CPCORE Structure Manufacturer

CPCORE Structure Manufacturer,CPCORE Structure refers to a central processing unit’s (CPU) core architecture, crucial for computing performance. It encompasses the design and layout of the CPU’s functional units, including arithmetic logic units, registers, and cache memory. The CPCORE Structure determines the CPU’s processing capabilities, efficiency, and compatibility with software applications. Advanced architectures feature multiple cores, enabling parallel processing and higher performance. CPCORE Structures undergo continuous refinement and optimization to meet evolving computing demands, ensuring efficient resource utilization and improved performance in modern computing systems, from personal computers to data centers and supercomputers.

CPCORE (Cellular Processor Core) structure denotes the intricate framework of a processing unit tailored specifically for cellular network applications. This architecture is meticulously designed to adeptly manage the intricacies of communication protocols, signal processing, and data handling intrinsic to cellular networks.

Comprising various functional blocks including baseband processing, RF interface, DSP, error correction, and control logic, CPCORE orchestrates a symphony of tasks essential for seamless communication. From modulation/demodulation to channel coding/decoding and synchronization, each component collaborates harmoniously to ensure reliable connectivity.

Efficiency is paramount in CPCORE design, with a focus on optimizing performance while minimizing power consumption, crucial for mobile devices reliant on battery power. Parallel processing, hardware acceleration, and low-power methodologies are deftly employed to achieve this delicate balance.

Furthermore, CPCORE structures are engineered for versatility, supporting multiple cellular standards such as GSM, CDMA, LTE, and 5G. This adaptability ensures compatibility with diverse network environments, fostering global connectivity.

In essence, CPCORE structure embodies a specialized processing unit finely tuned to meet the rigorous demands of cellular network operations, offering high performance, low power consumption, and adaptability to evolving communication standards.

CPCORE Structure Manufacturer

How is CPCORE Structure related to Package Substrate?

The CPCORE structure and the package substrate are closely intertwined elements in the realm of integrated circuit (IC) packaging, particularly for cellular processors.

Internal Architecture vs. Physical Foundation: The CPCORE structure delineates the intricate internal design and functional organization of the cellular processor core, emphasizing efficiency and performance optimization. Conversely, the package substrate serves as the physical foundation of the IC package, facilitating connections between internal components like the CPCORE and external interfaces.

Signal Integrity Management: The package substrate plays a critical role in maintaining signal integrity within the IC package, ensuring reliable communication for the CPCORE. By managing signal propagation and reducing interference, the substrate contributes to the seamless operation of cellular processing tasks.

Thermal Regulation Collaboration: Efficient thermal management is essential for both CPCORE and package substrate. The substrate assists in dissipating heat generated by the CPCORE during operation, ensuring optimal temperature conditions. This collaborative effort helps sustain performance and reliability over time.

Influence on Package Design: The design of the package substrate directly impacts the overall size and form factor of the IC package. This, in turn, influences considerations for the CPCORE structure. Alignment between CPCORE design requirements and substrate layout is crucial, particularly in compact mobile device designs where space constraints are paramount.

In summary, the relationship between CPCORE structure and package substrate is symbiotic, with each element playing a vital role in the efficient operation and integration of cellular processors. Together, they ensure signal integrity, manage thermal conditions, and optimize package design for diverse application scenarios.

What are the functions of CPCORE Structure?

The CPCORE structure serves as the foundation of cellular processors, fulfilling a range of crucial functions:

Baseband Processing: At its core, CPCORE manages essential signal processing tasks such as modulation, demodulation, and encoding/decoding. These operations ensure seamless data exchange within cellular networks.

RF Interface Control: It oversees communication between the processor and RF components, managing functions like frequency tuning, signal amplification, and filtering. These operations are vital for optimal RF signal transmission and reception.

Digital Signal Processing (DSP): Through dedicated DSP components, CPCORE executes intricate tasks like signal filtering, equalization, and error correction. This enhances signal accuracy and reliability.

Error Detection and Rectification: CPCORE integrates advanced algorithms to detect and rectify errors encountered during data transmission. This safeguarding ensures the integrity of transmitted data, particularly in challenging signal environments.

Control Logic Management: Embedded control logic modules govern processor operations, including task scheduling, resource allocation, and power optimization. This enhances efficiency and resource utilization.

Protocol Handling: CPCORE adeptly manages various communication protocols, including GSM, CDMA, LTE, and 5G. It handles protocol stack processing, packet routing, and network synchronization to maintain seamless connectivity.

Power Management Optimization: With integrated power management components, CPCORE regulates power consumption based on operational demands. This prolongs battery life in mobile devices and optimizes power usage across different applications.

In summary, the CPCORE structure integrates these functions seamlessly, empowering cellular processors to effectively process, transmit, and receive data across diverse cellular communication scenarios.

What are the different types of CPCORE Structure?

Different types of CPCORE structures cater to diverse needs and applications within cellular processors:

Single-Core CPCORE: This structure features a solitary processing core, suitable for simpler cellular tasks or entry-level devices with modest computational demands.

Multi-Core CPCORE: Equipped with multiple processing cores operating in parallel, this configuration enhances throughput and performance. It’s well-suited for demanding cellular applications and high-end devices requiring robust processing capabilities.

Heterogeneous CPCORE: Integrating varied processing cores within one unit, this structure balances performance and energy efficiency. By combining high-performance and low-power cores, it optimizes processing power across different tasks and applications.

Dedicated Accelerator CPCORE: Including specialized hardware accelerators for specific functions like encryption or image processing, this structure boosts overall system performance by offloading specialized computations from the main cores.

Reconfigurable CPCORE: Featuring programmable logic elements, this structure adapts dynamically to changing processing requirements or network standards. Its flexibility ensures efficient resource utilization and scalability across diverse cellular applications.

Integrated Modem CPCORE: This structure combines modem functionality directly into the CPCORE, streamlining system design and enhancing performance and power efficiency by providing an all-in-one solution for cellular communication.

These variants cater to a wide range of needs, offering tailored solutions for efficient processing and communication within cellular processors.

How does CPCORE Structure differ from PCBs?

The CPCORE structure and PCBs (Printed Circuit Boards) are pivotal components within electronic devices, each serving distinct purposes:

Functional Roles: The CPCORE structure is dedicated to organizing and designing the internal architecture of a cellular processor core. It manages tasks crucial for cellular communication, such as signal processing, protocol management, and power optimization. In contrast, PCBs provide the physical framework for electronic components to interact. They offer mechanical support and electrical connections among various elements within a device.

Integration Complexity: CPCORE structure entails intricate arrangements and integrations of internal components within a semiconductor chip or package. This optimization enhances the efficiency and performance of the cellular processor core. PCBs, meanwhile, facilitate the interconnection of components and traces on a physical board, streamlining the integration of multiple electronic elements.

Design and Manufacturing: Development of the CPCORE structure requires the expertise of semiconductor engineers and sophisticated manufacturing techniques like lithography and doping. Conversely, PCB design involves electrical engineers and specialists utilizing CAD software to plan component placement and trace routing. PCBs are manufactured through processes such as etching and soldering.

Application Scope: While the CPCORE structure is specifically tailored for cellular processors in applications like mobile devices and communication equipment, PCBs find utility across a wide spectrum of electronic devices. They are employed in industries ranging from consumer electronics to automotive, aerospace, and industrial sectors.

In essence, the CPCORE structure and PCBs play integral roles in electronic systems, each contributing uniquely to the functionality and performance of electronic devices across various applications and industries.

What are the manufacturing technologies of CPCORE Structure?

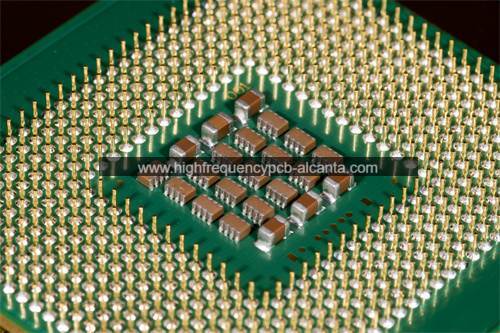

The manufacturing techniques behind the CPCORE structure involve a series of intricate processes tailored specifically for semiconductor fabrication. These methodologies are essential for shaping the detailed internal architecture of cellular processor cores. Here’s a breakdown of the key manufacturing methods involved:

Lithography: Lithography serves as a cornerstone, enabling the transfer of intricate patterns onto silicon wafers. It involves projecting precise patterns onto a light-sensitive material coating the wafer, followed by etching to define the desired features.

Deposition: Deposition techniques are utilized to coat silicon wafers with thin layers of materials necessary for forming various components of the CPCORE. Common methods include chemical vapor deposition (CVD) and physical vapor deposition (PVD), which deposit materials like silicon dioxide, metals, and semiconductor substances.

Etching: This critical step involves selectively removing materials from silicon wafers to shape the intricate features of the CPCORE structure. Techniques such as dry etching (plasma etching) and wet etching are employed to precisely remove material layers and define CPCORE components.

Doping: Doping plays a crucial role in modifying the electrical properties of silicon wafers by introducing controlled impurities into specific regions. Dopants such as boron, phosphorus, and arsenic are introduced to create semiconductor devices and CPCORE components like transistors and diodes.

Annealing: Annealing processes are essential for activating dopants and repairing any damage incurred during fabrication. Techniques like rapid thermal annealing (RTA) and furnace annealing are applied to optimize the electrical characteristics and overall performance of the CPCORE structure.

Packaging: After fabrication on silicon wafers, packaging technologies assemble and encapsulate semiconductor devices into final integrated circuit packages. Processes such as die attachment, wire bonding, and encapsulation protect the CPCORE structure and establish electrical connections with external circuitry.

In essence, these meticulously orchestrated manufacturing processes yield highly integrated and efficient cellular processor cores, powering a diverse array of applications in mobile devices, communication equipment, and beyond.

Frequently Asked Questions (FAQs):

What is a CPCORE structure?

A CPCORE structure refers to the internal architecture and design of a cellular processor core. It encompasses various components and functionalities tailored for cellular communication tasks.

What are the key components of a CPCORE structure?

Key components include signal processing units, protocol handling modules, power management circuits, control logic modules, and digital signal processing (DSP) units.

What functions does a CPCORE structure perform?

A CPCORE structure performs tasks such as signal modulation/demodulation, protocol handling (e.g., GSM, CDMA), error detection/correction, power optimization, and control logic operations.

What are the different types of CPCORE structures?

Types include single-core CPCORE, multi-core CPCORE, heterogeneous CPCORE (combining different core types), dedicated accelerator CPCORE (with specialized hardware accelerators), reconfigurable CPCORE (with programmable logic), and integrated modem CPCORE (incorporating modem functionality).

Where are CPCORE structures used?

CPCORE structures are used in cellular processors found in mobile devices, base stations, communication equipment, and other electronic systems requiring cellular connectivity.

Conclusion

In conclusion, CPCORE structures play a pivotal role in the functionality and performance of cellular processors. These structures, with their intricate internal architecture and specialized components, are tailored to meet the demands of cellular communication tasks. From signal processing to protocol handling and power optimization, CPCORE structures are designed to execute various functions essential for seamless cellular connectivity.

Manufacturing CPCORE structures involves a series of sophisticated semiconductor fabrication processes, including lithography, deposition, etching, doping, annealing, and packaging. These processes ensure the precise formation of the cellular processor core’s internal components, optimizing its efficiency and performance.

CPCORE structures come in various types, ranging from single-core to multi-core configurations, as well as heterogeneous, dedicated accelerator, reconfigurable, and integrated modem designs. Each type offers specific advantages suited to different applications and performance requirements.

Overall, CPCORE structures are integral to cellular processors found in a wide range of devices, including mobile phones, base stations, and communication equipment. By enabling efficient signal processing, protocol management, and power optimization, CPCORE structures contribute significantly to the seamless operation of cellular networks and the functionality of modern electronic devices.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier