What is Rogers 3006 PCB?

RO3006 advanced circuit materials provide a stable dielectric constant (Dk) over a range of temperatures. This stability eliminates the step change in Dk that occurs for PTFE glass materials near room temperature.

Features

- Dk of 6.15 +/- .15

- Dissipation factor of .0020 at 10GHz

- Low X, Y and Z axis CTE of 17, 17 and 24 ppm/°C, respectively

Benefits

- ISO 9001 Certified

- Uniform mechanical properties with other RO3000™ Series laminates allows for multi-layer board designs

Could Rogers 3006 PCB, utilizing advanced Rogers material technology, truly provide outstanding electrical performance and reliability for electronic devices?

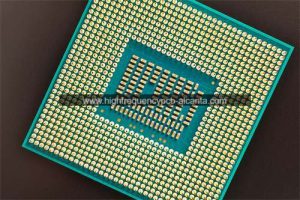

“Rogers 3006 PCB” denotes a distinctive printed circuit board (PCB) crafted by Rogers Corporation, a company dedicated to high-performance material solutions. Rogers provides a range of advanced materials tailored for the electronics sector, encompassing those integral to PCB fabrication. Rogers 3006 PCB employs specific materials from the company to meet exacting standards for high-frequency signal transmission, minimal loss, and stability. Widely employed in applications like wireless communication, radar systems, and antenna design, this PCB type meets the demands of precision circuits and steadfast performance. Overall, Rogers 3006 PCB signifies the fusion of cutting-edge materials and manufacturing techniques within the high-tech realm, establishing a dependable foundation for electronic devices.

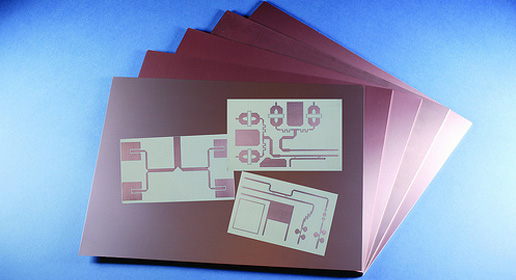

Rogers 3006 PCB Manufacturer

Do We Need to Revisit the Core Functions of Package Substrates?

Package substrates play a crucial role in electronic devices, making it essential to revisit their core functions to meet the demands of high-performance applications. Rogers 3006 PCB, a specialized printed circuit board, offers an opportunity to better comprehend the core functions of package substrates in electronic devices.

Rogers 3006 PCB boasts excellent electrical and mechanical properties, making it highly favored in high-frequency and high-performance applications. By utilizing this advanced PCB material, we can achieve an in-depth understanding in the following aspects:

Electrical Performance: Rogers 3006 PCB provides outstanding dielectric constant and low loss, aiding in reducing signal distortion and loss crucial for high-performance applications requiring higher frequencies and faster data transfer.

Thermal Management: In high-performance applications, thermal management is a critical consideration. Rogers 3006 PCB exhibits good thermal conductivity, assisting in efficiently dissipating heat generated by components, enhancing the overall system reliability and performance.

Mechanical Stability: Mechanical stability becomes particularly important in environments with high vibrations or extreme temperature conditions. The superior mechanical properties of Rogers 3006 PCB meet the requirements under such extreme conditions, ensuring device reliability.

Size and Weight: In certain high-performance applications, size and weight are key factors. The high integration and lightweight design of Rogers 3006 PCB contribute to meeting the requirements of these applications.

By delving into the performance characteristics of Rogers 3006 PCB, we can gain a better understanding of the crucial role package substrates play in high-performance applications, providing superior solutions for the design of future electronic devices.

| Property | Typical Value¹ | Direction | Unit | Condition | Test Method |

| Dielectric Constant,ε,

Process |

10.2±0.30 | Z | – | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline |

| ⁽²⁾Dielectric Constant,ε,

Design |

11.20 | Z | – | 8 GHz-40 GHz | Differential Phase Length Method |

| Dissipation Factor,tan δ | 0.0022 | Z | – | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of ε, | -395 | Z | ppm/C | 10 GHz -50 to 150℃ | IPC-TM-650 2.5.5.5 |

| Dimensional Stability | -0.35

-0.31 |

X

Y |

mm/m | COND A | IPCTM-650 2.2.4 |

| Volume Resistivity | 10⁵ | MΩ·cm | COND A | IPC 2.5.17.1 | |

| Surface Resistivity | 10⁵ | MΩ | COND A | IPC 2.5.17.1 | |

| Tensile Modulus | 1902

1934 |

X

Y |

MPa | 23℃ | ASTM D638 |

| Moisture Absorption | 0.05 | – | % | D48/50 | IPC-TM-650

2.6.2.1 |

| Specifc Heat | 0.8 | J/g/K | Calculated | ||

| Thermal Conductivity | 0.95 | – | W/m/K | 50℃ | ASTM D5470 |

| Coefficient of ThermalExpansion (-55 to 288C) | 13

11 16 |

X

Y Z |

ppm/C | 23℃/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | °CTGA | ASTM D3850 | ||

| Density | 2.8 | gm/cm³ | 23℃ | ASTM D792 | |

| Copper Peel Strength | 9.4 | lb/in | 1 oz.EDC After Solder Float | IPC-TM-2.4.8 | |

| Flammability | V-0 | UL 94 | |||

| Lead Free Process Compatible | YES |

How Does Rogers 3006 PCB Compare with Other Package Substrates?

Rogers 3006 is a high-performance PCB material known for its excellent electrical properties, especially in high-frequency applications. When comparing Rogers 3006 PCB with traditional package substrates like FR-4, it does offer several advantages, particularly in signal transmission and thermal stability.

Signal Transmission:

Low Loss Characteristics: Rogers 3006 has low dielectric loss, which means it exhibits minimal signal attenuation as compared to standard FR-4 substrates. This makes it highly suitable for high-frequency applications, such as RF (radio frequency) and microwave circuits, where signal integrity is crucial.

Stable Electrical Performance: The consistent dielectric constant of Rogers 3006 across a range of frequencies ensures predictable electrical performance, aiding in maintaining signal integrity.

Thermal Stability:

High Thermal Conductivity: Rogers 3006 has a higher thermal conductivity compared to FR-4. This property helps in dissipating heat efficiently, making it suitable for applications where thermal management is critical, such as in power amplifiers and high-power RF devices.

Low Thermal Expansion: The low coefficient of thermal expansion of Rogers 3006 contributes to its dimensional stability, reducing the risk of warping or delamination under temperature variations.

Real-World Examples:

Wireless Communication Devices: Rogers 3006 is commonly used in wireless communication devices, such as antennas, RF filters, and transceivers, where signal integrity and thermal stability are paramount. Its low loss characteristics ensure minimal signal attenuation, contributing to the overall performance of these devices.

High-Frequency PCBs: In applications where high-frequency signals are involved, like in radar systems or satellite communications, Rogers 3006 is preferred due to its ability to maintain signal integrity at elevated frequencies.

Power Amplifiers: In power amplifier circuits, where heat dissipation is crucial for maintaining performance and reliability, Rogers 3006’s high thermal conductivity helps in efficient heat transfer, preventing overheating of components.

It’s important to note that the choice of substrate depends on the specific requirements of the application. While Rogers 3006 offers advantages in certain aspects, it might be overkill for low-frequency or low-cost applications where traditional substrates like FR-4 can still perform adequately. Engineers and designers typically evaluate the trade-offs and choose the substrate that best meets the needs of their particular project.

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings |

| RO3006:

0.005″(0.13mm) +/-0.0005″ 0.010″(0.25mm) +/-0.0007″ 0.025″(0.64mm)+/-0.0010″ 0.050″(1.28mm)+/-0.0020″” |

RO3003

12″X 18″(305 X 457mm) 24″X 18″(610 X457mm)RO3003 0.005″ and 0.010″: 12″X 18″(305 X457mm) 24″X18″(610 X457mm) 24″X 21″(610 X533mm) |

RO3003:

Electrodeposited Copper Foil ½ oz.(18μm) (HH/HH) 1 oz.(35μm) (H1/H1) Rolled Copper Foil ½ oz.(18μm) (AH/AH) 1 oz. (35μm) (A1/A1) |

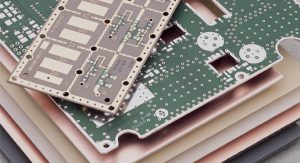

Is the Integration of Rogers 3006 PCB with IC Packaging Transformative?

Whether the integration of Rogers 3006 PCB with IC packaging technology is transformative depends on specific applications and design requirements. Rogers 3006 is a high-frequency circuit board material primarily used in wireless communication, radio frequency (RF), and microwave applications. The integration with IC packaging technology can potentially enhance performance and reliability in the following aspects:

Rogers 3006, with its low dielectric constant and low loss, excels in high-frequency and microwave ranges. Integrating it with IC packaging technology can improve the transmission performance of electrical signals, reducing signal distortion and losses.

High-performance ICs typically generate considerable heat, and Rogers 3006 PCB has good thermal conductivity. Effectively integrating ICs into this material can enhance thermal management, contributing to maintaining stable device performance.

Rogers 3006 PCBs are typically lightweight and thin, so combining them with IC packaging technology can enable compact designs. This can be advantageous in applications with strict size and weight requirements, such as mobile devices or aerospace systems.

Rogers 3006 material exhibits good chemical stability and mechanical strength, contributing to overall system reliability. In applications with stringent requirements for device lifespan and stability, this integration may significantly improve system reliability.

It’s important to note that the transformative effects of integration depend on specific application scenarios and design goals. In certain high-frequency, microwave, or RF applications, the combination of Rogers 3006 PCB with IC packaging technology may lead to substantial performance improvements. In standard low-frequency electronic devices, the impact may not be as significant. It is crucial during the design phase to meticulously evaluate system requirements, taking into account considerations like performance, cost, and reliability, to ascertain whether this integration approach stands out as the most optimal choice.

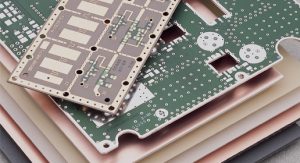

How Are Rogers 3006 PCBs Applied in Real-world Engineering?

Rogers 3006 is a high-frequency laminate material commonly used in the production of printed circuit boards (PCBs) for applications requiring exceptional performance at high frequencies, high speeds, and in challenging environmental conditions. While I don’t have specific case studies, I can provide you with general insights into how Rogers 3006 PCBs are applied in real-world engineering across various industries.

Telecommunications:

Rogers 3006 PCBs are widely used in the telecommunications industry for applications such as base station antennas, RF amplifiers, and high-frequency transceivers. The material’s low loss tangent and stable dielectric constant make it suitable for high-frequency signal transmission.

Aerospace and Defense:

In the aerospace and defense sector, Rogers 3006 PCBs find applications in radar systems, satellite communication equipment, and electronic warfare systems. The material’s high thermal stability and excellent electrical performance make it suitable for the demanding conditions of these applications.

Automotive Electronics:

Rogers 3006 is employed in automotive radar systems, collision avoidance systems, and other high-frequency applications within vehicles. Its ability to maintain signal integrity at high frequencies is crucial for the reliable performance of these systems.

Medical Devices:

Medical imaging equipment, such as MRI machines and high-frequency ultrasound devices, often require PCBs with excellent signal integrity. Rogers 3006 is chosen for its ability to handle high-frequency signals without significant loss.

Wireless Communication Devices:

Devices like high-frequency wireless routers and other communication equipment benefit from Rogers 3006 PCBs. The material’s consistent electrical properties contribute to signal reliability and overall performance.

Test and Measurement Equipment:

In the field of test and measurement, where precision and accuracy are paramount, Rogers 3006 PCBs are used in equipment such as network analyzers and spectrum analyzers. The material’s low loss characteristics contribute to the accuracy of measurements.

Rogers 3006 exhibits outstanding performance in high-frequency and high-speed applications due to its low dielectric loss, stable electrical properties, and excellent thermal stability. Its ability to maintain signal integrity, even in challenging environments with high temperatures, makes it a preferred choice for applications where reliability is crucial.

What Are the Frequently Asked Questions (FAQs) about Rogers 3006 PCB?

What is Rogers 3006 PCB?

Rogers 3006 is a high-frequency laminate material designed for printed circuit boards (PCBs). It belongs to the family of high-performance materials known for their excellent electrical and thermal properties.

What are the key characteristics of Rogers 3006 PCB?

Rogers 3006 PCBs exhibit low dielectric loss, high thermal conductivity, and stable electrical performance over a wide range of frequencies. These characteristics make it suitable for high-frequency applications.

What frequency range is suitable for Rogers 3006 PCB?

Rogers 3006 is optimized for high-frequency applications, typically ranging from RF (Radio Frequency) to microwave frequencies. It is well-suited for applications requiring signal integrity and low insertion loss.

What are the advantages of using Rogers 3006 PCB?

The main advantages include low loss tangent, consistent electrical performance, and good thermal stability. These features make it ideal for applications where signal integrity and reliability are critical.

In what applications is Rogers 3006 PCB commonly used?

Rogers 3006 PCBs find applications in high-frequency designs such as RF and microwave circuits, aerospace and defense systems, automotive radar systems, and other wireless communication devices.

Can Rogers 3006 PCB be used for high-power applications?

While Rogers 3006 offers good thermal conductivity, it is primarily designed for high-frequency applications where low loss is crucial. For high-power applications, other materials with specific thermal properties may be more suitable.

What is the temperature stability of Rogers 3006 PCB?

Rogers 3006 exhibits good temperature stability. It can handle a wide range of operating temperatures, making it suitable for applications where temperature variations are expected.

Is Rogers 3006 PCB compatible with standard PCB fabrication processes?

Yes, Rogers 3006 can be processed using standard PCB fabrication techniques. It is compatible with common methods such as etching, drilling, and soldering, making it convenient for manufacturers.

What is the cost implication of using Rogers 3006 PCB?

Rogers 3006 is a specialized material with enhanced performance, and as such, it may be more expensive compared to standard PCB materials. The cost will depend on factors such as board size, thickness, and order volume.

Are there any precautions to consider when working with Rogers 3006 PCB?

Users should follow the manufacturer’s guidelines for handling and processing Rogers 3006 PCBs. It’s important to consider specific requirements for fabrication and assembly to ensure optimal performance.

Can We Conclude That Rogers 3006 PCB is the Future of Package Substrate Technology?

The importance of Rogers 3006 PCB lies in its advanced technology, particularly in radio frequency (RF) and microwave applications.The exceptional dielectric performance, stability, and reliability of Rogers 3006 PCB render it well-suited for numerous high-frequency applications. However, given the dynamic nature of technological advancements, new materials and technologies may emerge in the future to either replace or further improve existing solutions.

In terms of potential future developments in package substrate technology, we can anticipate the following possibilities:

Higher frequencies and faster speeds: With the continuous increase in communication and computing demands, package substrate technology may evolve towards supporting higher frequencies and faster speeds.

Smaller size and lighter weight: As electronic devices trend towards miniaturization and lightweight design, future package substrates may become increasingly compact and lightweight.

Integrated multifunctionality: Future package substrates may emphasize greater multifunctionality, integrating more features and components to enhance system integration.

Greater energy efficiency: With growing attention to energy considerations, package substrate technology may evolve towards greater energy efficiency to meet sustainability demands.

Application of new materials: Future developments may introduce new materials to improve performance, reduce costs, or enhance other aspects of package substrate technology.

In conclusion, while the Rogers 3006 PCB currently excels in certain areas, it cannot be determined whether it will remain the future of package substrate technology. Future developments depend on technological innovation, market demands, and the evolution of other influencing factors.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier