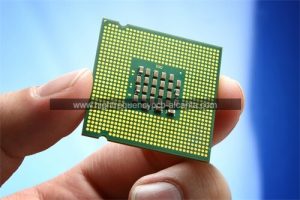

What is Ajinomoto Package Substrate?

Ajinomoto Package Substrate Manufacturer,Ajinomoto package substrates are advanced materials used in semiconductor packaging for high-performance electronic devices. These substrates offer exceptional electrical insulation, thermal conductivity, and mechanical strength, ensuring reliable operation in demanding environments. Ajinomoto utilizes cutting-edge manufacturing techniques to produce package substrates with precise dimensions and tight tolerances. Their substrates support various packaging technologies, including flip chip, wire bonding, and through-hole mounting, catering to diverse application needs. Ajinomoto package substrates are trusted by industries such as automotive, telecommunications, and consumer electronics for their quality and reliability, enabling the development of innovative electronic products with superior performance and longevity.

Ajinomoto Package Substrate (APS) stands out as a cutting-edge technology in the domain of packaging substrates, crafted by the inventive minds at Ajinomoto Co., Inc., a trailblazing Japanese company. This advanced technology takes center stage in the packaging of integrated circuits (ICs), with a primary aim to amplify packaging performance, fortify reliability, and fine-tune thermal efficiency.

Distinguished by its adept use of avant-garde materials and intricate processes, APS places a pivotal emphasis on achieving not only superior electrical performance but also agile thermal management capabilities. This often entails the incorporation of multi-layer substrate designs to hone electrical connectivity and streamline signal transmission. Furthermore, APS places a notable emphasis on thermal design to skillfully regulate the operational temperature of integrated circuits, contributing to heightened device stability and extended lifespan.

The adaptability of Ajinomoto Package Substrate spans across a broad spectrum of electronic devices, ranging from communication equipment to consumer electronics and automotive electronics. By seamlessly integrating APS into their products, manufacturers can achieve elevated echelons of performance, adeptly addressing the burgeoning demand for compact, lightweight, and high-performance electronic devices.

In essence, Ajinomoto Package Substrate symbolizes a paradigm shift in packaging technology, presenting the electronics industry with a sophisticated solution not only to enhance product competitiveness but also to fortify market positioning.

Ajinomoto Package Substrate Manufacturer

What is the Function of Ajinomoto Package Substrate?

Ajinomoto Package Substrate (APS) assumes a pivotal role in the intricate landscape of integrated circuit (IC) packaging, delivering a host of essential functions:

Enabling Electrical Harmony: APS takes the lead in establishing and refining electrical connections within an integrated circuit. Its nuanced multi-layer substrate design acts as a conductor, ensuring the smooth transmission of electrical signals across various components.

Amplifying Signal Velocity: With precision in mind, APS contributes to the optimization of signal transmission within the integrated circuit. This refinement is instrumental in maintaining the accuracy and pace of signal propagation, a cornerstone in the operational efficiency of electronic devices.

Mastering Thermal Dynamics: APS places a significant emphasis on thermal design, effectively navigating and dissipating the heat generated during the integrated circuit’s operation. This strategic approach prevents overheating, fortifies device stability, and prolongs the operational lifespan of electronic components.

Elevating Performance Metrics: By delivering superior electrical performance and adept thermal management, APS becomes a catalyst for an overall enhancement in the operational capabilities of electronic devices. This becomes particularly crucial in meeting the burgeoning demand for high-performance and reliable electronics.

Optimizing Reliability Standards: The integration of advanced materials and processes within APS contributes to the overarching reliability of integrated circuits and electronic devices. This ensures a steadfast operation and resilience in the face of diverse environmental conditions.

Championing Miniaturization and Featherweight Designs: APS seamlessly aligns with the prevailing trend of miniaturization and lightweight design in electronic devices. Its avant-garde technology paves the way for compact and lightweight packaging solutions, catering precisely to the demand for sleeker and more portable devices.

In essence, Ajinomoto Package Substrate stands as a linchpin in fine-tuning the electrical, thermal, and mechanical aspects of integrated circuit packaging. It becomes a driving force in propelling electronic devices towards a future characterized by heightened performance, unwavering reliability, and streamlined design.

What are the Different Types of Ajinomoto Package Substrate?

Ajinomoto Package Substrate (APS) unfolds as a versatile spectrum, presenting an array of types intricately fashioned to meet the distinctive needs of electronic devices. Let’s delve into the diverse variations encapsulated by APS:

Multilayer PCB (Printed Circuit Board): This prevalent manifestation of APS adopts a design strategy featuring multiple layers, enriching electrical connections and streamlining pathways for the seamless transmission of signals. Its prowess is particularly pronounced in the intricate realms of electronic systems, encompassing communication networks and computers.

Rigid-Flex: Straddling the realms of rigidity and flexibility, this APS iteration emerges as a dynamic solution, proving indispensable in scenarios necessitating adaptability due to bending or spatial constraints. Rigid-flex configurations seamlessly integrate into the realm of portable devices and settings demanding fluid layouts.

High-Frequency APS: Precision-crafted for high-frequency applications, this APS variant minimizes signal attenuation, excelling in scenarios where peak performance at elevated frequencies is imperative. Its applications extend across devices, encompassing radio frequency (RF) devices and high-speed data transmission systems.

Ceramic Substrate: Harnessing the unique attributes of ceramic materials, this APS variation stands out for its exceptional thermal conductivity. It finds a natural fit in devices with heightened heat dissipation requirements, exemplified by power amplifiers and high-power LED drivers.

Epoxy Resin Substrate: Serving as a foundational archetype within the APS realm, this variant relies on epoxy resin as its substrate material. Ubiquitously integrated into consumer electronics like smartphones and tablets, it embodies a synergy of simplicity and reliability.

These diverse APS types encapsulate nuances in material choices, layer structures, and manufacturing methodologies. Manufacturers, astute in their discernment, selectively embrace the APS variant aligning with the unique requisites of their application scenarios, thereby ensuring the robustness and optimal functionality of electronic devices.

Is there a relationship between Ajinomoto Package Substrate and IC packaging?

Ajinomoto Package Substrate (APS) and IC packaging share a symbiotic relationship within the intricate landscape of electronic devices, particularly in the domain of integrated circuits (ICs). APS, functioning as a specialized packaging substrate, brings unique attributes to the overall packaging of integrated circuits, fostering a dynamic interplay with IC packaging across various dimensions:

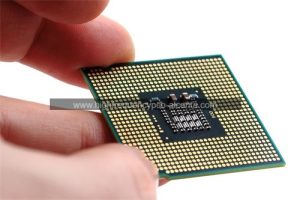

Packaging Substrate Dynamics: APS takes center stage as a specialized packaging substrate meticulously designed for integrated circuits. It acts as both the structural and electrical linchpin, facilitating the assembly and intricate interconnection of diverse IC components, including semiconductor chips, resistors, and capacitors.

Electrical Harmony: At its core, APS is engineered to promote electrical connectivity within the integrated circuit. Through its thoughtful design and distinctive material properties, APS plays a pivotal role in weaving a robust network of electrical connections among the multifaceted components nestled within the IC.

Thermal Symphony: The collaborative efforts of APS and IC packaging resonate harmoniously in the realm of thermal management. Together, they choreograph the efficient dissipation of heat, orchestrating an environment where the integrated circuit can perform optimally within prescribed temperature parameters, ensuring reliability.

Signal Ballet: APS, donning the role of a packaging substrate, exerts its influence on the graceful ballet of signal transmission within the integrated circuit. Its nuanced design elements sway the speed and integrity of signal propagation, a dance essential to the fluid functionality of the IC.

Material Artistry: Both APS and IC packaging engage in a shared pursuit of material artistry. Deliberate choices in materials reverberate through electrical properties, thermal conductivity, and mechanical strength, collectively shaping the symphony of the integrated circuit’s performance and endurance.

In essence, Ajinomoto Package Substrate emerges as a specialized artist within the canvas of IC packaging, contributing distinct hues to electrical connectivity, signal transmission, and thermal equilibrium. The dance between APS and IC packaging orchestrates the performance and resilience of integrated circuits, crafting a narrative of interconnected brilliance.

How Does Ajinomoto Package Substrate Differ from Traditional PCBs?

Ajinomoto Package Substrate (APS) sets itself apart from the conventional Printed Circuit Boards (PCBs) by embracing distinctive design philosophies, material choices, and targeted applications. Here’s a nuanced exploration of these differences:

Material Dynamics:

Traditional PCBs: Frequently anchored in materials like FR-4, a pragmatic and cost-effective epoxy glass laminate catering to broad applications.

Ajinomoto Package Substrate: APS ventures into advanced territories, potentially incorporating specialized resins and ceramics. These materials are meticulously curated to meet the specific demands of integrated circuit (IC) packaging, placing a premium on augmented thermal conductivity, reliability, and electrical prowess.

Stratified Architectures:

Traditional PCBs: Recognizable for their layered compositions, interspersing copper traces within insulating strata, with layer count contingent on circuit intricacy.

Ajinomoto Package Substrate: APS might adopt a multi-layer blueprint but diverges significantly as it tailors its strata for the nuances of IC packaging. The layering is fine-tuned to optimize electrical connectivity, signal transmission, and thermal regulation within the confined space of IC packaging.

Application Symphony:

Traditional PCBs: Versatile workhorses omnipresent in a myriad of electronic devices, forming the foundational bedrock for diverse circuitry.

Ajinomoto Package Substrate: APS assumes a specialized mantle, exclusively dedicated to IC packaging. Its design elegantly addresses the intricate demands of mounting and interconnecting IC components, especially in the realm of high-performance electronic devices that demand elevated thermal management.

Performance Choreography:

Traditional PCBs: Articulated to meet standardized performance metrics across a spectrum of electronic applications, showcasing adaptability across diverse industries.

Ajinomoto Package Substrate: Choreographed with precision for the exacting performance demands of integrated circuits. APS meticulously orchestrates superior electrical connectivity, signal fidelity, and thermal efficiency, positioning itself as an ideal candidate for applications where precision and reliability are paramount.

In essence, Ajinomoto Package Substrate emerges not just as an alternative but as a specialized maestro, weaving intricate compositions with advanced materials and a purposeful design to navigate the challenges unique to integrated circuit packaging. While traditional PCBs embrace versatility, APS stands as a refined virtuoso finely tuned for the demands of high-performance electronic devices.

What are the main structure and production technologies employed in Ajinomoto Package Substrate?

Ajinomoto Package Substrate (APS) adopts diverse structural configurations and production methodologies, finely tuned to cater to the nuanced demands of particular applications and performance benchmarks. In broad strokes, APS can embody the following key structures and manufacturing techniques:

Stratified Multilayer PCB: APS can metamorphose into a multilayered printed circuit board (PCB), where strata of conductive and insulating layers elegantly intertwine. This design choice not only accommodates intricate circuitry but also elevates the integration and prowess of the circuits.

Dynamic Rigid-Flex Design: Embracing the duality of rigidity and flexibility, APS may immerse itself in a design that gracefully marries the traits of rigid and flexible printed circuit boards. This design philosophy excels in applications demanding adaptability to bending or spatial constraints, affording a heightened degree of flexibility in device layouts.

Specialized High-Frequency APS: Tailored for applications pulsating with high frequencies, APS can assume specialized designs, adept at minimizing signal attenuation and amplifying high-frequency performance. This bespoke approach is indispensable in realms inhabited by radio frequency devices and high-speed data transmission systems.

Ceramic Symphony: APS, when orchestrated with ceramic materials, emerges as a virtuoso in thermal conductivity. This makes it an ideal choice for electronic devices thirsting for effective heat dissipation, embodying excellence in domains like power amplifiers and high-power LED drivers.

Craftsmanship in Production Technology: The crafting of APS involves an intricate ballet of advanced manufacturing technologies – from precise printing and selective etching to meticulous lamination and sophisticated surface treatments. This symphony of precision ensures the fidelity, stability, and reliability of the circuits.

In essence, the tapestry of Ajinomoto Package Substrate’s structure and production techniques unfolds as a bespoke canvas, artfully designed to harmonize with the distinctive demands of varied applications. Through a marriage of diverse materials and manufacturing finesse, APS stands poised to meet the exacting requirements of high-performance electronic devices, encompassing circuit integration, thermal equilibrium, and signal transmission.

FAQs About Ajinomoto Package Substrate

What characterizes Ajinomoto Package Substrate (APS)?

APS is a specialized substrate tailored for the intricate packaging of integrated circuits (ICs), serving as the backbone for mounting and interconnecting diverse IC components.

In what ways does APS deviate from conventional PCBs?

APS stands apart from traditional Printed Circuit Boards (PCBs) by virtue of its avant-garde materials, tailored designs, and a dedicated focus on the art of IC packaging, crafted to meet the demands of high-performance electronic devices.

What realms does APS reign over?

APS reigns supreme in the realm of IC packaging, extending its influence across a spectrum of electronic devices, from the sleek confines of smartphones to the robust architectures of communication equipment and high-performance electronic systems.

What structural symphonies can APS orchestrate?

APS can orchestrate a variety of structural symphonies, ranging from multilayered marvels to dynamic dances between rigidity and flexibility, high-frequency overtures, and even ceramic sonatas, each finely tuned to the unique demands of electronic applications.

How does APS dance with thermal dynamics in electronic devices?

APS, especially when adorned with ceramic grace, takes center stage in the ballet of thermal conductivity. Its prowess in dissipating heat elegantly contributes to the thermal equilibrium of electronic devices, a choreography crucial for devices like power amplifiers and high-power LED drivers.

What artistic maneuvers characterize APS production?

The production of APS involves a delicate ballet of advanced manufacturing arts, featuring the precise pirouettes of printing, the selective etching waltz, layered compositions akin to lamination crescendos, and the sophisticated surface treatment sonnets – a masterpiece ensuring circuit accuracy and reliability.

Can APS serenade high-frequency applications?

Indeed, APS can serenade the frequencies of the electronic realm. Its specialized designs compose a symphony that minimizes signal attenuation and amplifies the high-frequency performance, making it a virtuoso in domains governed by radio frequency devices and rapid data transmissions.

Is APS a virtuoso in the flexible electronics orchestra?

APS not only takes center stage but leads the orchestra in flexible electronics. Its ability to harmonize with the rhythm of non-planar surfaces or dance in a rigid-flex configuration makes it an essential player in the orchestra of bendable electronic devices.

How does APS contribute to the electronic signal ballet?

APS, with its thoughtful design and material grace, assumes a pivotal role in the ballet of signal transmission within integrated circuits. Its choreography minimizes signal interference, ensuring the seamless transmission of electronic messages.

Is APS a luminary in the electronic industry’s constellation?

APS has indeed ascended to luminary status within the electronic industry, becoming a stellar component in devices that demand the brilliance of high-performance integrated circuits. Its adaptability and precision make it a guiding light in various electronic constellations.

Conclusion

In summary, Ajinomoto Package Substrate (APS) emerges as a pivotal player in the intricate world of electronic packaging. Its significance lies in the careful fusion of advanced materials and precision design, orchestrating a seamless integration of integrated circuits (ICs) within high-tech devices.

APS’s adaptability is showcased through a myriad of structural configurations, from multilayered compositions to flexible choreographies. The dance of rigid-flex designs, high-frequency harmonies, and ceramic symphonies exemplifies APS’s versatility, tailored to meet the specific requirements of diverse applications.

As the lead performer in the ballet of advanced manufacturing, APS ensures the reliability and accuracy of electronic circuits, surpassing the capabilities of traditional PCBs. Its virtuosity extends beyond conventional boundaries, solidifying its role as a luminary in IC packaging.

In the ever-evolving landscape of electronic devices, APS continues to shine as a crafted masterpiece. Whether leading the orchestra in flexible electronics or serenading high-frequency applications, APS remains dedicated to excellence, facilitating the smooth transmission of signals and effective heat dissipation.

In essence, Ajinomoto Package Substrate transcends its utilitarian function, embodying a carefully curated masterpiece that seamlessly integrates with the intricacies of modern electronics, ensuring the sustained brilliance of high-performance devices.

Professional high frequency circuit board supplier

Professional high frequency circuit board supplier