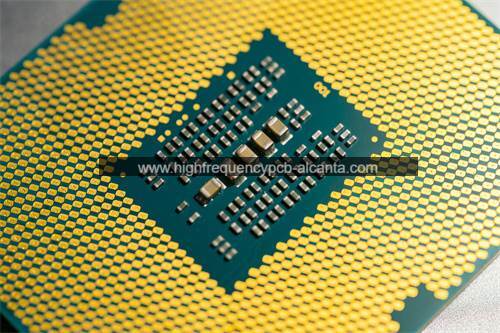

Mini Led PCB Substrate Manufacturer

Mini Led PCB Substrate Manufacturer,Mini LED PCB substrates are specialized printed circuit boards engineered to support the integration of Mini LEDs, compact yet powerful light-emitting diodes. These substrates serve as the foundation for various applications such as high-resolution displays, backlighting units, automotive lighting, and general illumination systems. Designed with precision and expertise, Mini LED PCB substrates prioritize efficient thermal management, ensuring optimal heat dissipation to maintain LED performance and longevity. They feature advanced materials like metal core PCBs or ceramic substrates, known for their high thermal conductivity, enabling effective heat dissipation even in demanding environments. With meticulous attention to detail, Mini LED PCB substrates are tailored to accommodate the specific requirements of Mini LED technology, including precise electrical routing, strategic component placement, and reliable soldering techniques. Through their robust construction and innovative design, Mini LED PCB substrates empower the development of cutting-edge lighting and display solutions, offering enhanced brightness, energy efficiency, and durability for a wide range of applications.

What is a Mini LED PCB Substrate?

A Mini LED PCB substrate is a printed circuit board (PCB) specifically designed to accommodate Mini LEDs. Mini LEDs are a type of light-emitting diode (LED) that is smaller in size compared to traditional LEDs, typically measuring less than 2mm in length.

The PCB substrate for Mini LEDs is engineered to provide electrical connections to the Mini LED chips, as well as to facilitate thermal management and mechanical support. These substrates often have specialized designs to ensure efficient heat dissipation, which is crucial for maintaining the performance and longevity of Mini LED displays.

Mini LED PCB substrates are commonly used in various applications such as high-resolution displays, backlighting units for LCD panels, automotive lighting, and general lighting products where high brightness, compact size, and energy efficiency are important considerations.

Mini Led PCB Substrate Manufacturer

What are the Mini LED PCB Design Guidelines?

Designing PCBs for Mini LEDs requires careful consideration of various factors to ensure optimal performance and reliability. Here are some key design guidelines:

- Thermal Management: Adequate heat dissipation is critical for Mini LED performance and longevity. Ensure the PCB design allows for efficient heat transfer away from the LEDs. This can include using thermal vias, thermal pads, and heatsinks as needed.

- Electrical Routing: Plan the electrical routing to minimize signal interference and maintain signal integrity. Keep high-speed traces as short and direct as possible to reduce signal degradation.

- Component Placement: Place components strategically to minimize signal crosstalk and interference. Place Mini LEDs with proper spacing to achieve uniform illumination and avoid hot spots.

- Power Supply Design: Design a robust power supply system to provide stable and clean power to the Mini LEDs. Consider factors such as voltage regulation, current capacity, and noise filtering.

- Grounding: Implement a solid grounding scheme to minimize ground loops and electromagnetic interference (EMI). Use a star grounding topology if necessary to reduce noise.

- PCB Material Selection: Choose PCB materials with good thermal conductivity and electrical properties suitable for Mini LED applications. High thermal conductivity materials such as metal core PCBs may be preferred for improved heat dissipation.

- Trace Width and Impedance Control: Size traces appropriately for the current carrying capacity and impedance requirements of the Mini LEDs. Use controlled impedance routing for high-speed signals to maintain signal integrity.

- Solder Mask and Silkscreen: Apply solder mask and silkscreen markings carefully to avoid covering critical areas or obstructing LED light emission.

- Reliability Considerations: Design the PCB with reliability in mind, considering factors such as mechanical stress, vibration, and environmental conditions. Use appropriate soldering techniques and conformal coating if needed for protection against moisture and contaminants.

- Testing and Validation: Perform thorough testing and validation of the PCB design to ensure it meets performance specifications and reliability requirements. This may include electrical testing, thermal testing, and functional testing of the Mini LED system.

Following these guidelines can help ensure the successful design and implementation of Mini LED PCBs for various applications.

What is the Mini LED PCB Fabrication Process?

The fabrication process for Mini LED PCBs involves several steps, similar to the fabrication process for standard PCBs. Here’s a general overview of the process:

- Design Preparation: Before fabrication begins, the PCB design is prepared using CAD (Computer-Aided Design) software. This includes designing the layout of the Mini LEDs, electrical traces, and other components, as well as defining the dimensions and specifications of the PCB.

- Material Selection: Select the appropriate materials for the PCB substrate based on factors such as thermal conductivity, electrical properties, and mechanical strength. Common materials include FR-4 (a type of fiberglass-reinforced epoxy laminate), metal core PCBs (MCPCBs), and ceramic substrates.

- Panelization: Multiple PCB designs may be combined into a single panel to optimize manufacturing efficiency. The individual PCBs are arranged and spaced appropriately within the panel layout.

- Film Generation: Using the PCB design data, films are generated for each layer of the PCB, including the copper traces, solder mask, and silkscreen layers. These films serve as templates for subsequent manufacturing steps.

- Inner Layer Processing: For multi-layer PCBs, inner layers are fabricated first. This involves laminating copper foil onto both sides of the substrate, then using a process called photolithography to transfer the circuit pattern onto the copper layers using the films generated earlier.

- Through-Hole Plating (if applicable): If the PCB design includes through-hole components, holes are drilled through the substrate, and a conductive material such as copper is plated onto the hole walls to provide electrical connections between layers.

- Outer Layer Processing: Outer layers of the PCB are processed similarly to the inner layers, including the application of copper traces, solder mask, and silkscreen markings using photolithography.

- Etching: Excess copper is removed from the PCB surfaces using an etching process, leaving behind only the copper traces and pads defined by the circuit pattern.

- Surface Finishing: Surface finishing processes such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or immersion tin may be applied to improve solderability and protect the copper traces from oxidation.

- Final Inspection: The finished PCB panels are inspected for defects, including visual inspection, electrical testing, and dimensional checks to ensure they meet the specified quality standards.

- Separation: Individual PCBs are separated from the panel using methods such as routing, V-scoring, or laser cutting, depending on the panelization method used.

- Quality Assurance: Random samples of the finished PCBs may undergo further testing and inspection to ensure consistency and quality across the production batch.

Once the Mini LED PCBs have been fabricated, they are ready for assembly, where the Mini LEDs and other components are soldered onto the PCBs to create the final Mini LED display or lighting system.

How do you manufacture a Mini LED PCB?

Manufacturing a Mini LED PCB involves similar processes to those used for standard PCBs, with some specific considerations for accommodating Mini LEDs. Here’s a step-by-step overview of the manufacturing process for a Mini LED PCB:

- Design Preparation: Begin with the PCB design process, considering the placement of Mini LEDs, electrical traces, and other components. Ensure that the design meets the requirements for thermal management, electrical connectivity, and mechanical support.

- Material Selection: Choose the appropriate PCB substrate material based on factors such as thermal conductivity, dielectric properties, and mechanical strength. High thermal conductivity materials like metal core PCBs or ceramic substrates are often preferred for Mini LED applications to aid in heat dissipation.

- Panelization: Multiple PCB designs may be combined into a single panel to optimize manufacturing efficiency. Arrange the individual PCB designs within the panel layout, leaving adequate space between them.

- Film Generation: Generate the films for each layer of the PCB, including the copper traces, solder mask, and silkscreen layers, based on the PCB design data.

- Inner Layer Processing: For multi-layer PCBs, start by fabricating the inner layers. This involves laminating copper foil onto both sides of the substrate and using photolithography to transfer the circuit pattern onto the copper layers.

- Through-Hole Drilling (if applicable): If through-hole components are part of the design, drill holes through the substrate at specified locations. These holes will later be plated to provide electrical connections between layers.

- Through-Hole Plating (if applicable): Plate the drilled holes with a conductive material such as copper to create vias that establish electrical connections between different layers of the PCB.

- Outer Layer Processing: Apply copper traces, solder mask, and silkscreen markings to the outer layers of the PCB using photolithography, similar to the inner layer processing.

- Etching: Remove excess copper from the PCB surfaces using an etching process, leaving behind only the copper traces and pads defined by the circuit pattern.

- Surface Finishing: Apply surface finishing processes such as HASL, ENIG, or immersion tin to improve solderability and protect the copper traces from oxidation.

- Mini LED Placement and Soldering: After surface finishing, Mini LEDs are placed onto the PCB at their designated positions. They are then soldered onto the PCB using reflow soldering or other appropriate methods.

- Component Assembly: Any additional components, such as resistors, capacitors, or connectors, are placed and soldered onto the PCB as per the design requirements.

- Final Inspection: Inspect the finished Mini LED PCBs for defects, including visual inspection, electrical testing, and dimensional checks to ensure they meet quality standards.

- Separation: If the Mini LED PCBs were panelized, separate them into individual PCBs using methods such as routing, V-scoring, or laser cutting.

- Packaging and Shipping: Once inspection is complete, package the Mini LED PCBs appropriately for protection during shipping, and send them to the assembly line for further integration into end products or distribution to customers.

Throughout the manufacturing process, quality control measures are implemented to ensure that the Mini LED PCBs meet performance specifications and reliability requirements.

How much should a Mini LED PCB Substrate cost?

The cost of a Mini LED PCB substrate can vary widely depending on several factors such as the size, complexity, material, quantity, and manufacturing processes involved. Here are some key considerations that can influence the cost:

- Size and Complexity: Larger PCBs with more complex designs tend to be more expensive due to increased material and manufacturing costs.

- Material: The choice of PCB substrate material can significantly impact the cost. High thermal conductivity materials like metal core PCBs or ceramic substrates are generally more expensive than standard FR-4 substrates.

- Layer Count: Multi-layer PCBs are typically more expensive than single-layer or double-layer PCBs due to the additional manufacturing steps involved.

- Surface Finish: Different surface finishes such as HASL, ENIG, or immersion tin can have varying costs associated with them, with ENIG typically being more expensive than HASL, for example.

- Quantity: Economies of scale apply, meaning that larger production runs generally result in lower per-unit costs. Ordering higher quantities can often lead to volume discounts.

- Manufacturing Processes: Additional manufacturing processes such as through-hole plating, impedance control, or specialty solder mask colors can add to the overall cost.

- Quality Standards: PCBs manufactured to higher quality standards or with tighter tolerances may come with a higher price tag.

- Supplier and Location: The choice of PCB manufacturer and their location can also affect the cost. Suppliers in regions with lower labor and overhead costs may offer more competitive pricing.

As a rough estimate, Mini LED PCB substrates can range from a few dollars for simple designs in small quantities to tens or even hundreds of dollars for larger, more complex designs in larger quantities. It’s recommended to obtain quotes from multiple PCB manufacturers to get a better understanding of the specific cost for your project based on its requirements and specifications.

What is a Mini LED PCB Substrate base material?

The base material for a Mini LED PCB substrate can vary depending on the specific requirements of the application. However, certain materials are commonly used due to their properties that are well-suited for Mini LED applications. Here are some of the common base materials for Mini LED PCB substrates:

- FR-4 (Fire Retardant 4): FR-4 is a widely used epoxy-based laminate material reinforced with fiberglass. It offers good electrical insulation properties, mechanical strength, and affordability. FR-4 is suitable for many Mini LED applications, especially those that do not require exceptionally high thermal conductivity.

- Metal Core PCB (MCPCB): Metal core PCBs feature a metal core, typically aluminum or copper, which provides excellent thermal conductivity compared to standard FR-4 substrates. MCPCBs are often preferred for Mini LED applications where efficient heat dissipation is crucial to maintain LED performance and longevity.

- Ceramic Substrates: Ceramic substrates such as aluminum oxide (Al2O3) or aluminum nitride (AlN) offer even higher thermal conductivity than metal core PCBs. They are well-suited for Mini LED applications requiring exceptional thermal management capabilities, such as high-power LED arrays or high-brightness displays.

- Flexible Substrates: Flexible PCB substrates made of materials like polyimide are used in applications where flexibility or bendability is required. Flexible substrates can conform to non-flat surfaces, making them suitable for certain Mini LED applications such as curved displays or wearable devices.

The choice of base material depends on factors such as thermal management requirements, mechanical constraints, cost considerations, and the specific performance characteristics needed for the Mini LED application. Designers typically select the base material that best balances these factors to achieve optimal performance and reliability for their Mini LED PCB designs.

Which company makes Mini LED PCB Substrates?

Some companies manufacture Mini LED PCB substrates, including well-known electronic manufacturers such as Kingboard Tech, JLCPCB, AT&S, and DuPont. These companies have advanced manufacturing equipment and technology to provide various types of Mini LED PCB substrates to meet different customer needs.

As for our company, we can also produce Mini LED PCB substrates. We have an experienced engineering team and professional manufacturing equipment to customize various types of Mini LED PCB substrates according to customer requirements. Our production process strictly follows international standards to ensure reliable product quality. We use advanced materials and manufacturing technologies to meet the requirements of Mini LED applications for thermal management, electrical performance, and mechanical strength.

The Mini LED PCB substrates we provide have the following features:

- High thermal conductivity: We use high-quality metal or ceramic substrates to ensure excellent thermal conductivity of Mini LED PCB substrates, effectively reducing the operating temperature of LEDs and improving their performance and lifespan.

- Excellent electrical performance: Our Mini LED PCB substrates have good electrical insulation and signal transmission characteristics, ensuring stable and reliable LED operation.

- Precision machining:We have advanced processing equipment and technology to achieve precise circuit patterns and hole processing, ensuring the quality and stability of Mini LED PCB substrates.

- Strong reliability: We adopt strict quality control systems and perfect testing methods to ensure that each Mini LED PCB substrate meets customer requirements and standards, with excellent reliability.

- Customized services: We can customize various types and specifications of Mini LED PCB substrates according to customer specific requirements, providing personalized solutions to meet the needs of different customers.

Through the Mini LED PCB substrates produced by our company, customers can obtain high-quality, reliable, and high-performance products, providing reliable technical support and assurance for their Mini LED applications.

What are the 7 qualities of good customer service?

Good customer service is essential for building strong relationships with customers and fostering loyalty. Here are seven qualities that are typically associated with excellent customer service:

- Responsiveness:Good customer service involves promptly addressing customer inquiries, concerns, and requests. Whether it’s answering phone calls, responding to emails, or interacting on social media, being responsive shows that you value your customers’ time and are committed to helping them in a timely manner.

- Empathy: Empathy is the ability to understand and share the feelings of others. Customer service representatives who demonstrate empathy are better able to connect with customers on a personal level, show understanding of their needs and concerns, and provide appropriate support and solutions.

- Professionalism: Professionalism encompasses various aspects of behavior, including courtesy, respect, and integrity. Maintaining a professional demeanor when interacting with customers instills confidence and trust, enhancing the overall customer experience.

- Knowledgeability: Customers expect customer service representatives to have a thorough understanding of the products or services being offered, as well as relevant policies and procedures. Being knowledgeable allows representatives to provide accurate information, address inquiries effectively, and offer valuable assistance to customers.

- Problem-Solving Skills: Effective problem-solving skills are crucial for resolving customer issues and addressing complaints. Customer service representatives should be equipped to identify root causes, explore solutions, and take proactive steps to resolve problems in a timely manner, leaving customers satisfied with the outcome.

- Flexibility: Every customer interaction is unique, and situations may arise that require flexibility in approach. Good customer service involves being adaptable and willing to accommodate individual customer needs and preferences, even in challenging or unexpected circumstances.

- Follow-up and Follow-through: After addressing a customer’s issue or inquiry, good customer service includes following up to ensure that the resolution was satisfactory and that the customer’s needs were met. Additionally, following through on commitments, such as promised callbacks or updates, demonstrates reliability and commitment to customer satisfaction.

By embodying these qualities, businesses can deliver exceptional customer service experiences that leave customers feeling valued, supported, and loyal.

FAQs

What is a Mini LED PCB substrate?

A Mini LED PCB substrate is a printed circuit board specifically designed to accommodate Mini LEDs. It provides electrical connections to the Mini LED chips, facilitates thermal management, and offers mechanical support for Mini LED displays or lighting systems.

What are the advantages of using Mini LED PCB substrates?

Mini LED PCB substrates offer several advantages, including improved heat dissipation, compact size, energy efficiency, and the ability to achieve high-resolution displays or high-brightness lighting with enhanced performance and reliability.

What materials are commonly used for Mini LED PCB substrates?

Common materials for Mini LED PCB substrates include FR-4 (fiberglass-reinforced epoxy laminate), metal core PCBs (MCPCBs) for better thermal conductivity, and ceramic substrates for exceptional thermal management capabilities.

How are Mini LED PCB substrates manufactured?

The manufacturing process for Mini LED PCB substrates involves several steps, including design preparation, material selection, panelization, inner layer processing, through-hole drilling and plating (if applicable), outer layer processing, etching, surface finishing, Mini LED placement and soldering, component assembly, final inspection, separation, and packaging.

What factors should be considered when designing Mini LED PCB substrates?

Important factors to consider when designing Mini LED PCB substrates include thermal management, electrical routing, component placement, power supply design, grounding, PCB material selection, trace width and impedance control, solder mask and silkscreen application, reliability considerations, and testing and validation.

How much do Mini LED PCB substrates cost?

The cost of Mini LED PCB substrates can vary depending on factors such as size, complexity, material, quantity, manufacturing processes, and supplier. Generally, prices can range from a few dollars for simple designs in small quantities to tens or hundreds of dollars for larger, more complex designs in larger quantities.

Where can I find manufacturers of Mini LED PCB substrates?

Manufacturers of Mini LED PCB substrates can be found through online directories, industry trade shows, or by directly contacting electronic manufacturing companies specializing in PCB fabrication. Popular manufacturers include Kingboard Tech, JLCPCB, AT&S, and DuPont, among others.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier