Global Semiconductor Substrate Manufacturer

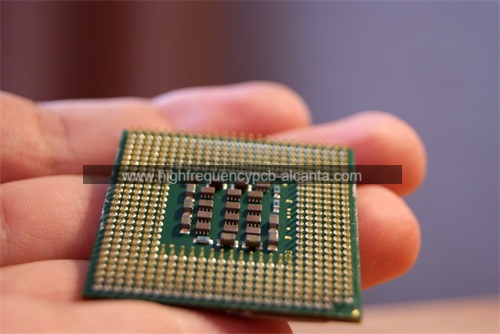

Global Semiconductor Substrate Manufacturer,Global Semiconductor Substrate is a vital component in semiconductor manufacturing, providing a foundation for integrated circuits (ICs). These substrates are produced worldwide and serve as platforms for mounting and connecting semiconductor devices. Comprising various materials such as silicon, gallium arsenide, and silicon carbide, Global Semiconductor Substrates support diverse electronic applications. They undergo precise fabrication processes to ensure uniformity and reliability. With applications spanning from consumer electronics to industrial machinery, Global Semiconductor Substrates drive innovation and enable advancements in technology. Their widespread production and distribution contribute to the global semiconductor industry’s growth and development, powering modern electronics worldwide.

The term “Global Semiconductor Substrate” refers to the primary material essential for manufacturing integrated circuits. Acting as a supportive foundation, it hosts various components within the chip. Commonly, semiconductor substrates are crafted from silicon (Si) or alternative materials like silicon-based variants and gallium nitride (GaN), chosen based on specific electrical and physical attributes. The quality and properties of the substrate directly impact the chip’s performance and cost factors. The global semiconductor substrate market holds significant strategic value, forming the backbone of the entire semiconductor industry. With continuous technological advancements, there’s an escalating demand for chips boasting heightened performance, reduced dimensions, and enhanced energy efficiency. This propels ongoing innovation and refinement in semiconductor substrate exploration and production methodologies.

Global Semiconductor Substrate Manufacturer

What are the Different Types of Global Semiconductor Substrate ?

Semiconductor substrates, the bedrock of electronic device fabrication, wield significant influence over the functionality and attributes of these technological components. Within the industry, a spectrum of semiconductor substrate types is explored, each endowed with distinctive properties and applications. Let’s delve into a snapshot of some prevalent semiconductor substrate variations:

Silicon (Si): Silicon takes center stage as the stalwart protagonist in the semiconductor substrate narrative. Its ubiquity, favorable electrical traits, and procedural simplicity establish silicon wafers as the linchpin for an array of integrated circuits (ICs) and microelectronic devices.

Gallium Arsenide (GaAs): GaAs steps into the limelight as a silicon alternative, carving out a niche in high-frequency domains such as microwave devices, high-speed transistors, and optoelectronic components. GaAs parades superior electron mobility, tailor-made for specialized applications.

Gallium Nitride (GaN): GaN, adorned with a wide bandgap, assumes roles in the high-power and high-frequency echelons. Its repertoire spans power electronics, radio frequency (RF) amplifiers, and light-emitting diodes (LEDs), often forming synergies with counterparts like silicon carbide.

Silicon Carbide (SiC): SiC takes the stage, flaunting exceptional thermal conductivity as a wide-bandgap semiconductor for high-power and high-temperature exploits. Power electronics, RF devices, and select sensor applications find SiC substrates particularly fitting, especially in demanding environments.

Sapphire: Although not a semiconductor at its core, sapphire commands attention as a substrate for gallium nitride-based devices, particularly in the LED production realm. Sapphire touts commendable thermal conductivity and visibility in the light spectrum.

Glass: Glass substrates carve out a niche in specific flexible and organic electronics scenarios. While less conventional for traditional silicon-based semiconductor devices, glass substrates gain traction in emerging technologies.

Silicon-on-Insulator (SOI): SOI technology orchestrates the strategic placement of a slender silicon layer atop an insulating foundation, often composed of silicon dioxide. This tactical maneuver mitigates parasitic capacitance, elevating the performance of select integrated circuits.

These glimpses merely scratch the surface of the diverse substrates influencing the industry. The substrate selection dances to the rhythm of the unique demands and anticipated applications of the semiconductor device in the limelight.

Global Semiconductor Substrate and IC Packaging?

In the intricate dance of electronics production, semiconductor substrates and integrated circuit (IC) packaging emerge as pivotal characters, each contributing a distinct verse to the symphony of electronic device creation.

Semiconductor substrates, spanning the commonplace silicon to the specialized gallium arsenide and silicon carbide, serve as the foundational canvas where the electronic ballet takes center stage. Beyond providing structural support, these substrates intricately map out the electrical pathways, directing the choreography of electrons within an integrated circuit.

On the flip side, IC packaging assumes the role of a vigilant guardian, enveloping the semiconductor chip in a shield against the elements – whether it’s the subtle touch of moisture, the whisper of dust, or the potential embrace of mechanical stress. Yet, it is not just a protector; it is a facilitator, nurturing the crucial electrical connections that harmonize communication and power flow between the chip and the external circuitry.

In tandem, semiconductor substrates and IC packaging form a dynamic duet, safeguarding reliability, enhancing performance, and ensuring the enduring functionality of the diverse array of modern electronic devices. Whether gracing the sleek contours of consumer gadgets or fortifying the robust systems steering industrial machinery, this duo remains steadfast at the forefront of technological progress.

How does Global Semiconductor Substrate Differ from PCBs?

In the vast expanse of electronics creation, Global Semiconductor Substrates and Printed Circuit Boards (PCBs) take on distinctive roles, each leaving an indelible mark on the canvas of electronic devices.

Functional Essence and Artistic Craft:

Semiconductor Substrates: These substrates act as the elemental canvases for the intricate choreography of semiconductor devices. Forged from materials like silicon, gallium arsenide, or silicon carbide, they undergo a symphony of processes involving lithography, etching, and doping. This creative journey breathes life into pivotal components such as transistors and integrated circuits.

Printed Circuit Boards (PCBs): In a different guise, PCBs step into the role of architectural artisans. Born from non-conductive materials like fiberglass or epoxy, they undergo a transformative process where copper layers are meticulously etched. This artistic endeavor composes the intricate symphony of circuitry, connecting a diverse ensemble of electronic components.

Components and Orchestrating Device Functionality:

Semiconductor Substrates: These substrates pulsate as the cores of semiconductor devices, providing a stage for pivotal electronic components like microprocessors, memory chips, and integrated circuits.

Printed Circuit Boards (PCBs): Conversely, PCBs take on the role of conductors of connectivity, hosting an orchestra of elements including resistors, capacitors, and integrated circuits. They carve the pathways through which signals elegantly traverse, connecting and enabling the seamless operation of electronic circuits within a diverse array of devices.

Material Harmony:

Semiconductor Substrates: Silicon, gallium arsenide, silicon carbide, and other semiconducting materials claim the spotlight as the chosen mediums for semiconductor substrates. This material selection is a nuanced dance, finely tuned to meet the specific demands of each semiconductor device.

Printed Circuit Boards (PCBs): The composition of PCBs leans toward non-conductive materials, with fiberglass, epoxy, and phenolic resin forming the canvas. Copper, shaped through meticulous etching, becomes the conductor that weaves connectivity throughout the intricate design of a PCB.

In essence, semiconductor substrates and PCBs, akin to characters in an unfolding narrative, contribute their unique tales to the symphony of electronics. Semiconductor substrates serve as the canvases for electronic artistry, while PCBs provide the structured framework and connectivity that allow this artistry to harmonize into functional electronic circuits within a diverse range of devices.

What are the Main Structures and Production Technologies of Global Semiconductor Substrate ?

In the intricate realm of semiconductor production, a diverse ensemble of substrate materials takes the lead, each narrating its story through distinctive structures and refined manufacturing techniques.

Silicon Substrates:

Structures: Silicon substrates, whether adorned with the elegance of monocrystalline or the resilience of polycrystalline structures, form the elemental canvas for semiconductor marvels. The uniform allure of monocrystalline silicon takes the spotlight.

Production Techniques: The ballet of the Czochralski (CZ) method and the Float Zone (FZ) method directs the growth of monocrystalline silicon. Sliced into wafers, these crystals undergo a meticulous journey of polishing and cleansing, refining their presence on the semiconductor stage.

Gallium Arsenide (GaAs) Substrates:

Structures: GaAs substrates, with their crystalline allure and a direct bandgap, assume a pivotal role in the realms of optoelectronics and high-frequency applications.

Production Techniques: The symphony of growth unfolds through techniques like Vertical Gradient Freeze (VGF) and the poetic dance of Liquid Encapsulated Czochralski (LEC). Subsequently, epitaxial growth takes the stage, delicately crafting layers of GaAs on the substrate.

Silicon Carbide (SiC) Substrates:

Structures: SiC substrates, with their hexagonal crystal grace, showcase remarkable thermal and electrical prowess.

Production Techniques: The sublimation epitaxy spectacle features methods such as Physical Vapor Transport (PVT) and the artistic touch of the Modified Lely method. Vaporized silicon carbide material pirouettes, condensing to form the substrate.

Sapphire Substrates:

Structures: Sapphire substrates, the single-crystal gems of aluminum oxide (Al2O3), stand with a regal hexagonal crystal structure.

Production Techniques: The grandeur of the Kyropoulos or the balletic Edge-Defined Film-Fed Growth (EFG) methods takes center stage. Sliced into wafers, these crystals undergo a polishing encore, ready for semiconductor stardom.

Glass and Polymer Substrates:

Structures: Glass and polymer substrates, flexible and transparent maestros, bask in the spotlight of flexible electronics and displays.

Production Techniques: A roll-to-roll symphony unfolds for flexible substrates, a continuous performance on grand rolls. Polymer substrates, born through techniques like spin-coating or the extrusion waltz, join hands with glass substrates, shaped through various glass-forming duets.

In this ever-evolving saga of semiconductor substrate manufacturing, the dance continues, with ongoing research refining production methods within each material category.

Frequently Asked Questions (FAQs)

How do diverse semiconductor substrates bring their unique flair to electronic device construction?

Diverse semiconductor substrates unveil their unique virtues. Silicon, a stalwart for its ubiquity, contrasts with the high electron mobility of GaAs, tailor-made for the crescendos of high-frequency applications. SiC substrates, with their thermal prowess, take center stage for power devices.

What considerations dance on the stage when selecting a semiconductor substrate?

The choreography of selection involves a nuanced play, considering material properties such as electrical and thermal conductivity, harmony with the envisioned semiconductor device, and the economic notes of manufacturing costs and availability.

Can semiconductor substrates take an encore through recycling?

Some semiconductor substrates, like silicon, await their encore through reclamation and rejuvenation after a transformative journey of processing and cleansing. Yet, the feasibility pirouettes delicately depending on the specific material and the manufacturing symphony.

Do environmental considerations take a bow in the semiconductor substrate manufacturing theater?

The semiconductor substrate manufacturing saga unfolds with a mindful nod to environmental nuances. Efforts twirl towards embracing cleaner manufacturing compositions and orchestrating an eco-conscious dance with waste management practices.

Where does one embark on a journey of discovery into the world of semiconductor substrates?

Embark on a journey of enlightenment through the pages of semiconductor industry publications, the rhythm of academic research papers, and the vibrant canvases of manufacturer datasheets and websites.

Conclusion

In the dynamic realm of semiconductor substrates, the narrative unfolds as a tapestry woven from a diverse array of materials, intricate structures, and sophisticated production techniques. From the foundational silicon to the crystalline allure of gallium arsenide and the robust thermal capabilities of silicon carbide, each substrate assumes a distinctive role in shaping the landscape of electronic devices that define our technological epoch.

Traversing the landscape of manufacturing methods, including the graceful choreography of Czochralski and the nuanced Vertical Gradient Freeze, we witness the emergence of substrates that not only provide the bedrock for semiconductor devices but also contribute to a progressive narrative emphasizing cleaner and sustainable practices.

The selection of substrates unfolds as a carefully orchestrated symphony of considerations, where material properties harmonize with economic factors, guiding the choices that underpin the creation of intricate integrated circuits, transistors, and diodes.

Environmental consciousness takes a prominent position in this narrative, with concerted efforts directed towards refining manufacturing practices and waste management. This commitment to sustainability represents a harmonious dance between technological advancement and planetary stewardship.

The question of recycling introduces an encore possibility, especially for substrates like silicon, as the industry embraces circular and eco-friendly approaches, contributing to a more sustainable trajectory.

As we draw the curtain on this exploration, the world of semiconductor substrates beckons continual exploration. Whether delving into industry publications, academic insights, or the rich tapestry of manufacturer resources, the journey into the intricacies of substrate science is an ever-evolving saga promising innovation, sustainability, and the unfolding movements in the symphony of electronic progress.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier