Global Semiconductor Packaging Manufacturer

Global Semiconductor Packaging Manufacturer,Global Semiconductor Packaging encompasses the diverse ecosystem of technologies and processes involved in protecting and interconnecting semiconductor chips. This industry segment includes various packaging types such as flip chip, ball grid array (BGA), and chip scale packaging (CSP). It plays a crucial role in enhancing chip performance, reliability, and miniaturization. Semiconductor packaging ensures electrical connections, thermal management, and protection from environmental factors. With continuous advancements in materials and techniques, global semiconductor packaging drives innovation across industries like consumer electronics, automotive, and telecommunications, shaping the future of electronic devices and enabling transformative technologies.

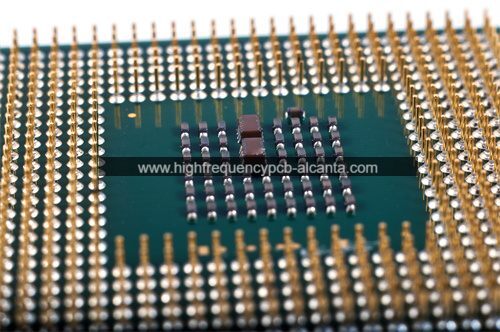

Global Semiconductor Packaging involves the meticulous art of encasing semiconductor devices, ensuring their dependability, thermal efficiency, and operational prowess. These tiny marvels are the unsung heroes within electronic gadgets, ranging from ubiquitous smartphones to the sophisticated brains of automotive electronics and computers.

Packaging semiconductor devices serves a multifaceted purpose:

Guardian Shield: Packaging transforms into a formidable guardian, shielding semiconductor devices from external foes such as moisture, contaminants, and potential mechanical mishaps, thereby ensuring their peak performance remains untarnished.

Heat Symphony: In the symphony of operation, semiconductor devices generate thermal energy. Packaging conducts an adept ballet in managing and dissipating this heat, gracefully sidestepping any risk of overheating and ensuring an encore of optimal functionality.

Electrical Nexus: Packaging dons the hat of a maestro, orchestrating the necessary conduits for semiconductor devices to establish connections with external circuitry. This harmonic connection facilitates seamless communication within the electronic ecosystem.

Diminutive Ballet: Packaging choreographs the dance of miniaturization for semiconductor devices, rendering them nimble for integration into smaller electronic apparatus, a ballet of compact elegance.

Cost-Efficient Production Waltz: By waltzing through streamlined packaging processes, there’s a noticeable crescendo in yield, paving the way for an economical, high-volume production of semiconductor devices.

Global Semiconductor Packaging waltzes through a plethora of technologies and materials, executing a deft pirouette to meet the eclectic demands of different applications. The ensemble of packaging types includes the venerable Dual In-Line Package (DIP), the sophisticated Surface Mount Device (SMD), the resilient Ball Grid Array (BGA), the minimalist Chip-on-Board (COB), and the integrative System-in-Package (SiP).

The global semiconductor packaging stage is in a perpetual state of dance, choreographing its moves to the rhythm of emerging technologies. The crucible of advancements in packaging technologies, materials, and design is pivotal for birthing more robust, compact, and energy-efficient electronic entities in this grand symphony of innovation.

Global Semiconductor packaging Manufacturer

What Role Does Global Semiconductor Packaging Play?

In the dynamic landscape of electronics, global semiconductor packaging assumes a pivotal role, akin to a conductor orchestrating a symphony of functions crucial for the seamless integration and optimal performance of semiconductor devices across diverse electronic products. Let’s explore the diverse responsibilities it undertakes:

Guardian of Fragility: Visualize semiconductor packaging as a vigilant guardian, standing resilient against environmental adversaries like moisture, contaminants, and wear. This custodianship is paramount in safeguarding the durability and reliability of semiconductor devices.

Heat Choreography: As semiconductor devices engage in their operational ballet, generating heat, packaging steps into the limelight as a seasoned choreographer. It deftly directs the graceful management and dissipation of heat, preventing overheating and ensuring sustained peak performance.

Electrical Maestro: Transitioning beyond protection, packaging transforms into a maestro, harmoniously facilitating electrical connections between the semiconductor device and external circuitry. It assumes the role of a conductor, synchronizing communication and power transfer, seamlessly integrating the semiconductor into the broader electronic composition.

Space Liberation Specialist: Packaging emerges as an artist, skillfully enabling the downsizing of semiconductor devices. This artistic touch allows for the integration of these devices into smaller electronic products, a pivotal aspect in crafting sleek and portable gadgets.

Performance Alchemist: Leveraging advanced materials and designs, certain packaging technologies act as alchemists, transmuting into enhancers of electrical performance. This alchemy translates into improved signal integrity and a reduction in electromagnetic interference (EMI), ensuring the device operates at its zenith.

Economic Navigator: Efficient packaging processes assume the role of a navigator, steering through the economic landscape. By refining yield and enabling high-volume production, packaging contributes to the economic viability of mass-producing semiconductor devices.

Innovation Catalyst: Picture semiconductor packaging advancements as catalysts for innovation in the electronics domain. They serve as gateways to novel techniques and materials, laying the foundation for the development of cutting-edge, powerful, and energy-efficient electronic devices.

Tailoring Virtuoso: Semiconductor packaging transcends a one-size-fits-all approach, morphing into a virtuoso. It tailors its approach based on the specific demands of diverse applications, from the chic realm of consumer electronics to the rugged settings of the automotive and industrial domains.

In essence, global semiconductor packaging is not merely a protective shield; it’s a nuanced symphony of functionality, a stalwart guardian of resilience, and a driving force propelling innovation, steering semiconductor devices through the ever-evolving composition of modern electronics.

What Types of Global Semiconductor Packaging Exist?

In the expansive realm of Global Semiconductor Packaging, a diverse ensemble of packaging types takes center stage, each intricately crafted to navigate the nuances and demands of the ever-evolving electronics industry. Let’s embark on a journey through some of these types, each a protagonist in the tale of safeguarding and optimizing semiconductor devices:

Dual In-Line Package (DIP): A veteran in the field, DIP boasts a classic through-hole design with two rows of pins gracefully extending from its sides. It serves as a reminiscent figure in the narrative of older electronic components.

Surface Mount Device (SMD): Breaking convention, SMD packages redefine the storyline by allowing components to pirouette directly onto the surface of a printed circuit board (PCB). This avant-garde approach eliminates traditional holes, embracing a more spatially efficient choreography.

Ball Grid Array (BGA): Emerging as a modern protagonist, BGA takes the stage with solder balls arranged in a grid pattern on its underside. Known for its stellar thermal performance, BGA elegantly dances its way into contemporary processors and integrated circuits.

Quad Flat Package (QFP): Balancing form and function, QFP graces the scene with a flat surface and leads extending gracefully from all four sides. Its versatility finds resonance in applications requiring a harmonious synthesis of size and manufacturability.

Chip-on-Board (COB): Embracing a minimalist aesthetic, COB ventures into uncharted territories by directly affixing the semiconductor chip to the PCB sans the conventional packaging attire. This approach takes the spotlight in applications where spatial efficiency is the leading choreography.

System-in-Package (SiP): Stepping into the integration spotlight, SiP takes a bow by seamlessly harmonizing multiple semiconductor devices within a singular package. This orchestrated ensemble aims to optimize performance while minimizing the overall footprint of the electronic narrative.

Small Outline Transistor (SOT): Making a cameo appearance, SOT caters to the discrete components with its compact stature, often gracing the stage in roles involving transistors and similar electronic entities.

Thin Small Outline Package (TSOP): Tailored for memory devices, TSOP takes center stage with its slender profile, weaving its narrative in applications where spatial constraints demand a lean and elegant design.

Plastic Dual In-Line Package (PDIP): Merging functionality with practicality, PDIP walks the stage with a classic DIP design but dons a plastic attire instead of ceramic, finding resonance in a multitude of electronic applications.

Ceramic Quad Flat Package (CQFP): Elevating thermal conductivity to an art form, CQFP takes a bow with its leverage of ceramic materials. It gracefully performs in applications where efficient heat dissipation stands as a critical plot point.

Plastic Quad Flat No-Lead (PQFN): Breaking free from tradition, PQFN emerges with no outward protrusions, featuring solder pads elegantly arranged on the underside. This design evolution enhances both thermal and electrical performance.

The semiconductor packaging narrative unfolds on a dynamic canvas, witnessing a constant flux of innovation to meet the crescendo of emerging technologies. Each packaging type dons a unique costume, addressing specific needs dictated by size, thermal considerations, and the distinctive requirements of various applications.

How Does Global Semiconductor Packaging Relate to IC Packaging?

Global Semiconductor Packaging and IC (Integrated Circuit) Packaging, though often used interchangeably, illuminate different facets within the intricate tapestry of the semiconductor realm. Let’s redefine their connection through a different lens:

Panoramic Encompassing vs. Laser-Focused Detailing:

Global Semiconductor Packaging: Unfurls a panoramic view, capturing the diverse spectrum of semiconductor packaging practices across the globe. It extends its narrative beyond integrated circuits, embracing a myriad of packaging methodologies tailored for various semiconductor devices.

IC Packaging: Adjusts the focus to a laser precision, delving deeply into the specific packaging intricacies designed for integrated circuits. This is a meticulous exploration of the nuances and specialized techniques dedicated to packaging these core components.

Implicit Harmony in Complexity:

Global Semiconductor Packaging inherently integrates IC Packaging within its narrative, recognizing the indispensable role of integrated circuits in the semiconductor symphony. It navigates through the complexities of semiconductor packaging practices, where IC Packaging is a crucial and intricate segment.

Embracing Diversity vs. Niche Specialization:

Global Semiconductor Packaging celebrates the diversity of packaging technologies, acknowledging the need for versatile solutions catering to various semiconductor components. It appreciates the adaptability required in a field where one size doesn’t fit all.

IC Packaging, in contrast, focuses on niche specialization. It hones in on the tailored techniques specifically crafted to meet the unique challenges posed by integrated circuits, recognizing the intricate dance required for their packaging.

Evolutionary Synchrony:

Both Global Semiconductor Packaging and IC Packaging dance in synchrony with the rhythm of technological evolution. They harmonize with advancements in materials, innovative designs, and cutting-edge manufacturing processes, shaping the ever-evolving landscape of semiconductor packaging.

In essence, while Global Semiconductor Packaging offers a broad and inclusive perspective, IC Packaging provides a finely tuned exploration of the specialized techniques dedicated to the packaging intricacies of integrated circuits. Together, they compose a narrative that unfolds the complexity and dynamism within the semiconductor packaging universe.

How Does Global Semiconductor Packaging Differ from Traditional PCBs?

Global Semiconductor Packaging and traditional Printed Circuit Boards (PCBs) are distinct players in the intricate dance of electronics, each bringing a unique set of moves to the stage. Let’s reimagine their differences through a different choreography:

Semiconductor Ballet vs. Electronic Ensemble:

Global Semiconductor Packaging: Takes center stage with a choreography focused on the delicate artistry of semiconductor devices. It crafts bespoke performances for microprocessors, memory chips, and sensors, ensuring they dance gracefully within specialized packages.

Traditional PCBs: Directs a vibrant ensemble, featuring not only semiconductors but a diverse cast of resistors, capacitors, and connectors. The narrative revolves around orchestrating their collective performance on a single electronic stage.

Soloists in the Spotlight:

Global Semiconductor Packaging: Elevates semiconductor devices as soloists in the spotlight, highlighting their strengths and vulnerabilities. The packaging narrative revolves around a tailored performance for these electronic prima donnas.

Traditional PCBs: Feature an ensemble cast where semiconductors share the limelight. The focus is on creating synergy, allowing each component to contribute to the harmonious electronic performance.

Integration Choreography:

Global Semiconductor Packaging: Executes a meticulous integration dance, ensuring semiconductor devices find their place in specialized packages. The performance includes intricate arrangements like the System-in-Package (SiP) to optimize their interactions.

Traditional PCBs: Choreograph a broader integration, orchestrating the placement and connectivity of diverse components. It’s a synchronized dance that sets the stage for the collaborative performance of the electronic ensemble.

Material and Design Symphony:

Global Semiconductor Packaging: Conducts a symphony of materials and designs, finely tuned to protect and optimize semiconductor devices. The dance includes advanced packaging materials and sophisticated interconnect technologies.

Traditional PCBs: Compose a versatile melody using materials like fiberglass-reinforced epoxy laminates. While not as specialized, the design creates a harmonious backdrop for the diverse instruments in the electronic orchestra.

Thermal Pas de Deux:

Global Semiconductor Packaging: Engages in a thermal pas de deux, gracefully managing heat through elements like heat sinks and thermal interfaces. It ensures semiconductor devices shine under the spotlight without succumbing to performance heat.

Traditional PCBs: Incorporate a subtle thermal dance, preventing overheating among the ensemble. While not the main act, it plays a crucial role in maintaining a balanced temperature throughout the performance.

Complexity and Adaptability:

Global Semiconductor Packaging: Unleashes a specialized choreography, navigating the complexity demanded by semiconductor devices. It showcases intricate packaging types like Ball Grid Array (BGA) and Quad Flat Package (QFP), tailored for individual performances.

Traditional PCBs: Stage a versatile play, accommodating a diverse range of electronic components. The complexity varies based on the electronic script, ensuring adaptability and flexibility for different acts.

In essence, Global Semiconductor Packaging and traditional PCBs contribute unique movements to the electronic dance. The former is a nuanced choreography focused on semiconductor elegance, while the latter orchestrates a dynamic ensemble performance on the electronic stage. Together, they compose a vibrant and diverse electronic performance.

What Is the Structure and Production Technology of Global Semiconductor Packaging?

The structure and production processes of Global Semiconductor Packaging unfold as a symphony of precision and innovation, meticulously crafted to shield and optimize the performance of semiconductor devices. Let’s explore the intricacies of their composition and manufacturing methodologies:

Architectural Ensemble of Global Semiconductor Packaging:

Foundational Substrate Canvas:

Anchored at the base is the substrate, sculpted from materials like silicon or ceramics. This foundational canvas provides stability, serving as the stage for a diverse range of electronic performers.

Semiconductor Opus – The Die:

The semiconductor device, often referred to as the die, houses the intricate melodies of integrated circuits, microprocessors, and other electronic virtuosos. It takes its place with grace upon the substrate.

Harmonic Interconnections – Wire Bonds or Flip-Chip Crescendo:

Establishing a harmonious connection between the die and the substrate involves the delicate interplay of wire bonds or the crescendo of flip-chip interconnections. Wire bonds deploy fine strings, while flip-chip orchestrates a direct attachment, adding a layer of sophistication.

Protective Sonata – Encapsulation or Molding:

A protective sonata unfolds as the die and wire bonds are encapsulated or molded, shielding them from environmental duress. The chosen materials, often resin or epoxy, contribute not only to protection but also to structural resilience.

Elegant Packaging Waltz:

Housed within the elegant packaging or leadframe, the encapsulated structure takes center stage. This packaging not only adds another layer of protection but also facilitates connections to the external electronic world.

Surface Mount Serenade (SMT):

The choreography may involve a surface mount serenade, where components are mounted directly onto the substrate or package surface. This eliminates the need for certain conventional connection methods.

Production Symphony:

Die Fabrication Prelude:

The symphony begins with the fabrication of semiconductor wafers through processes like photolithography. These wafers, akin to musical scores, are then delicately cut into individual die, setting the stage for the performance.

Die Attachment Crescendo:

The die is elegantly attached to the substrate, orchestrated by die attach materials such as adhesives or solder.

Interconnection Harmony – Wire Bonding or Flip-Chip Sonata:

A harmonious dance ensues as electrical connections are formed through wire bonding or the sonorous flip-chip assembly, each method lending its own unique tune to the production.

Protective Encapsulation Movement:

The assembly enters a protective movement, where encapsulation or molding becomes the protective dance, ensuring the structural and environmental robustness of the semiconductor device.

Leadframe Integration Overture:

A leadframe integration overture follows, providing additional support and insulation, preparing the semiconductor device for its grand performance.

Testing and Quality Control Crescendo:

The crescendo builds with thorough testing, covering electrical, thermal, and quality control measures. This ensures that the symphony is in perfect harmony before the semiconductor device takes its place on the global stage.

Surface Mounting Ballet (If Envisioned):

The ballet continues with surface mounting technology if envisioned, where the packaged semiconductor device elegantly graces the circuit board surface.

Final Inspection Finale:

The grand finale involves a meticulous final inspection, validating the integrity and functionality of the packaged semiconductor device. This marks the conclusion of a prodigious production journey.

In essence, the production technology of Global Semiconductor Packaging unfolds as a masterful composition, weaving together the precision of manufacturing, the artistry of material science, and the rigor of quality control. This symphony continually evolves, pushing the boundaries of device miniaturization, performance enhancement, and overall reliability.

Frequently Asked Questions (FAQs)

How Does Semiconductor Packaging Diverge from Traditional PCBs?

Unlike traditional Printed Circuit Boards (PCBs), Semiconductor Packaging takes center stage in a bespoke performance tailored to preserve and elevate the performance of semiconductor devices. It embraces specialized techniques crafted specifically for integrated circuits.

In What Ways Does Semiconductor Packaging Propel the Evolution of Electronics?

Semiconductor Packaging emerges as a driving force propelling the evolution of electronics. Its role spans from facilitating the art of miniaturization to enhancing performance and reliability. It acts as an adaptive force catering to the growing complexity of semiconductor devices.

Which Materials Take Center Stage in the Grand Production of Semiconductor Packaging?

The production involves a harmonious blend of materials, featuring the likes of silicon, ceramics, resin, epoxy, and an ensemble of metals. These materials contribute not only to structural support but also weave a tale of effective environmental protection and thermal management.

Can You Unveil the Production Choreography of Semiconductor Packaging?

The production unfolds as a symphonic masterpiece, featuring acts like die preparation, delicate die attachment, the graceful dance of wire bonding or flip-chip assembly, the encapsulating rituals of molding, leadframe integration, an exhilarating testing crescendo, and a meticulous final inspection waltz. Together, they give rise to robust and high-performance packaged semiconductor devices.

How Does Thermal Management Take Center Stage in Semiconductor Packaging?

Thermal management assumes a leading role, orchestrating a ballet to prevent overheating and ensure the optimal performance of semiconductor devices. This dance involves integrating elements like heat sinks, thermal interfaces, and other cooling mechanisms.

How Does Semiconductor Packaging Adapt to the Dynamic Technological Landscape?

Semiconductor Packaging remains nimble and adaptive through a continuous journey of research and development. This adaptation unfolds through the introduction of innovative materials, avant-garde packaging techniques, and dynamic designs, aligning seamlessly with the evolving demands of emerging technologies.

Decode the Significance of Surface Mount Technology (SMT) in Semiconductor Packaging.

Surface Mount Technology takes a leading role in this narrative, allowing components to elegantly mount directly onto the surface of a circuit board. This not only amplifies efficiency and reduces spatial constraints but also choreographs a seamless dance in the realm of automated manufacturing processes.

Conclusion

In summation, Global Semiconductor Packaging emerges as a pivotal force in the dynamic realm of electronics. Its intricate amalgamation of avant-garde technologies, encapsulation methodologies, and inventive production processes serves not only to shield but also to propel the performance of semiconductor devices, particularly integrated circuits, to new heights.

The orchestrated dance of fundamental components – from the foundational substrate to the encapsulated semiconductor die and the final packaging – unfolds as a symphony, marked by precision and adaptability. Diverse packaging technologies, including the likes of Ball Grid Array (BGA), Quad Flat Package (QFP), and System-in-Package (SiP), showcase the flexibility required to meet the demands of our increasingly intricate electronic landscape.

Semiconductor Packaging, akin to a catalyst, propels electronics into uncharted territories, acting as the enabler of miniaturization, the enhancer of performance, and the guarantor of reliability for semiconductor devices. Its indispensable role is woven into the fabric of innovations across an expansive spectrum of electronic applications.

The production journey, much like a meticulously choreographed performance, entails a series of deliberate steps — from the inception of die preparation to the crescendo of encapsulation, testing, and the final inspection. This ensures the emergence of robust and high-performance packaged semiconductor devices, poised to empower the electronic products of both the present and the future.

As we navigate the undulating terrain of technology, Semiconductor Packaging exhibits agility, embracing emerging materials, avant-garde packaging techniques, and forward-thinking designs. This adaptability solidifies its standing as a luminary, actively shaping the trajectory of electronics.

In essence, Global Semiconductor Packaging transcends its role as a mere custodian of devices; it embodies a narrative of resilience, ingenuity, and precision that reverberates in the pulse of contemporary electronics. It takes center stage in the ongoing saga of technological progress, ensuring that the devices we interact with daily transcend functionality, manifesting as a symphony of excellence.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier