What is Rogers 3003 PCB?

Rogers 3003 PCB Manufacturer,Rogers 3003 PCB is a high-quality printed circuit board material renowned for its excellent electrical properties and reliability in high-frequency applications. This laminate offers a low dielectric constant and minimal signal loss, making it ideal for RF and microwave circuits. Its stable dielectric constant over a wide frequency range ensures consistent performance, while its low dissipation factor contributes to high efficiency. Additionally, Rogers 3003 PCB has excellent mechanical stability and thermal conductivity, making it suitable for demanding environments in telecommunications, aerospace, and defense industries. These features make Rogers 3003 a preferred choice for designers seeking high-performance, durable PCBs.

RO3003 laminates offer excellent stability of dielectric constant (Dk) over various temperatures and frequencies. This stability also includes the elimination of the step change in Dk that typically occurs near room temperature with PTFE glass materials. This is ideal for applications including automotive radar (77 GHz), advanced driver assistance systems (ADAS) and 5G wireless infrastructure (mmWave).

Features

- Dk of 3.00 +/- .04

- Dissipation factor of .0010 at 10 GHz

- Low X, Y and Z axis CTE of 17, 16 and 25 ppm/°C, respectively

Benefits

- Low Dk loss allows for use in applications up to 77 GHz

- ISO 9001 certified

- Economical laminate pricing

Rogers 3003 PCB is a type of printed circuit board produced by Rogers Corporation. Rogers Corporation is a company specialized in manufacturing high-performance materials, and their products find applications in wireless communication, microwave technologies, and other high-frequency electronic devices.

Rogers 3003 is a high-frequency, low-dielectric constant (low Dk) material designed for applications requiring lower signal loss and enhanced performance. This material is commonly used in radio frequency (RF) and microwave circuits due to its excellent electrical properties, stability, and reliability. The characteristics of Rogers 3003 PCB make it an ideal choice, particularly in electronic devices that handle high-frequency signals, such as communication equipment and radar systems.

In summary, Rogers 3003 PCB is a printed circuit board material specifically designed for high-frequency electronic applications, aiming to provide outstanding performance and stability.

Rogers 3003 PCB Manufacturer

Can Rogers 3003 PCB Revolutionize Electronic Designs?

Rogers 3003 is a high-performance substrate widely used in radio frequency (RF) and microwave circuit designs. It possesses special properties that make it a noteworthy choice for certain applications.

Firstly, Rogers 3003 PCB is renowned for its excellent dielectric performance. This material exhibits low dielectric loss and a stable dielectric constant, making it well-suited for high-frequency applications such as RF antennas, microstrip lines, and microwave filters. This is crucial for designs that require accurate signal transmission and low energy loss.

Secondly, Rogers 3003 PCB also boasts good thermal stability and mechanical strength, enhancing its reliability in extreme environments. This proves advantageous for electronic device designs operating in high-temperature or high-vibration conditions.

Additionally, the design flexibility of Rogers 3003 PCB is worth noting. It can be tailored to meet various design requirements through different layer stack-ups and structural configurations, providing greater customization options.

However, it’s important to note that while Rogers 3003 PCB excels in certain aspects, the choice of material should be guided by specific application requirements. In some cases, alternative materials may also meet design specifications and offer more economical options.

Overall, Rogers 3003 PCB holds the potential to bring revolutionary changes to specific RF and microwave applications, providing electronic design engineers with additional tools and choices to meet the evolving demands of technology.

| Property | Typical Value¹ | Direction | Unit | Condition | Test Method |

| Dielectric Constant,ε,

Process |

3.00±0.04 | Z | – | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline |

| ⁽²⁾Dielectric Constant,ε,

Design |

3.00 | Z | – | 8 GHz-40 GHz | Differential Phase Length Method |

| Dissipation Factor,tan δ | 0.0010 | Z | – | 10 GHz 23℃ | IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of ε, | -3.00 | Z | ppm/C | 10 GHz -50 to 150℃ | IPC-TM-650 2.5.5.5 |

| Dimensional Stability | -0.06 0.07 | X

Y |

mm/m | COND A | IPCTM-650 2.2.4 |

| Volume Resistivity | 10⁷ | MΩ·cm | COND A | IPC 2.5.17.1 | |

| Surface Resistivity | 10⁷ | MΩ | COND A | IPC 2.5.17.1 | |

| Tensile Modulus | 930 823 | X

Y |

MPa | 23℃ | ASTM D638 |

| Moisture Absorption | 0.04 | – | % | D48/50 | IPC-TM-650

2.6.2.1 |

| Specifc Heat | 0.9 | J/g/K | Calculated | ||

| Thermal Conductivity | 0.50 | – | W/m/K | 50℃ | ASTM D5470 |

| Coefficient of ThermalExpansion (-55 to 288C) | 17

16 25 |

X

Y Z |

ppm/C | 23℃/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | °CTGA | ASTM D3850 | ||

| Density | 2.1 | gm/cm³ | 23℃ | ASTM D792 | |

| Copper Peel Strength | 12.7 | lb/in | 1 oz.EDC After Solder Float | IPC-TM-2.4.8 | |

| Flammability | V-0 | UL 94 | |||

| Lead Free Process Compatible | YES |

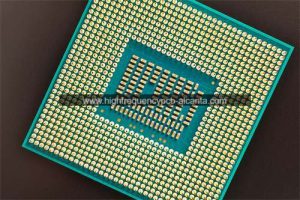

What Powers Package Substrates?

It seems like you’re looking for information on what powers package substrates in electronic systems. Package substrates play a crucial role in facilitating communication and power distribution within electronic components. Here’s an elaboration on this:

The power supply for package substrates in electronic systems originates from the electrical connections they establish for integrated circuits (ICs) and other electronic components. These substrates serve as crucial physical underpinnings, providing support and interconnections for the diverse elements within an electronic system. The primary functions of package substrates include:

Signal Transmission: Package substrates facilitate the conveyance of electrical signals among diverse components within an electronic system. This encompasses the transmission of signals between the central processing unit (CPU), memory modules, and various integrated circuits.

Power Distribution: Package substrates help distribute power to the various components within the electronic system. They establish routes for the transmission of electrical power from the source to individual circuits, guaranteeing that each component receives the required power to operate effectively.

Heat Dissipation: Numerous package substrates incorporate features that enhance thermal dissipation. Electronic components generate heat during operation, and efficient heat dissipation is essential to prevent overheating and maintain the reliability of the system. Package substrates may include thermal vias, pads, or other structures to dissipate heat.

Mechanical Support: Package substrates offer mechanical support for the integrated circuits and other electronic components. They help protect the delicate circuitry from physical damage, vibrations, and other external factors that could impact the performance of the system.

Form Factor and Integration: Package substrates contribute to the overall form factor and integration of electronic devices. They allow for the compact and organized arrangement of components, contributing to the miniaturization and efficiency of electronic systems.

The power within package substrates is derived from the external power source connected to the electronic system, such as a power supply unit or a battery. The package substrates, in turn, facilitate the distribution of this power to the various components and ensure the smooth functioning of the entire system.

How Does Rogers 3003 PCB Enhance Functionality?

The role of the Rogers 3003 PCB in enhancing functionality is primarily evident in its outstanding dielectric properties and high-frequency performance. In comparison to regular PCBs, the Rogers 3003 PCB significantly improves performance in the following aspects:

Excellent Dielectric Performance: Rogers 3003 PCB utilizes materials with superior dielectric characteristics, showcasing outstanding performance in high-frequency applications. Its low dielectric loss and stable dielectric constant contribute to reducing energy loss during signal transmission and enhancing signal integrity.

High-Frequency Performance: Due to its exceptional high-frequency performance, Rogers 3003 PCB excels in radio frequency (RF) and microwave applications. This is crucial for wireless communication, radar systems, and other high-frequency devices. Improved high-frequency performance ensures accurate signal transmission and reliability.

Reduced Signal Loss: Rogers 3003 PCB is designed to minimize signal loss during transmission. This means that energy loss is minimized as the signal travels through the PCB, contributing to maintaining signal strength and accuracy, thereby enhancing the overall system performance.

Reliable Data Transmission: In applications demanding highly reliable data transmission, Rogers 3003 PCB provides a stable signal transmission environment. This is critical in fields where stringent requirements for data transfer quality exist, such as in communication equipment, satellite communication, and medical devices.

In summary, the Rogers 3003 PCB plays a crucial role in enhancing signal integrity, reducing losses, and ensuring reliable data transmission, particularly in applications with strict requirements for high-frequency performance and signal quality.

What Sets Rogers 3003 PCB Apart Among Package Substrates?

The uniqueness of Rogers 3003 PCB (Printed Circuit Board) among package substrates lies primarily in its distinctive material composition and design. In comparison to various other package substrates available in the market, Rogers 3003 excels in IC (Integrated Circuit) package technologies. Let’s delve into the diverse landscape of package substrates and explore how Rogers 3003 stands out, particularly in the realm of IC package technologies.

Firstly, one of the key distinctions of Rogers 3003 PCB is its unique material composition. It incorporates special coatings and substrates with outstanding electrical performance. This material combination provides excellent high-frequency performance, making it an ideal choice for high-frequency applications. High-frequency performance is crucial for many IC applications, especially in fields such as communication and radar systems.

Secondly, the unique design of Rogers 3003 is another standout feature. Its design takes into consideration critical factors such as signal integrity and electromagnetic compatibility. This design superiority contributes to excellent circuit layout and signal transmission, helping to reduce signal distortion and electromagnetic interference.

Furthermore, Rogers 3003 is renowned for its superior thermal stability and reliability. This is particularly essential for IC packaging, as some applications may require operation at higher temperatures, and the materials in Rogers 3003 can maintain stability in these challenging environments.

In summary, the uniqueness of Rogers 3003 PCB in terms of material composition and design sets it apart in the realm of IC package technologies. Its high-frequency performance, superior signal integrity and electromagnetic compatibility, along with exceptional thermal stability, make it a preferred choice for many high-performance applications.

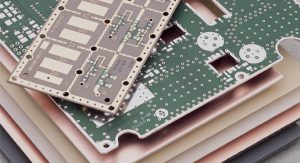

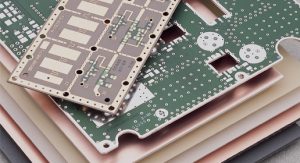

| Standard Thicknesses | Standard Panel Sizes | Standard Claddings |

| RO3003:

0.005″(0.13mm)+/-0.0005″ 0.010”(0.25mm)+/-0.0007″ 0.020”(0.51mm)+/-0.0010″ 0.030″(0.76mm)+/-0.0015″ 0.060″(1.52mm)+/-0.0030″ |

RO3003

12″X 18″(305 X 457mm) 24″X 18″(610 X457mm)RO3003 0.005″ and 0.010″: 12″X 18″(305 X457mm) 24″X18″(610 X457mm) 24″X 21″(610 X533mm) |

RO3003:

Electrodeposited Copper Foil ½ oz.(18μm) (HH/HH) 1 oz.(35μm) (H1/H1) Rolled Copper Foil ½ oz.(18μm) (AH/AH) 1 oz. (35μm) (A1/A1) |

Rogers 3003 PCB vs. Traditional PCB: Can it Bridge the Technological Gap?

The comparative analysis between Rogers 3003 PCB and traditional PCBs sheds light on the evolution of substrate technology. From standard Printed Wiring Boards (PWBs) and motherboards to innovative solutions like substrate-like PCBs and High-Density Interconnect (HDI) substrates, does Rogers 3003 hold a competitive edge in terms of signal fidelity and manufacturing flexibility?

Firstly, let’s focus on the characteristics of Rogers 3003 PCB. Rogers 3003 is a high-frequency material typically used in Radio Frequency (RF) and microwave applications. Compared to traditional PCBs, Rogers 3003 features lower loss, better dielectric constant, and stability. This makes it an ideal choice for handling high-frequency signals, especially in communication and radar systems.

In terms of signal fidelity, Rogers 3003 excels in the high-frequency range, providing better signal transmission performance. Its low-loss characteristics help reduce signal attenuation, thereby improving system performance and sensitivity. In traditional PCBs, signal distortion and attenuation issues may arise due to higher dielectric constant and losses.

Regarding manufacturing flexibility, Rogers 3003 also demonstrates certain advantages. As it is designed specifically for high frequencies, it can more easily meet the requirements of complex circuits and fine line widths. This is valuable for the trend in modern electronic devices towards smaller and more compact designs.

However, it’s important to note that Rogers 3003 PCB may be relatively higher in cost due to stricter material and manufacturing process requirements. Therefore, in choosing between Rogers 3003 and traditional PCBs, manufacturing costs may be a factor that needs to be balanced.

In conclusion, Rogers 3003 PCB holds a competitive advantage in handling high-frequency signals and meeting the demands of complex designs. However, in specific applications, factors such as manufacturing costs, design requirements, and performance criteria should be comprehensively considered to determine the most suitable substrate material.

What Lies at the Core of Rogers 3003 PCB’s Reliability?

The core of the reliability of Rogers 3003 PCB lies in its structure and manufacturing technologies. Let’s delve into it, from the core substrate structure to advanced fabrication methods such as improved High-Density Interconnect (HDI) technology and semi-additive processes, to uncover the secrets contributing to its unparalleled reliability and performance.

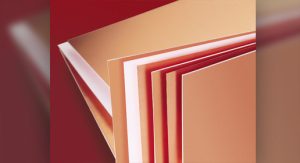

Firstly, the core substrate structure of Rogers 3003 PCB is crucial. The board utilizes special materials, typically polytetrafluoroethylene (PTFE), known for its excellent electrical properties and thermal stability. PTFE serves as an insulating material, effectively isolating circuit layers to prevent signal interference and leakage. This substrate also maintains low dielectric loss in high-frequency applications, enhancing signal transmission performance.

Secondly, High-Density Interconnect (HDI) technology plays a significant role in improving the performance of Rogers 3003 PCB. HDI technology allows for more connections and higher integration in limited space. By employing fine traces, small vias, and a multi-layered structure, HDI technology enhances signal transmission speed, reduces signal path length, and minimizes signal delay.

Semi-additive processes are also a contributing factor to the reliability of Rogers 3003 PCB. This process enables the incremental addition of copper layers during the PCB manufacturing process, as opposed to completing it in one step. This approach allows better control over the distribution and quality of copper, reducing manufacturing errors and improving the consistency and reliability of the circuit board.

In summary, the reliability of Rogers 3003 PCB is attributed to the application of advanced manufacturing technologies such as special substrate materials, HDI technology, and semi-additive processes. These technologies work synergistically, enabling the PCB to excel in high-frequency applications and other demanding environments, achieving outstanding reliability and performance.

FAQs About Rogers 3003 PCB: Answering Common Queries

What are the primary applications of Rogers 3003 PCB?

Rogers 3003 PCB excels in high-frequency and microwave applications, commonly used in communication devices, radar systems, satellite communications, and radio frequency (RF) electronic devices. Its superior dielectric constant and low-loss characteristics make it widely applicable in fields requiring high-performance and stable signal transmission.

Is Rogers 3003 PCB compatible with various systems?

Yes, Rogers 3003 PCB demonstrates excellent compatibility, suitable for a range of systems, including wireless communication systems, antenna designs, medical devices, and high-frequency electronic equipment. Its stable electrical performance makes it an ideal choice for many complex systems.

How is the thermal conductivity of Rogers 3003 PCB?

Rogers 3003 PCB boasts outstanding thermal conductivity, suitable for applications requiring efficient heat dissipation. This makes it particularly useful in designs where the circuit board needs to effectively dissipate heat, such as in radio frequency power amplifiers (RFPA) and high-power microwave devices.

What is the manufacturing cost of Rogers 3003 PCB?

The relatively higher material cost of Rogers 3003 PCB contributes to higher manufacturing costs. However, in applications where superior characteristics and stability are crucial, these properties often offset the associated costs.

What frequency range is Rogers 3003 PCB suitable for?

Rogers 3003 PCB is suitable for the high-frequency and microwave frequency range, typically performing well between 500 MHz and 40 GHz. This makes it an ideal choice for many wireless communication and RF applications.

What thickness and layer options are available for Rogers 3003 PCB?

Rogers 3003 PCB offers a variety of thickness and layer options to accommodate different design requirements. Common thickness ranges from 10 mils to 125 mils, and the number of layers can be customized based on specific design needs.

How environmentally adaptable is Rogers 3003 PCB?

Rogers 3003 PCB performs well in various environmental conditions, demonstrating good stability and durability.It sustains exceptional performance under extreme temperatures, humidity, and challenging chemical environments, rendering it suitable for a broad spectrum of applications.

Can Rogers 3003 PCB Redefine Electronic Engineering?

Can the Rogers 3003 PCB redefine electronic engineering? In summary, the Rogers 3003 PCB stands as a testament to the relentless pursuit of excellence in electronic engineering. As the demand for high-performance devices continues to soar, understanding the nuances of package substrates, especially the exceptional Rogers 3003, becomes imperative. Can this journey into the heart of advanced electronics reaffirm the pivotal role that package substrates play in shaping the future of technology?

Rogers 3003 PCB is renowned for its outstanding performance and characteristics, widely applied in high-frequency and high-performance electronic devices. Its excellent electrical properties, thermal stability, and adaptability to microwave and radiofrequency applications make it the preferred choice in many leading industries. Therefore, by delving into advanced packaging substrates like Rogers 3003, electronic engineers can better address the ever-evolving technological challenges.

This focus on packaging substrates and the continuous attitude towards innovation are expected to drive technological advancements in the field of electronic engineering. The Rogers 3003 PCB may set new standards for the design and manufacturing of future high-performance electronic devices, playing a crucial role in shaping the future of technology.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier