Ceramic Substrate/Package Manufacturing

Ceramic Substrate/Package Manufacturing,Ceramic substrate/package manufacturing involves a precise and meticulous process aimed at producing durable, high-performance components for electronic devices. It begins with the selection and preparation of ceramic materials such as alumina (Al2O3), aluminum nitride (AlN), or silicon carbide (SiC). These materials are carefully mixed, formed into the desired shape using techniques like tape casting or injection molding, and then dried to remove moisture.

Next, the green ceramic parts undergo sintering at high temperatures to bond the particles together and achieve the desired density and strength. Surface treatments like polishing or metallization may be applied to enhance performance or facilitate subsequent assembly processes. In the case of ceramic packages for semiconductor devices, integrated circuits are attached using die attach adhesives, and wire bonding techniques establish electrical connections.

Encapsulation may follow to protect the components from environmental factors. Throughout the manufacturing process, rigorous quality control measures ensure that the ceramic substrates/packages meet specified requirements for dimensional accuracy, mechanical strength, electrical properties, and reliability. The result is a range of ceramic components vital for diverse electronic applications, known for their excellent thermal conductivity, electrical insulation, and mechanical durability.

What is a Ceramic Substrate/Package?

A ceramic substrate or package refers to a type of material used in electronic devices to provide structural support, electrical insulation, and thermal management for various electronic components. These substrates/packages are typically made from ceramic materials such as alumina (Al2O3), aluminum nitride (AlN), or silicon carbide (SiC). They are commonly employed in applications where high electrical insulation, thermal conductivity, and mechanical strength are required.

Here’s a brief overview of ceramic substrates/packages:

- Structural Support: Ceramic substrates/packages serve as a structural foundation for mounting and interconnecting electronic components such as integrated circuits (ICs), semiconductor chips, resistors, capacitors, and inductors. They provide a stable platform for assembling and arranging these components within electronic systems.

- Electrical Insulation: One of the key properties of ceramic materials is their excellent electrical insulation characteristics. Ceramic substrates/packages prevent electrical leakage and interference between different circuit elements, ensuring the proper functioning and reliability of electronic devices, especially in high-voltage applications.

- Thermal Management: Ceramic substrates/packages have good thermal conductivity, allowing them to efficiently dissipate heat generated by electronic components during operation. This helps in maintaining optimal operating temperatures and prolonging the lifespan of sensitive electronic devices.

- Miniaturization and Integration: Ceramic substrates/packages enable miniaturization and integration of electronic components due to their high strength-to-weight ratio and compatibility with advanced manufacturing processes such as microfabrication and thin-film deposition. They facilitate the development of compact, lightweight, and high-performance electronic systems.

- Environmental Protection: Ceramic substrates/packages can provide environmental protection for electronic components by encapsulating them within a sealed enclosure. This protects the components from moisture, dust, chemicals, and mechanical damage, enhancing their reliability and longevity in harsh operating conditions.

- Compatibility with High-Frequency Signals: Ceramic materials exhibit low dielectric loss and minimal signal attenuation at high frequencies, making them suitable for applications involving radio frequency (RF), microwave, and high-speed digital signals. Ceramic substrates/packages are widely used in telecommunications, wireless communication, radar systems, and high-frequency circuitry.

Overall, ceramic substrates/packages play a vital role in the design and manufacturing of a wide range of electronic devices, including microelectronics, power electronics, sensors, actuators, and LED lighting systems. Their unique combination of electrical, thermal, mechanical, and environmental properties makes them indispensable components in modern electronic systems.

Ceramic Substrate/Package Manufacturing

What are the Ceramic Substrate/Package Design Guidelines?

Ceramic substrate/package design guidelines are principles and recommendations aimed at optimizing the performance, reliability, and manufacturability of electronic devices utilizing ceramic substrates or packages. These guidelines are crucial for ensuring the functionality and durability of electronic components, particularly in industries such as microelectronics, semiconductor, and automotive.

Here are some common ceramic substrate/package design guidelines:

- Material Selection: Choose ceramic materials with suitable properties such as thermal conductivity, coefficient of thermal expansion (CTE), electrical insulation, mechanical strength, and chemical resistance. Common ceramics used include alumina (Al2O3), aluminum nitride (AlN), and silicon carbide (SiC).

- Thermal Management: Design the substrate/package to efficiently dissipate heat generated by electronic components. This may involve incorporating features such as thermal vias, metalized layers, or heat sinks to enhance thermal conductivity and heat dissipation.

- Electrical Design: Optimize the electrical performance of the substrate/package by considering factors like signal integrity, impedance matching, and minimizing parasitic capacitance and inductance. Proper layout and routing of traces are essential for achieving desired electrical characteristics.

- Package Size and Shape: Design the substrate/package dimensions to accommodate the electronic components and meet the overall system requirements, considering factors such as space constraints, mechanical stability, and assembly compatibility.

- Hermeticity: Ensure adequate hermetic sealing of the ceramic package to protect sensitive electronic components from moisture, dust, and other environmental contaminants. Hermetic sealing methods may include glass-to-metal sealing or brazing.

- Mechanical Durability: Design the substrate/package to withstand mechanical stresses encountered during handling, assembly, and operation. Consider factors such as mechanical shock, vibration, and thermal cycling, and incorporate features like reinforcement structures, fillets, and chamfers to improve mechanical durability.

- Manufacturability: Design for ease of manufacturing and assembly to minimize production costs and ensure consistent quality. Consider factors such as process compatibility, tooling requirements, and assembly methods during the design phase.

- Reliability and Testing: Implement design features and testing protocols to ensure the reliability and long-term performance of the ceramic substrate/package under various operating conditions and environmental stresses. This may include accelerated life testing, thermal cycling, and reliability modeling.

- Documentation and Standards Compliance: Document the design specifications, materials, manufacturing processes, and quality control procedures to facilitate traceability and compliance with industry standards and regulations.

- Feedback and Iteration: Continuously gather feedback from manufacturing, testing, and field performance to identify opportunities for improvement and refine the ceramic substrate/package design iteratively.

By following these guidelines, designers can develop ceramic substrates and packages that meet the performance, reliability, and manufacturability requirements of electronic devices, ensuring their successful integration into various applications.

What is the Ceramic Substrate/Package Fabrication Process?

The fabrication process for ceramic substrates/packages involves several steps to transform raw ceramic materials into finished components suitable for electronic applications. Here’s an overview of the typical ceramic substrate/package fabrication process:

- Material Preparation: The process begins with the preparation of raw ceramic materials such as alumina (Al2O3), aluminum nitride (AlN), or silicon carbide (SiC). These materials are often in powder form and may undergo mixing, milling, and blending to achieve the desired properties and composition.

- Forming: The prepared ceramic material is then formed into the desired shape and dimensions. Common forming techniques include dry pressing, tape casting, injection molding, and extrusion. The choice of forming method depends on factors such as complexity, precision, and batch size.

- Green Machining (Optional): In some cases, the formed ceramic parts undergo green machining, where excess material is removed to achieve the desired shape and surface finish before the parts are fully densified. Green machining may involve techniques such as milling, drilling, or grinding.

- Drying: After forming, the green ceramic parts are dried to remove moisture and organic binders. Drying may be done through air drying, oven drying, or in a controlled atmosphere to prevent cracking or warping.

- Sintering: The dried green ceramic parts are then subjected to high temperatures in a process called sintering. During sintering, the ceramic particles bond together, densify, and undergo shrinkage to form a solid, durable ceramic component. Sintering temperatures and times vary depending on the type of ceramic material and the desired properties of the final product.

- Surface Treatment (Optional): Surface treatment processes such as polishing, lapping, or metallization may be applied to the sintered ceramic parts to improve surface smoothness, electrical conductivity, or adhesion of subsequent layers.

- Metallization: Metallization involves depositing thin metal layers onto the ceramic substrate surface to create electrical conductors, bonding pads, or interconnects. Metallization techniques include screen printing, sputtering, vapor deposition, or electroplating.

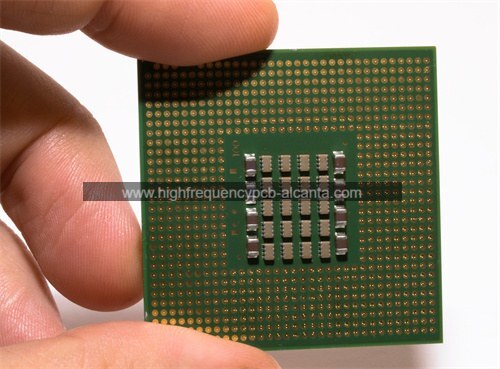

- Die Attachment and Wire Bonding (for Packages): In the case of ceramic packages for semiconductor devices, integrated circuits (ICs) or other electronic components are attached to the ceramic substrate using die attach adhesives. Wire bonding techniques are then used to connect the semiconductor die to the metallized pads on the ceramic substrate.

- Encapsulation (for Packages): If required, the assembled ceramic package may undergo encapsulation to protect the enclosed electronic components from environmental factors such as moisture, dust, and mechanical damage. Encapsulation materials such as epoxy resins or silicone gels are applied and cured to form a protective barrier.

- Quality Control and Testing: Throughout the fabrication process, quality control measures are implemented to ensure that the ceramic substrates/packages meet the specified requirements for dimensional accuracy, mechanical strength, electrical properties, and reliability. Testing may include visual inspection, dimensional measurement, electrical testing, and environmental testing (e.g., thermal cycling, humidity testing).

By following these steps, manufacturers can produce high-quality ceramic substrates and packages tailored to the specific requirements of electronic devices and applications.

How do you manufacture a Ceramic Substrate/Package?

Manufacturing ceramic substrates/packages involves a series of steps from material preparation to final assembly. Here’s a detailed overview of the typical manufacturing process:

- Material Selection and Preparation:

– Choose appropriate ceramic materials based on properties like thermal conductivity, coefficient of thermal expansion (CTE), electrical insulation, and mechanical strength.

– Raw ceramic materials, often in powder form, are carefully selected and mixed to achieve the desired composition and properties.

- Forming:

– The prepared ceramic powder is formed into the desired shape and dimensions. Common forming techniques include dry pressing, tape casting, injection molding, and extrusion.

– The choice of forming method depends on factors such as complexity, precision, and batch size.

- Green Machining (Optional):

– In some cases, the formed ceramic parts undergo green machining to remove excess material and achieve the desired shape and surface finish before sintering.

– Green machining may involve processes such as milling, drilling, or grinding.

- Drying:

– The formed ceramic parts are dried to remove moisture and organic binders. Drying may be conducted through air drying, oven drying, or in a controlled atmosphere to prevent cracking or warping.

- Sintering:

– The dried green ceramic parts are subjected to high temperatures in a furnace in a process called sintering.

– During sintering, ceramic particles bond together, densify, and undergo shrinkage to form a solid, durable ceramic component.

– Sintering temperatures and times vary depending on the type of ceramic material and desired properties.

- Surface Treatment (Optional):

– Surface treatment processes such as polishing, lapping, or metallization may be applied to the sintered ceramic parts to improve surface smoothness, electrical conductivity, or adhesion of subsequent layers.

- Metallization:

– Thin metal layers are deposited onto the ceramic substrate surface to create electrical conductors, bonding pads, or interconnects.

– Metallization techniques include screen printing, sputtering, vapor deposition, or electroplating.

- Die Attachment and Wire Bonding (for Packages):

– In the case of ceramic packages for semiconductor devices, integrated circuits (ICs) or other electronic components are attached to the ceramic substrate using die attach adhesives.

– Wire bonding techniques are then used to connect the semiconductor die to the metallized pads on the ceramic substrate.

- Encapsulation (for Packages):

– If required, the assembled ceramic package may undergo encapsulation to protect the enclosed electronic components from environmental factors.

– Encapsulation materials such as epoxy resins or silicone gels are applied and cured to form a protective barrier.

- Quality Control and Testing:

– Throughout the manufacturing process, quality control measures are implemented to ensure that the ceramic substrates/packages meet specified requirements for dimensional accuracy, mechanical strength, electrical properties, and reliability.

– Testing may include visual inspection, dimensional measurement, electrical testing, and environmental testing (e.g., thermal cycling, humidity testing).

By following these steps, manufacturers can produce high-quality ceramic substrates and packages tailored to the specific requirements of electronic devices and applications.

How much should a Ceramic Substrate/Package cost?

The cost of a ceramic substrate or package can vary significantly depending on several factors, including the material used, the manufacturing processes involved, the complexity of the design, the size and dimensions, the quantity ordered, and additional features or customization requirements.

Here are some factors that can influence the cost of ceramic substrates/packages:

- Material Cost: Different ceramic materials have varying costs. For example, alumina (Al2O3) is generally less expensive compared to more specialized ceramics like aluminum nitride (AlN) or silicon carbide (SiC).

- Manufacturing Processes: The fabrication processes involved in producing ceramic substrates/packages can affect the cost. For instance, more complex forming techniques or additional surface treatments may increase manufacturing costs.

- Design Complexity: The complexity of the substrate or package design, including features such as intricate patterns, fine tolerances, or multiple layers, can impact the manufacturing cost. More complex designs often require specialized equipment and additional processing steps, contributing to higher costs.

- Size and Dimensions: The size and dimensions of the ceramic substrate or package also influence the cost. Larger substrates/packages typically require more material and may incur higher manufacturing costs.

- Quantity Ordered: Economies of scale apply in manufacturing, so larger production runs generally result in lower unit costs. Ordering larger quantities of ceramic substrates/packages may lead to volume discounts from suppliers.

- Additional Features or Customization: Any additional features or customization requirements, such as specific surface finishes, metallization patterns, or unique packaging configurations, can add to the overall cost.

- Supplier and Geographic Location: The choice of supplier and their geographic location can affect the cost due to differences in labor costs, overhead expenses, and shipping fees.

It’s essential to consider these factors when determining the cost of ceramic substrates/packages for a particular application. For accurate pricing information, it’s advisable to consult with manufacturers or suppliers who can provide quotes based on specific project requirements. Additionally, conducting a thorough cost analysis considering all relevant factors is crucial for budgeting and decision-making purposes.

What is Ceramic Substrate/Package Base Material?

The base material of a ceramic substrate or package refers to the primary ceramic material used to construct the substrate or package body. This material forms the foundation upon which electronic components are mounted and interconnected. The choice of base material depends on various factors such as thermal conductivity, electrical insulation properties, mechanical strength, and cost. Some common ceramic materials used as base materials for substrates/packages include:

- Alumina (Al2O3): Alumina ceramic is one of the most widely used base materials for ceramic substrates/packages due to its excellent electrical insulation properties, high mechanical strength, and relatively low cost. It has good thermal conductivity and can be easily metallized for creating conductive traces and pads.

- Aluminum Nitride (AlN): Aluminum nitride ceramic offers superior thermal conductivity compared to alumina, making it well-suited for applications requiring efficient heat dissipation. It also exhibits good electrical insulation properties and high thermal stability, making it suitable for high-power electronic devices and high-frequency applications.

- Silicon Carbide (SiC): Silicon carbide ceramic is known for its exceptional thermal conductivity, high temperature stability, and resistance to thermal shock and chemical corrosion. It is commonly used in demanding applications such as power electronics, RF/microwave devices, and harsh environment sensors.

- Beryllium Oxide (BeO): Beryllium oxide ceramic offers extremely high thermal conductivity, second only to diamond among ceramics. However, its use is restricted due to health hazards associated with beryllium exposure, and safer alternatives like alumina or aluminum nitride are often preferred.

- Zirconia (ZrO2): Zirconia ceramic exhibits high mechanical strength, excellent thermal shock resistance, and good chemical stability. It finds applications in high-temperature environments and where superior mechanical properties are required.

- Glass Ceramics: Certain glass ceramic materials, such as borosilicate glass ceramics, offer a combination of properties such as low dielectric constant, excellent thermal stability, and good mechanical strength. They are used in specialized applications requiring precise dimensional control and high reliability.

The selection of the base material depends on the specific requirements of the electronic application, including thermal management needs, electrical performance, mechanical robustness, and environmental conditions. Manufacturers often evaluate these factors to determine the most suitable ceramic material for their substrates/packages to ensure optimal performance and reliability.

What are the 7 qualities of good customer service?

Good customer service is essential for building strong customer relationships, fostering loyalty, and driving business growth. Here are seven qualities that characterize effective customer service:

- Responsiveness: Customers appreciate prompt and timely responses to their inquiries, concerns, or issues. Being responsive means acknowledging customer requests promptly, providing timely updates on the status of their inquiries or concerns, and offering solutions or assistance in a timely manner.

- Empathy: Empathy involves understanding and acknowledging the emotions, perspectives, and needs of customers. Effective customer service representatives listen actively, demonstrate compassion, and validate customers’ feelings, whether they are expressing frustration, satisfaction, or uncertainty.

- Professionalism: Professionalism entails maintaining a courteous, respectful, and professional demeanor in all customer interactions. Customer service representatives should communicate clearly and effectively, adhere to company policies and procedures, and demonstrate competence and expertise in addressing customer inquiries or issues.

- Problem-solving skills: Good customer service involves effectively identifying and resolving customer problems or issues. Customer service representatives should possess strong problem-solving skills, including the ability to analyze situations, explore alternatives, and implement solutions that meet customers’ needs and expectations.

- Product knowledge: Customers expect customer service representatives to have in-depth knowledge about the products or services offered by the company. Being well-informed about product features, specifications, usage instructions, and troubleshooting tips enables representatives to provide accurate information and assistance to customers.

- Proactivity: Proactive customer service involves anticipating customers’ needs and addressing them before they become problems or issues. Customer service representatives should take initiative in identifying opportunities to enhance the customer experience, offer personalized recommendations or assistance, and follow up with customers to ensure their satisfaction.

- Adaptability: Effective customer service requires adaptability to accommodate diverse customer preferences, communication styles, and expectations. Customer service representatives should be flexible and adaptable in their approach, willing to adjust their communication or problem-solving strategies to meet the unique needs of each customer.

By embodying these qualities, organizations can deliver exceptional customer service experiences that foster customer satisfaction, loyalty, and advocacy. Investing in training and development programs to cultivate these qualities among customer service teams is crucial for achieving long-term success and competitiveness in today’s marketplace.

FAQs (Frequently Asked Questions)

What is a ceramic substrate/package?

A ceramic substrate/package is a component used in electronic packaging, typically made of ceramic materials such as alumina or aluminum nitride. It provides mechanical support, electrical insulation, and thermal management for electronic components.

What are the advantages of using ceramic substrates/packages?

Ceramic substrates/packages offer excellent thermal conductivity, electrical insulation, and mechanical strength, making them ideal for high-power applications where efficient heat dissipation is crucial. They also provide reliability and durability in harsh operating environments.

What types of electronic devices use ceramic substrates/packages?

Ceramic substrates/packages are used in various electronic devices, including power modules, LED modules, RF amplifiers, sensors, and automotive electronics.

How are ceramic substrates/packages manufactured?

The manufacturing process typically involves material preparation, shaping, printing of features (such as conductive traces and vias), firing (sintering) to densify the ceramic material, surface finishing, assembly of electronic components, testing, and packaging.

What are the key properties to consider when selecting ceramic substrates/packages?

Important properties include thermal conductivity, electrical insulation, mechanical strength, thermal expansion coefficient, surface smoothness, and compatibility with assembly processes.

How do ceramic substrates/packages compare to other packaging materials, such as plastics or metals?

Ceramic substrates/packages offer superior thermal performance compared to plastics and metals, making them suitable for high-power applications. They also provide better electrical insulation and mechanical strength compared to most plastics.

What are the common failure mechanisms in ceramic substrates/packages?

Failure mechanisms may include thermal cycling-induced cracking, delamination of layers, solder joint fatigue, and mechanical stress from handling or assembly processes. Proper design, material selection, and reliability testing can help mitigate these risks.

Can ceramic substrates/packages be customized for specific applications?

Yes, ceramic substrates/packages can be customized in terms of size, shape, layer configuration, and feature layout to meet the requirements of specific applications.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier