What is Microtrace High Frequency PCB?

Microtrace High Frequency PCB Supplier,Microtrace high-frequency PCBs integrate microscopic identifiers for enhanced traceability and authentication in electronic systems. These substrates, incorporating advanced materials, ensure exceptional electrical performance and reliability in high-frequency applications. With precise traceability features embedded within the substrate, Microtrace PCBs provide robust anti-counterfeiting measures and supply chain tracking. Widely used in telecommunications, aerospace, and consumer electronics, Microtrace high-frequency PCBs offer unparalleled security and reliability, meeting stringent industry standards. Their advanced design and superior performance make them essential for applications where authenticity and traceability are critical, ensuring the integrity of electronic systems and protecting against counterfeit products.

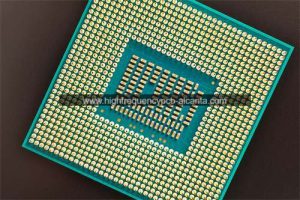

Microtrace High Frequency PCB and Ro4350B packaging substrate manufacturer, high frequency BGA substrate, using the most advanced Sap process, Msap process technology, fast delivery, stable quality.

Microtrace High Frequency PCB is a dedicated printed circuit board designed to fulfill the requirements of high-frequency applications. Widely utilized in radio frequency (RF) and microwave technologies, these PCBs cater to diverse applications such as communication devices, radar systems, satellite communications, and medical equipment.Microtrace, which could be a product or company, is focused on delivering solutions within the domain of high-frequency PCBs.

In navigating the intricacies of high-frequency environments, Microtrace High Frequency PCB undergoes a meticulous design and manufacturing process. Key considerations encompass ensuring signal stability, aligning impedance, maintaining a favorable signal-to-noise ratio, and addressing challenges related to electromagnetic compatibility. What sets Microtrace High Frequency PCB apart lies in its integration of specialized materials, precise layer stacking, and the application of advanced manufacturing techniques, collectively contributing to its superior performance in high-frequency settings.

The versatility of this product is evident in its capacity to accommodate a broad spectrum of frequencies, adeptly meeting the varied demands of different high-frequency applications. The design process is characterized by the use of minute traces and gaps, finely tuned to the specific requisites of high-frequency signals, ultimately mitigating signal loss and interference.

In essence, Microtrace High Frequency PCB represents an advanced circuit board meticulously designed for electronic applications in the high-frequency spectrum. Its purpose is to meet stringent criteria for signal transmission and overall performance in environments where precision and reliability take precedence.

Microtrace High Frequency PCB Supplier

What Drives the Functionality of Microtrace High-Frequency Package Substrate?

The operational efficiency of Microtrace High-Frequency Package Substrate is underpinned by its pivotal role in the dynamic field of electronics. This substrate significantly contributes to elevating the performance of electronic devices through various essential functions.

Primarily, Microtrace High-Frequency Package Substrate provides a sturdy foundation for the intricate integration of electronic components. Its design and composition are specifically crafted to facilitate seamless interconnections, fostering efficient communication among diverse elements within electronic devices. This aspect is instrumental in optimizing the overall functionality of electronic systems.

Furthermore, these high-frequency substrates are engineered to tackle the challenges associated with electronic signal dynamics. By incorporating advanced materials and employing precise manufacturing techniques, Microtrace ensures that the substrates exhibit minimal signal loss and interference. This characteristic is particularly crucial in applications like communication devices and radar systems, where maintaining signal integrity is of paramount importance.

An additional driving force behind its functionality lies in the substrate’s adept management of thermal considerations. Microtrace High-Frequency Package Substrate is designed to efficiently dissipate heat, preventing overheating and thereby ensuring the durability of electronic components. This is especially vital for sustaining optimal electrical performance, particularly in high-power applications or environments with demanding thermal conditions.

To sum up, the operational prowess of Microtrace High-Frequency Package Substrate emanates from its ability to seamlessly integrate electronic components, optimize signal integrity, and proficiently address thermal challenges. These substrates play an indispensable role in advancing the capabilities of electronic devices, ensuring reliability and performance across diverse electronic applications

What Diverse Types of High-Frequency Package Substrates Does Microtrace Offer?

Microtrace distinguishes itself within the electronics industry through its provision of a diverse array of high-frequency package substrates. These substrates are intricately designed to cater to the unique demands spanning various industries. The company’s commitment to flexibility and innovation is clearly demonstrated in its comprehensive suite of solutions, each meticulously crafted to address the diverse spectrum of electronic applications.

The high-frequency package substrates offered by Microtrace are notable for their use of different materials, strategically chosen to address specific industry needs. For example, materials with high dielectric constants prove beneficial for optimizing signal propagation in applications such as communication devices and radar systems. Conversely, substrates with enhanced thermal conductivity are selected for scenarios where efficient heat dissipation is paramount, such as in high-power electronic systems.

Microtrace’s substrates span a broad frequency range, showcasing versatility across a multitude of electronic applications. Substrates tailored for lower frequency ranges prioritize cost-effectiveness and ease of manufacturing, while those engineered for higher frequencies incorporate advanced materials and manufacturing techniques to minimize signal loss and interference.

A distinguishing feature of Microtrace’s strategy lies in its emphasis on customization. The company tailors high-frequency package substrates to the specific nuances of electronic applications, considering factors like impedance matching, signal integrity, and thermal management. This bespoke approach ensures a precise alignment with the unique requirements of industries such as telecommunications, aerospace, and medical electronics.

In summary, Microtrace’s diverse portfolio of high-frequency package substrates, leveraging different materials and customized solutions, positions the company as a leading provider capable of meeting the intricate and distinct needs of electronic applications. This contribution enhances overall performance and reliability in the constantly evolving technological landscape.

How Does Microtrace High-Frequency Package Substrate Compare to Conventional PCBs?

Microtrace High-Frequency Package Substrate distinguishes itself from conventional PCBs through advanced features tailored to address specific challenges associated with higher frequencies. A key differentiator lies in the materials and design employed by Microtrace, optimizing performance in industries such as telecommunications, aerospace, and emerging technologies.

Compared to traditional PCBs, Microtrace’s substrate excels in managing signal integrity at higher frequencies. High-frequency signals demand meticulous attention to impedance matching, reduced signal loss, and minimal electromagnetic interference. Microtrace achieves this through the use of specialized materials with superior dielectric properties, allowing for efficient signal propagation and minimizing attenuation.

The substrate’s unique design is geared towards providing enhanced electrical performance, crucial in applications where precision is paramount. Communication devices, radar systems, and emerging technologies present intricate challenges that demand substrates with the capability to uphold signal integrity in challenging conditions. Microtrace’s solution is purposefully crafted to fulfill these exacting requirements, demonstrating a commitment to engineering substrates that excel under stringent conditions..

Microtrace’s high-frequency package substrate provides a distinctive advantage in industries such as telecommunications and aerospace, where unwavering reliability is essential. Its efficient heat dissipation capability becomes a pivotal element in achieving optimal thermal management, particularly critical for sustaining consistent performance in high-power applications. This characteristic positions Microtrace’s substrate as a competitive choice in sectors where reliability is a non-negotiable requirement.

Moreover, the substrate from Microtrace showcases adaptability to the ever-changing landscape of emerging technologies. As these industries push the boundaries of frequency requirements, traditional PCBs may encounter limitations, while Microtrace’s solution, with its advanced materials and design, remains adaptable and capable of meeting the escalating demands of cutting-edge applications.

In summary, Microtrace High-Frequency Package Substrate stands out by offering superior signal integrity, efficient thermal management, and adaptability to the specific demands of industries such as telecommunications, aerospace, and emerging technologies. This positions it as a valuable choice where precision, reliability, and performance are paramount considerations.

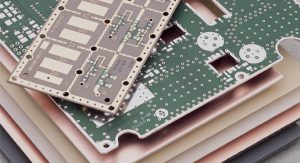

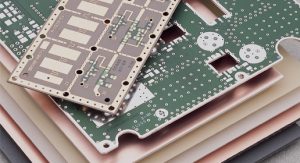

What Constitutes the Structure and Production Technologies of Microtrace High-Frequency Package Substrate?

Microtrace High-Frequency Package Substrates boast an intricate structure that incorporates several key elements to enhance precision and reliability. The advanced structure is a result of leveraging cutting-edge production technologies, including Improved HDI (High-Density Interconnect) fabrication and the innovative Improved Semi-Additive Method.

The structure of Microtrace’s high-frequency package substrate typically involves multiple layers of specialized materials with high dielectric constants, carefully chosen to optimize signal propagation. These materials contribute to the controlled impedance and reduced signal loss crucial for high-frequency applications in industries such as telecommunications and aerospace.

Improved HDI fabrication technology plays a pivotal role in achieving a highly compact and interconnected structure. This technology involves the use of advanced laser drilling and microvia processes, allowing for the creation of intricate patterns and microstructures with precision. The result is a substrate with densely packed components, minimizing signal path lengths and enhancing electrical performance.

The innovative Improved Semi-Additive Method further contributes to the precision of Microtrace’s high-frequency package substrates. This method involves selectively depositing metal only where needed, reducing material waste and enabling finer trace and space resolutions. The precise deposition of conductive materials enhances the overall performance of the substrate, particularly in terms of signal integrity.

Moreover, the integration of these production techniques enables the development of finely pitched features and intricate circuit patterns. This capability is essential in addressing the needs of emerging technologies that frequently demand smaller and more densely arranged electronic components.

In summary, Microtrace High-Frequency Package Substrate features a sophisticated composition, combining specialized materials with advanced production technologies to create a structure optimized for high-frequency applications. Improved HDI fabrication and the innovative Improved Semi-Additive Method contribute significantly to the precision and reliability of these substrates, making them well-suited for high-frequency applications in industries that demand utmost performance and reliability.

Frequently Asked Questions (FAQs)

How does it differ from conventional PCBs?

Microtrace’s substrate stands out with advanced materials and production technologies, optimizing signal integrity, precision, and reliability at higher frequencies compared to traditional PCBs.

What elements constitute its structure?

The substrate’s intricate structure involves multiple layers of specialized materials with high dielectric constants, chosen for their ability to optimize signal propagation and reduce signal loss.

What are the key production technologies involved?

Improved HDI fabrication technology and the innovative Improved Semi-Additive Method play crucial roles. Improved HDI enables compact designs through advanced laser drilling and microvia processes, while the Semi-Additive Method ensures precision in the deposition of conductive materials.

Is it suitable for emerging technologies?

Yes, the substrate’s fine-pitched features and intricate circuit patterns, achieved through advanced production technologies, make it well-suited for the evolving requirements of emerging technologies.

Can it be customized for specific applications?

Microtrace offers customization to meet specific needs, considering factors like impedance matching, signal integrity, and thermal management for diverse electronic applications.

Conclusion

In the realm of high-frequency PCB innovation, Microtrace assumes a central role as a prominent industry player. As electronic devices continually advance in speed and precision, Microtrace stands out for its adept integration of cutting-edge materials, inventive design, and meticulous manufacturing techniques.

Microtrace’s dedication to excellence is evident in its high-frequency PCB solutions, where the company strategically employs advanced materials with high dielectric constants to optimize signal propagation. Employing sophisticated manufacturing technologies, including Improved HDI fabrication and the innovative Improved Semi-Additive Method, underscores Microtrace’s commitment to crafting intricate structures that significantly enhance electrical performance.

Playing a crucial role in the pursuit of speed and precision, Microtrace tailors its high-frequency package substrates to meet the evolving demands of industries such as telecommunications, aerospace, and emerging technologies. The substrates, excelling in signal integrity, efficient thermal management, and adaptability, position Microtrace as a key facilitator in the seamless integration of electronic components.

Microtrace’s comprehensive approach extends beyond delivering a product; it encompasses providing solutions that empower electronic devices to meet the rigorous requirements of modern applications. As the industry progresses, Microtrace’s expertise in harmonizing advanced materials, innovative design, and precise manufacturing techniques solidifies its role as a cornerstone in the quest for high-performance electronic solutions.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier