave communication, and other high-frequency electronic devices.

Rogers 4003C PCB Manufacturer

The Function of Substrates and the Ingenious Integration of Rogers 4003C

The function of substrates primarily involves providing mechanical support, electrical connections, and heat management. In electronic devices, especially in Printed Circuit Boards (PCBs), the choice of substrate is crucial for the overall system performance. Rogers 4003C is an excellent substrate material designed to meet the requirements of high-frequency electronic applications.

The ingenious integration of Rogers 4003C substrate is evident in several aspects:

High-Frequency Performance: Rogers 4003C features low loss, stable dielectric constant, and low leakage, making it excel in high-frequency electronic applications. It can effectively transmit precise signals and is suitable for Radio Frequency (RF) and microwave circuits.

Signal Integrity: Due to its excellent electrical properties, Rogers 4003C contributes to maintaining signal integrity. In high-frequency applications, accurate signal transmission is crucial for system performance, and this is an area where the substrate excels.

Heat Management: Electronic devices generate heat during operation, and effective heat management is crucial for maintaining system stability. Rogers 4003C has good thermal conductivity, aiding in the efficient dissipation and management of heat.

Mechanical Stability: Substrates need to provide mechanical support to ensure the secure installation of electronic components. Rogers 4003C exhibits excellent mechanical strength, contributing to the stability of the PCB structure.

In summary, the ingenious integration of Rogers 4003C makes it an ideal choice for many high-frequency electronic devices, providing superior performance and reliability to these systems.

| Surface Resistivity | Typical Value | Direction | Unit | Condition | Test Method |

| Dielectric Constant,e,

Process |

3.38±0.05 | Z | — | 10 GHz/23℃ | IPC-TM-650 2.5.5.5

Clamped Stripline |

| ⁽²⁾Dielectric Constant,e,

Design |

3.55 | Z | — | 8 to 40 GHz | Differential Phase Length Method |

| Dissipation Factor,tan,d | 0.0027

0.0021 |

Z | — | 10 GHz/23℃

2.5 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of e, | +40 | Z | ppm/℃ | -50℃to 150C | IPC-TM-650 2.5.17.1 |

| Volume Resistivity | 1.7×10¹º | — | MΩ.cm | COND A | IPCTM-650

2.5.6.2 |

| Surface Resistivity | 4.2×10⁹ | — | MΩ | COND A | IPC 2.5.17.1 |

| Electrical Strength | 31.2

(780) |

Z | KV/mm (V/mil) | 0.51mm

(0.020) |

IPC 2.5.17.1 |

| Tensile Modulus | 19,650(2,850)

19,450(2,821) |

X

Y |

MPa (ksi) | RT | ASTM D638 |

| Tensile Strength | 139(20.2)

100(14.5) |

X

Y |

MPa(ksi) | RT | ASTM D638 |

| Flexural Strength | 276

(40) |

— | MPa (kpsi) | — | IPC-TM-650

2.4.4 |

| Dimensional Stability | <0.3 | X,Y | mm/m

(mils/inch) |

after etch

+E2/150℃ |

IPC-TM-650

2.4.39A |

| Coefficient of Thermal Expansion | 11

14 46 |

X

Y Z |

ppm/℃ | -55 to 288℃ | IPC-TM-650 2.4.41 |

| Tg | >280 | — | ℃TMA | A | IPC-TM-650

2.4.24.3 |

| Td | 425 | — | ℃TGA | ASTM D3850 | |

| Thermal Conductivity | 0.71 | — | W/m/ºK | 80℃ | ASTM C518 |

| Moisture Absorption | 0.06 | — | % | 48 hrs immersion

0.060″ sample Temperature 50℃ |

ASTM D570 |

| Density | 1.79 | — | 9/cm³ | 23℃ | ASTM D792 |

| Copper Peel Strength | 1.05 (6.0) | — | N/mm

(pli) |

after solder float

1 oz.EDC Foil |

IPC-TM-650

2.4.8 |

| Flammability | N/A | — | — | UL 94 | |

| Lead-Free ProcessCompatible | Yes | — | — | — |

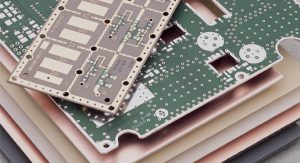

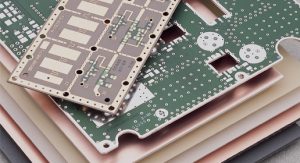

Different Types of Rogers 4003C PCB

Rogers 4003C PCB comes in various types, typically differentiated based on their thickness and specific performance requirements. Here are some common types of Rogers 4003C PCB:

Rogers 4003C Standard: This is the most common type, typically used for general high-frequency applications. It has balanced performance characteristics and is suitable for a wide range of electronic devices.

Rogers 4003C LoPro: This is a Low Profile board with a thinner thickness. It is designed for situations where there are restrictions on the thickness of the board, such as in some space-constrained devices.

Rogers 4003C Enhanced Thermal Performance: This type of PCB has enhanced thermal performance, suitable for applications that require better heat management. It performs well in high-temperature environments, helping prevent device overheating.

Rogers 4003C Immersion Silver: This is a PCB type that uses immersion silver technology, providing improved electrical and corrosion resistance properties. It is suitable for applications with high requirements for signal quality.

Rogers 4003C Lead-Free: This is a lead-free process PCB type, complying with environmental standards. It is suitable for the manufacturing of electronic devices that have environmental protection requirements.

These different types of Rogers 4003C PCB can be selected based on specific application requirements to meet performance and manufacturing needs in different scenarios.

Differences and Connections Between Substrates and Rogers 4003C PCB

Differences and Connections Between Substrates and Rogers 4003C PCB

Differences:

Definition:

Substrate: Typically refers to the material that supports electronic components and provides electrical connections. It can be the bottom material of a PCB, chip packaging material, or other materials used in electronic component manufacturing.

Rogers 4003C PCB: It is a specific type of printed circuit board that uses Rogers Corporation’s 4003C material. It is a type of substrate.

Scope:

Substrate: This is a broader term that can include various materials used to support and connect electronic components, not limited to printed circuit boards.

Rogers 4003C PCB: This is a specific type of substrate designed for high-frequency electronic applications.

Connections:

Purpose:

Substrate: In electronic manufacturing, substrates are used to provide support and electrical connections, including materials for PCBs, chip packaging bottoms, and more.

Rogers 4003C PCB: As a printed circuit board, the purpose of Rogers 4003C PCB is to support the installation of electronic components and provide electrical connections. It is also a specific type of substrate designed for high-frequency electronic applications.

Material Characteristics:

Substrate: Materials vary widely and can include organic substrates, glass fibers, ceramics, etc., depending on the application requirements.

Rogers 4003C PCB: It uses Rogers Corporation’s proprietary 4003C material, which has excellent high-frequency performance and is suitable for RF and microwave circuits.

In summary, substrate is a more generalized term that can encompass various materials used to support electronic components, while Rogers 4003C PCB is a specific type of substrate with special materials and design, tailored for specific high-frequency electronic applications.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings |

| RO4003C:

0.008” (0.203mm) +/- 0.0010” 0.012” (0.305mm) +/- 0.0010” 0.016” (0.406mm) +/- 0.0015” 0.020” (0.508mm) +/- 0.0015” 0.032” (0.813mm) +/- 0.0020” 0.060” (1.524mm) +/- 0.0040” |

24” X 18” (610 X 457 mm)

24” X 21” (610 X 533 mm) 24” X 36” (610 X 915 mm) 48” X 36” (1219 X 915 mm) *Additional panel sizes available |

Electrodeposited Copper Foil

½ oz. (18μm) HH/HH 1 oz. (35μm) H1/H1 *Additional cladding weights are available |

Comparison Between Rogers 4003C PCB and Conventional PCBs

Comparison Between Rogers 4003C PCB and Conventional PCBs

High-Frequency Performance:

Rogers 4003C PCB: Due to the use of special materials from Rogers Corporation, Rogers 4003C PCB excels in high-frequency performance. It has low loss, stable dielectric constant, and is suitable for Radio Frequency (RF) and microwave circuits.

Conventional PCB: Traditional PCB materials, such as FR-4, typically perform less effectively in high-frequency environments, as they may have higher losses and less stable dielectric characteristics.

Material Characteristics:

Rogers 4003C PCB: Utilizing a special glass-reinforced Polyvinyl Chloride (FR-4) substrate, it exhibits excellent thermal stability and high-frequency characteristics.

Conventional PCB: Traditional PCB materials may include FR-4, aluminum substrates, etc., with general performance suitable for low-frequency and general applications.

Price and Manufacturing Cost:

Rogers 4003C PCB: Due to the use of high-performance materials, it is relatively more expensive. Manufacturing and processing Rogers 4003C PCB may incur higher costs.

Conventional PCB: Traditional PCB materials are generally lower in cost, and the manufacturing process is relatively simpler, making them suitable for cost-sensitive applications.

Application Areas:

Rogers 4003C PCB: Primarily used in high-frequency electronic applications such as RF communication, microwave circuits, radar systems, where there are high demands for signal quality and high-frequency performance.

Conventional PCB: Conventional PCBs find widespread use in general electronic devices, such as consumer electronics, computer hardware, with relatively lower requirements for high-frequency performance.

Heat Management:

Rogers 4003C PCB: Possesses good thermal conductivity, suitable for applications with higher thermal management requirements.

Conventional PCB: Thermal management capability is generally moderate, suitable for standard temperature environments.

In summary, Rogers 4003C PCB offers advantages in high-frequency performance and specialized applications but comes with a relatively higher cost. Conventional PCBs are more suitable for applications with general performance requirements and cost-sensitive considerations. The choice between them depends on specific project requirements and budget considerations.

Structure and Production Technologies of Rogers 4003C PCB

Structure:

Substrate Layer: The foundation of Rogers 4003C PCB is a special substrate material, typically composed of glass-reinforced Polyvinyl Chloride (FR-4). The choice of this layer is crucial for the PCB’s electrical performance as it directly influences signal transmission and integrity.

Conductor Layer: Thin conductor layers, usually made of copper, are applied to the substrate. These conductors form the circuit patterns through which electrical currents flow. The layout and characteristics of these conductors are critical for ensuring signal quality, especially considering the high-frequency performance of Rogers 4003C.

Dielectric Layer: Positioned above the conductor layer, the dielectric layer isolates different circuit layers, preventing signal interference and crosstalk. Rogers 4003C is designed to ensure the stability and low-loss characteristics of this layer.

Outer Layer: PCBs may have multiple layers, and the outer layer typically consists of thin materials covering the dielectric layer. These outer layers play a crucial role in the mechanical stability and protection of the entire PCB.

Production Technologies:

Material Selection: The manufacturing of Rogers 4003C PCB begins with material selection. Special substrate materials, such as Rogers 4003C, are key to ensuring high-frequency performance.

Graphic Design: The design phase includes drawing the circuit diagram and laying out the conductor layers. For Rogers 4003C PCB, the design needs to consider the specific requirements of high-frequency signals.

Chemical Processing: This involves the etching process of the conductor layer, removing unwanted copper through chemical methods to form the circuit patterns.

Lamination: Different layers of the PCB are combined through the lamination process. During this process, materials are compressed together, and high temperature and pressure are applied to bond them into a cohesive whole.

Drilling and Punching: Drilling is used to create through-holes connecting different layers, while punching is used to create holes for external connections and component mounting.

Surface Treatment: This includes coating with outer layer materials, printing identifiers, and performing final surface treatments to enhance corrosion resistance and solderability.

In summary, the structure and production technologies of Rogers 4003C PCB are carefully designed to ensure superior performance and reliability in high-frequency applications.

FAQs

What are the differences between Rogers 4003C PCB and conventional PCBs?

Rogers 4003C PCB is a type of printed circuit board designed specifically for high-frequency applications, using a special substrate material of glass-reinforced Polyvinyl Chloride (FR-4). In comparison to conventional PCBs, it offers superior high-frequency performance, suitable for RF and microwave circuits.

What applications is Rogers 4003C PCB suitable for?

Rogers 4003C PCB is primarily used in high-frequency electronic applications, including RF communication, microwave circuits, radar systems, etc. Due to its excellent high-frequency performance, it finds widespread use in areas requiring precise signal transmission and low signal loss.

Is the manufacturing cost of Rogers 4003C PCB relatively high?

Yes, the manufacturing cost of Rogers 4003C PCB is generally higher compared to some traditional PCB materials. This is because it utilizes high-performance materials designed specifically for high-frequency applications.

What are the advantages of Rogers 4003C PCB?

The advantages of Rogers 4003C PCB include outstanding high-frequency performance, stable dielectric characteristics, low signal loss, and effective heat management. It is suitable for applications where high signal quality and high-frequency performance are essential.

Is Rogers 4003C PCB suitable for low-frequency applications?

Although Rogers 4003C PCB is primarily intended for high-frequency applications, it can also be applied in certain low-frequency scenarios where superior signal quality is required. Nonetheless, cost considerations may influence its suitability in such applications.

Is Rogers 4003C PCB environmentally friendly?

Rogers 4003C PCB itself does not have specific environmental certifications, but due to its application in specialized areas, it is often required to meet relevant environmental standards. Manufacturers may provide information on the environmental aspects of the materials used.

Conclusion

In conclusion, Rogers 4003C PCB, designed specifically for high-frequency applications, demonstrates outstanding performance in areas such as RF, microwave circuits, and other fields that demand high signal transmission and stability. Its unique substrate material, excellent high-frequency characteristics, and effective heat management make it an indispensable component in many high-tech applications.

However, it is important to note that while Rogers 4003C PCB can also perform well in certain low-frequency applications with stringent signal quality requirements, the consideration of its relatively higher manufacturing cost is crucial. In practical applications, the selection should be based on a comprehensive assessment of project requirements, budget constraints, and performance criteria, ensuring the optimal balance between performance and cost-effectiveness. Overall, Rogers 4003C PCB excels in meeting the demands of high-frequency electronic applications, contributing to the reliable foundation of modern electronic technology.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier