What is MCL-E-795G Package substrate?

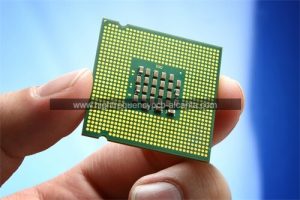

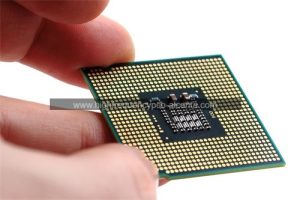

MCL-E-795G Package substrate Manufacturer,MCL-E-795G package substrate is an advanced material designed for semiconductor packaging in high-performance electronic devices. Renowned for its exceptional electrical insulation, thermal conductivity, and mechanical strength, it ensures reliable operation in demanding environments. MCL-E-795G utilizes cutting-edge manufacturing techniques to produce substrates with precise dimensions and tight tolerances. These substrates support various packaging technologies, including flip chip, wire bonding, and through-hole mounting, meeting diverse application needs. Trusted by industries such as automotive, telecommunications, and consumer electronics, MCL-E-795G package substrates empower the development of innovative electronic products with superior performance and longevity.

The MCL-E-795G Package Substrate stands as a pivotal element in the realm of integrated circuit (IC) packaging, playing a crucial role in the connectivity, support, and safeguarding of the chip. This specific substrate, designated as MCL-E-795G, signifies a nuanced model or variant tailored to possess distinct features and performance attributes.

At its core, the package substrate facilitates electrical connections, establishing a bridge between the internal circuitry of the chip and external circuits, enabling seamless communication and functionality. Beyond this, it actively contributes to heat dissipation, mitigating the risk of chip overheating and elevating overall device stability and reliability.

In the landscape of high-performance and densely packed integrated circuits, the choice of an appropriate package substrate becomes paramount for ensuring optimal electrical performance and efficient thermal management. MCL-E-795G likely embodies an advanced substrate model, characterized by a refined design catering to the specific demands of diverse application domains, such as communication technology, computing, or consumer electronics.

In essence, the MCL-E-795G Package Substrate emerges as a linchpin in IC packaging, providing indispensable support, interconnection, and protective functions for the chip. Its design and attributes, tailored to meet the distinctive requirements of particular applications and manufacturing standards, underscore its role as a bespoke solution for the chip’s intended use.

MCL-E-795G Package substrate Manufacturer

What is the function of MCL-E-795G Package Substrate?

Within the intricate domain of integrated circuit (IC) packaging, the MCL-E-795G Package Substrate assumes a pivotal and multifaceted role, embodying a spectrum of essential functions:

Fostering Electrical Synthesis: At its fundamental core, this substrate establishes an intricate web of electrical connections, acting as the conduit for signals between the chip’s internal circuitry and the external circuits. This orchestration facilitates seamless communication and collaboration, underscoring its role in the synergy of electronic components.

Providing a Robust Underpinning: Beyond its electrical function, the substrate serves as a stalwart foundation for the chip. It ensures the chip’s structural resilience, shielding it against external mechanical perturbations and environmental variables, thereby fortifying the chip’s overall structural integrity.

Meticulous Heat Governance: Addressing the exigencies of thermal dynamics, the MCL-E-795G takes center stage in dissipating the heat emanating during the chip’s operational dance. Its design intricacies likely incorporate specialized features calibrated for optimal thermal dissipation, a pivotal element in averting overheating and sustaining the chip’s functionality.

Forming a Protective Bulwark: Functioning as a protective bastion, the substrate shields the chip from potential adversaries, including moisture, contaminants, and physical exigencies. This custodial role stands as a vanguard, safeguarding the chip’s reliability and elongating its operational tenure.

Harmonizing Interconnectedness: Serving as an avant-garde platform for interconnection, the substrate orchestrates a harmonious integration between the chip and external components—be they fellow chips, connectors, or the expansive circuit board. This interlacing of components is fundamental for the chip’s seamless integration and functionality within the broader electronic ensemble.

In essence, the MCL-E-795G Package Substrate emerges as an adept conductor, choreographing a symphony of functions that collectively elevate the performance, reliability, and enduring vitality of integrated circuits in the grand tapestry of electronics.

What is the structure of MCL-E-795G Package Substrate?

Within the intricate design of the MCL-E-795G Package Substrate lies a sophisticated structure meticulously crafted to serve diverse functions crucial for the seamless integration and optimal functioning of an integrated circuit (IC). The composition of this substrate may showcase distinctive features influenced by its designated applications and manufacturing specifications.

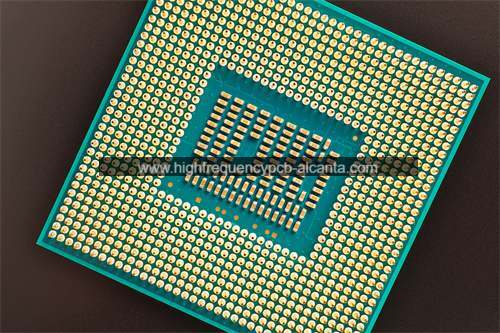

Foundational Core Layer: Positioned at the substrate’s core is a foundational layer, often crafted from materials like fiberglass-reinforced epoxy resin. This layer provides a robust groundwork for the intricate circuitry that follows.

Intricate Copper Traces: Winding across the substrate’s surface are intricate pathways of conductive copper traces. These traces act as the neural network, forming vital electrical connections between the IC chip and surrounding components.

Insulating Dielectric Layers: Enveloping the copper traces are dielectric layers, commonly composed of materials like polyimide or epoxy resin. These layers serve as insulators, warding off unintended short circuits, offering structural reinforcement, and contributing to effective thermal regulation.

Protective Solder Mask: Strategically applied, a solder mask shields the copper traces, leaving designated areas exposed for soldering during assembly. This protective barrier serves as a safeguard against inadvertent electrical connections.

Enhanced Surface Finish: The substrate’s surface may undergo specialized finishing, such as gold or tin, enhancing solderability and ensuring resilient electrical connections.

Vertical Connectivity Via Structures: Ingeniously embedded via structures, characterized by small holes filled with conductive material, facilitate the vertical flow of electrical signals. This three-dimensional design accommodates intricate circuit configurations.

Designated Component Pads: Serving as anchor points, pads are strategically positioned on the substrate for the secure attachment of the IC chip and other electronic components. These pads play a pivotal role in establishing both mechanical and electrical connections.

Potential Encapsulation Layer: Depending on the application, an additional encapsulation layer might be incorporated for heightened protection. This layer envelops the entire substrate, enhancing durability and fortifying against external influences.

The nuanced materials and layering of the MCL-E-795G Package Substrate are likely tailored to meet the unique demands of its application domain, be it in high-performance computing or telecommunications. This intricate structural amalgamation collectively ensures peak electrical performance, efficient thermal management, and unwavering reliability in supporting the integrated circuit’s functionality.

What is the manufacturing technology of MCL-E-795G Package Substrate?

The manufacturing technology intricacies behind the MCL-E-795G Package Substrate are closely guarded by the manufacturer and held as proprietary information. However, offering a broader perspective, we can explore the general manufacturing processes involved in crafting sophisticated package substrates for integrated circuits.

Initial Substrate Crafting: The manufacturing journey commences with the meticulous preparation of substrate material. Usually, a composite material like fiberglass-reinforced epoxy resin is methodically layered to shape the foundational core of the substrate.

Precision Copper Crafting: The subsequent phase entails the creation of intricate copper traces on the substrate. This is achieved through advanced techniques like photolithography, employing a light-sensitive material to transfer the desired copper trace pattern onto the substrate with precision.

Deploying Dielectric Layers: Essential for insulation and structural support, dielectric layers are delicately deposited onto the substrate. Materials such as polyimide or epoxy resin are commonly chosen to enhance these layers’ insulation properties.

Vias Formation: Vias, acting as conduits for vertical connections between different substrate layers, are meticulously crafted. This involves drilling precise holes and infusing them with conductive material to establish essential connections.

Solder Mask Application: A protective solder mask is thoughtfully applied, strategically covering specific areas of the substrate. This ensures that designated regions are exposed for soldering during subsequent assembly, serving as a safeguard against unintended electrical connections.

Surface Finishing Finesse: The substrate’s surface undergoes finishing touches to augment solderability. Common finishes, such as gold or tin applications, are employed to ensure resilient and dependable electrical connections.

Precise Component Integration: The IC chip and other electronic components find their secure positions on designated pads of the substrate through exacting soldering techniques. This step demands meticulous precision to establish both mechanical and electrical connections seamlessly.

Optional Encapsulation Layer: Depending on specific requirements, an additional encapsulation layer may be introduced. This envelops the entire substrate, providing an extra layer of defense against environmental factors and potential physical damage.

The manufacturing technology underpinning advanced package substrates, like the MCL-E-795G, likely involves a combination of highly precise and automated processes. This ensures not only consistency and reliability but also optimal performance in diverse application scenarios. It’s crucial to note that the exact intricacies of these manufacturing processes are proprietary and exclusive to the manufacturer.

How does MCL-E-795G Package Substrate differ from traditional PCBs?

The MCL-E-795G Package Substrate distinguishes itself from conventional printed circuit boards (PCBs) through its specialized role in supporting integrated circuits (ICs). Several key differences set it apart:

Distinctive Application Focus:

MCL-E-795G Package Substrate: Tailored for the specific task of IC packaging, it serves as a dedicated platform to mount and interconnect IC chips. Its design intricacies are optimized to meet the unique requirements of IC integration.

Traditional PCBs: Versatility is a hallmark, as traditional PCBs cater to a broad spectrum of electronic applications, providing support for a variety of components beyond ICs.

Precision in Design Complexity:

MCL-E-795G Package Substrate: The design is intricately specialized, involving precise arrangements of copper traces, vias, and dielectric layers to align with the specific IC it supports.

Traditional PCBs: While capable of complexity, PCB designs are generally more adaptable and generic, accommodating different components and system configurations.

Focus on Integration and Attachment:

MCL-E-795G Package Substrate: Primarily designed to facilitate the attachment and interconnection of IC chips, with a specialized focus on meeting the requirements of IC integration.

Traditional PCBs: Offer a flexible platform for attaching various electronic components, accommodating a broader range of elements such as resistors, capacitors, and connectors.

Material Composition Tailored for ICs:

MCL-E-795G Package Substrate: Likely composed of advanced materials specifically optimized for IC packaging, incorporating specialized composites, high-performance dielectrics, and suitable conductive materials.

Traditional PCBs: Commonly made from materials like fiberglass-reinforced epoxy or other standard laminates, chosen based on factors such as cost, rigidity, and general dielectric properties.

Incorporation of Specialized Features:

MCL-E-795G Package Substrate: May include features like advanced thermal management structures, precisely designed signal routing, and specialized pads tailored for IC attachment.

Traditional PCBs: While capable of advanced features, the focus is on accommodating a wide array of components, leading to more generalized design features.

In summary, the MCL-E-795G Package Substrate stands out as a specialized component designed explicitly for the nuanced requirements of IC packaging. In contrast, traditional PCBs showcase versatility, catering to a diverse range of electronic applications by providing a flexible platform for various components and system configurations.

What is the importance of MCL-E-795G Package Substrate in electronic engineering?

The MCL-E-795G Package Substrate holds a pivotal role in the field of electronic engineering, particularly within the domain of integrated circuit (IC) packaging. Its significance is multifaceted:

Facilitating IC Integration:

Acting as a secure foundation, the substrate provides a dedicated space for the attachment and interconnection of IC chips. This foundational role is fundamental to the functionality of electronic devices, as ICs serve as the central driving force behind diverse electronic systems.

Enabling Precise Electrical Connections:

The substrate hosts intricate networks of copper traces, facilitating precise electrical connections between the IC chip and other electronic components. This intricate web of connections ensures seamless communication within the electronic system.

Addressing Thermal Challenges:

Advanced thermal management structures within the substrate effectively dissipate heat generated during IC operation. This critical function prevents overheating, safeguarding the longevity and reliability of electronic devices.

Enhancing Structural Integrity:

Serving as a robust underpinning, the substrate bolsters the structural integrity of the IC assembly. This resilience is essential for withstanding mechanical stresses, environmental variables, and ensuring the overall durability of the electronic device.

Providing Protective Measures:

The substrate acts as a protective shield, guarding the IC against environmental elements, contaminants, and physical damage. This protective role significantly contributes to the reliability and prolonged operational life of the IC.

Precision Tailoring for Specialized Applications:

The substrate undergoes intricate design processes to meet the specific demands of IC packaging. Considerations such as signal integrity, impedance matching, and application-specific requirements are meticulously addressed. This precision is paramount for specialized electronic engineering applications.

Enabling Interconnection in Complex Systems:

In the intricate landscape of complex electronic systems, the MCL-E-795G Package Substrate plays a central role in interconnecting ICs with other components on a larger printed circuit board (PCB). This seamless interconnection ensures the harmonious operation of the entire electronic system.

Driving Technological Advancements:

Positioned at the forefront of electronic technologies, the MCL-E-795G Package Substrate represents an advanced solution tailored to meet the evolving demands of high-performance electronic devices. Its contribution extends to pushing the boundaries of innovation within the field of electronic engineering.

In summary, the MCL-E-795G Package Substrate stands as an indispensable component in electronic engineering, providing a specialized platform that influences the integration, connectivity, thermal dynamics, and protection of integrated circuits. Its impact resonates across the performance, reliability, and continual advancement of electronic systems.

What are the application prospects of MCL-E-795G Package Substrate?

The MCL-E-795G Package Substrate is on the verge of reshaping electronic engineering, demonstrating its adaptability and potential across diverse sectors:

Trailblazing High-Performance Computing:

With its intricate design and precision, the substrate is gearing up to play a pivotal role in high-performance computing. Its knack for enhancing the integration and connectivity of complex ICs signals a new era of transformative advancements in computing systems.

Igniting Innovations in Telecommunications:

In the dynamic realm of telecommunications, the substrate’s proficiency in providing precise electrical connections and supporting intricate ICs is poised to ignite innovation. It holds the promise of sculpting the future of communication systems and network equipment.

Propelling Evolution in Automotive Electronics:

Automotive electronics, renowned for their demanding specifications, discover a steadfast ally in the substrate. Its potential applications in electronic control units (ECUs), sensors, and critical components are set to propel evolution in automotive technology.

Elevating the Consumer Electronics Experience:

For consumer electronic devices such as smartphones and smart gadgets, the substrate’s ability to facilitate compact and reliable IC integration is a harbinger of enhanced device performance and an enriched user experience.

Contributing to Advancements in Medical Devices:

The substrate’s precision design and resilience position it as a linchpin in advancing medical devices. Its potential applications in medical imaging equipment and patient monitoring systems underscore its significance in the realm of healthcare technology.

Strategic Role in Aerospace and Defense Solutions:

In the critical aerospace and defense sectors, where precision is paramount, the substrate takes center stage. Its potential applications in avionics, radar systems, and other mission-critical electronic components align seamlessly with the stringent standards of these industries.

Empowering Innovations in IoT Ecosystems:

As the Internet of Things (IoT) continues its expansive journey, the substrate’s compact design and adept handling of intricate IC configurations position it as a linchpin for the development of smart devices and sensors, steering innovations in IoT applications.

Driving Progress in Emerging Technologies:

At the forefront of technological progress, the substrate is gearing up to be a driving force in emerging fields like artificial intelligence (AI), machine learning (ML), and quantum computing. Its support for complex ICs aligns seamlessly with the demands of these cutting-edge technologies.

Integral to 5G Infrastructure Evolution:

Amidst the ongoing deployment of 5G networks, the substrate emerges as a pivotal enabler for the development of 5G infrastructure components. Its role in ensuring efficient and reliable communication underscores its importance in the evolution of wireless networks.

In essence, the MCL-E-795G Package Substrate is not merely a component but a catalyst, heralding transformative changes in electronic engineering and poised to shape the future across a diverse spectrum of applications.

Conclusion

In conclusion, the MCL-E-795G Package Substrate emerges as a pivotal force in electronic engineering, poised to revolutionize diverse sectors with its intricate design and precision capabilities. Beyond being a mere component, it stands as a linchpin for transformative advancements. From high-performance computing to telecommunications, automotive electronics, and more, the substrate plays a central role in enhancing the integration and connectivity of complex ICs. It serves as a catalyst for innovations in medical devices, enriching the consumer electronics experience, and strategically contributing to aerospace and defense solutions. Moreover, its influence extends to shaping the landscape of emerging technologies such as artificial intelligence, machine learning, and quantum computing. The substrate’s integral role in the evolution of 5G infrastructure highlights its significance in advancing wireless networks. In essence, the MCL-E-795G Package Substrate embodies not just a technological component but a driving force propelling electronic engineering into new realms of possibility.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier